Table of Contents

| Summary: Cement mortar is a homogeneous mixture of cement, sand, and water in a suitable proportion. ✔ Sometimes, the addition of admixture is required in the mortar to make it more resistant to water and chemicals. Portland cement is commonly used in the preparation of cement mortar. Priority should be given to PPC compared to OPC, looking at the situation. ✔ It should be noted that Surkhi and cinder are not chemically inert substances; hence, they can not be used as adulterants with the matrix as cement. Thus the sand only can be utilized to prepare cement mortar. |

✔ It is the strongest type of mortar and is therefore preferred for use in a different construction of structures subjected to heavy loading.

The ratio of cement to sand should generally be 1 : 3 to 1: 6 for the mortar to be workable and strong.

The use of mortars of lower cement content is unsatisfactory since any notable reduction in cement contents leads to reduced workability and less cohesion and will produce porous joints with a tendency for low frost resistance.

✔ 1: 8 cement mortar is nearly twice as strong as 1: 3 lime mortar. When used for protective plaster, cement mortar provides a waterproof layer and protects the elements covered from weathering effects.

1. Proportions of Cement Mortar

a. Masonry Construction:

Ordinary masonry work with brick/ stone as a structural unit. – 1:3 to 1:6

For reinforced brickwork – 1:2 to 1:3

For all work in moist situations – 1:3

For Architectural work – 1:6

For Load Bearing structures – 1:3 or 1:4

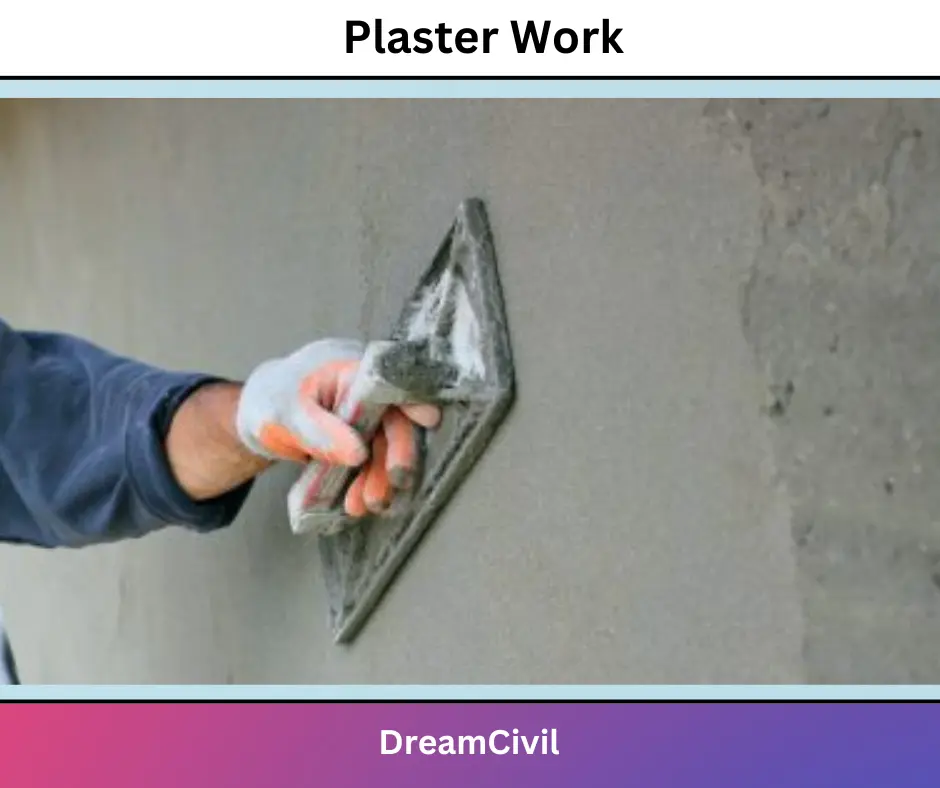

b. Plaster Work:

For External Plaster and Ceiling Plaster – 1:4

Internal Plaster (If sand is not fine, i.e. Fineness Modulus> 3) – 1:5

For Internal Plaster (if fine sand is available) – 1:6

For Ceiling – 1:3

c. Flooring Work:

Mortar ratio – 1:4 to 1:8

d. Pointing Work:

Mortar ratio – 1:1 to 1:3

Note: Cement Mortar richer than 1:3 should not be used for normal works to prevent shrinkage.

2. Grades of Cement Mortar

| Grade Name | Mix (by Loose Volume) | Compressive Strength at 28 days (in N/mm2) | |

| Cement | Sand | ||

| MM 0.7 | 1 | 8 | 0.7 to 1.5 |

| MM 1.5 | 1 | 7 | 1.5 to 2.0 |

| MM 3 | 1 | 6 | 3.0 to 5.0 |

| MM 5 | 1 | 5 | 5.0 to 7.5 |

| MM 7.5 | 1 | 4 | 7.5 to above |

3. Properties of Cement Mortar

~ It should be easily workable.

~ It should develop adequate strength in tension, compression, and bond for the work.

~ It should be durable.

~ It should not affect the durability of other materials.

~ It should be set quickly so that the speed of construction is ensured.

~ It should be cheaply available.

~ It should bind the bricks or stones to give a tight joint through which water cannot penetrate.

~ The joints formed by mortar should not develop cracks, and they should be able to maintain their appearance for quite a long time.

4. Uses of Cement Mortar

~ It is used to fill a gap between the brick and stone to make the wall weather-tight.

~ It is used to give a soft even bed between the different layers of brick and stone masonry for equal pressure distribution over the bridge.

~ It is used in pointing and plastering to protect joints and the surface of bricks and stone masonry.

~ It is used to fill up the joints of pipes.

~ It is used to generate the structure’s appearance and to hide the open joints of brickwork or stonework.

5. Preparation of Cement Mortar

a. Selection of Materials

Cement, sand, and water are required to prepare cement mortar.

Water having a ph value of 6 or less is unsuitable for mortar preparation.

b. Mixing of Materials

The followings methods prepare cement mortars:

(i) Hand mixing (ii) Machine mixing

(i) Hand mixing:

This method is usually taken when a small quantity of mortar is needed.

In this method, clean, dry sand is first spread in a uniform layer on a rigid, clean, and non-porous base prepared of masonry or flat iron sheet plates. Then the needed quantity of cement is uniformly spread.

The whole mass is mixed dry by working with spades till the entire mass becomes uniform in colour.

Depression is then formed in the centre of the mortar mix, and the required water is added to this dry mix.

Dry side material is placed on the edge of the depression containing water. It is generally done until the dry mass fully absorbs the water. Care is done not to let the water collapse the banks and flow out.

The wet mass of mortar is then worked with spades to get a mortar of unvarying consistency.

About 22.5 litres of water per bag of cement ( 50 kg bag ) is required.

Cement mortar should be prepared in small quantities that can be used before the initial setting time of the cement.

(ii) Machine mixing:

When a large quantity of mortar is required continuously at a fast rate, it is prepared by mixing the ingredients in mechanical mixers.

Process of adding materials while mixing:

~ Add half water

~ Add half sand

~ Add all the cement

~ Add 1/4 of the water (pour in slowly, running down the drum)

~ Add remaining half sand

~ Add the rest of the water to get the required consistency.

~ Always ensure the cement is wet or it sticks to the drum.

~ The drum is then revolved for a sufficient period to form a uniform mixture of the required consistency.

~ The mixed mortar is then flowed out for utilization.

c. Transporting and Placing of Mortar

The prepared mortar is transported manually in an iron pan or mechanically through a wheelbarrow, buckets, or with the help of the pump.

The media used in transportation depends upon the types and nature of the work.

Placing mortar means depositing it in its required place and position as fast as possible.

d. Curing

Curing of this mortar is generally done for 7 to 14 days. It increases the strength of mortar and reduces future problems like cracking.

| Read Also: Grades of Concrete |

6. Advantages

The advantages of Cement Mortar are as follows:

a. Because of the closed pore structure, it inhibits the circulation of moisture through it.

b. It achieves maximum efficiency in less time as compared to lime mortar.

c. It is fire-resistive.

7. Disadvantages

The disadvantages of Cement Mortar are as follows:

a. Requirement of curing for supporting hydration.

b. It has low tensile strength.

8. Precautions

Following precautions should be taken while using cement mortar.

1. It should be prepared by mixing it uniformly to a workable consistency.

2. It should be used immediately after preparation and consumed within half an hour after adding water.

3. Before laying the bricks or stones in the structure, they should be fully saturated with water. Otherwise, they may absorb the greater part of the water from the mortar, thus weakening the mortar joint due to the lack of water required for hydration.

4. The masonry or plastered surface should be continuously kept moist by sprinkling water for at least seven days.

| Read More: Water Cement Ratio |