Table of Contents

1. Introduction

Concrete is defined as the composite material that consists of a mixture of fine aggregate, coarse aggregate and binding material that has hardened over time. The binding material used may be hydraulic cement such as Portland cement or Calcium Aluminate cement, lime, putty etc. Concrete is an important type of construction material and is widely used. Due to its growing use, the suitability of the concrete must be assessed before it is used. So a number of tests on concrete is carried out. The slump test of concrete is one such test.

In general, the slump test may be defined as the test that is conducted to test the consistency of the fresh concrete.

It is the test that is carried out on the concrete mix prepared in the laboratory or the site itself to assess the consistency or the workability of the concrete.

Precisely, the slump test is used to check if an appropriate amount of water has been added to the concrete mix.

The primary objective of this test is to determine the workability of the concrete.

It is a simple test and is widely used throughout the world.

The test also serves as an indicator of the improperly mixed batch.

2. Objectives of the Slump Test

The main objectives of the slump test can be listed as follows:

1. To determine the workability of the fresh concrete before it sets.

2. To identify the improperly mixed batch of concrete.

3. General Test Procedure

The general test procedure of the slump test is briefly described below.

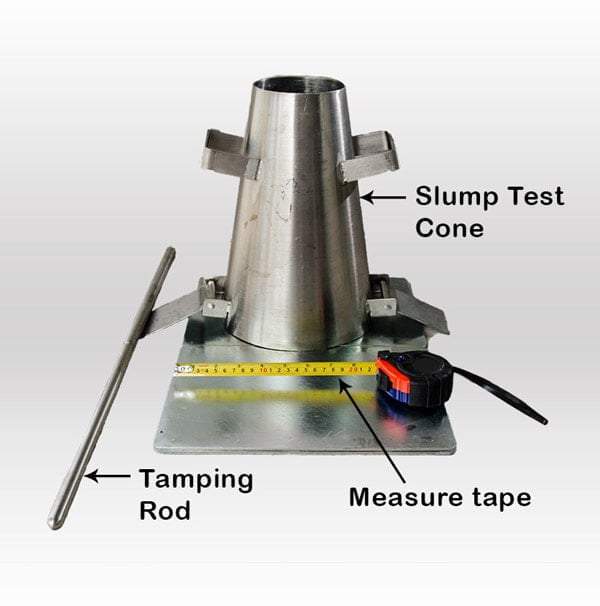

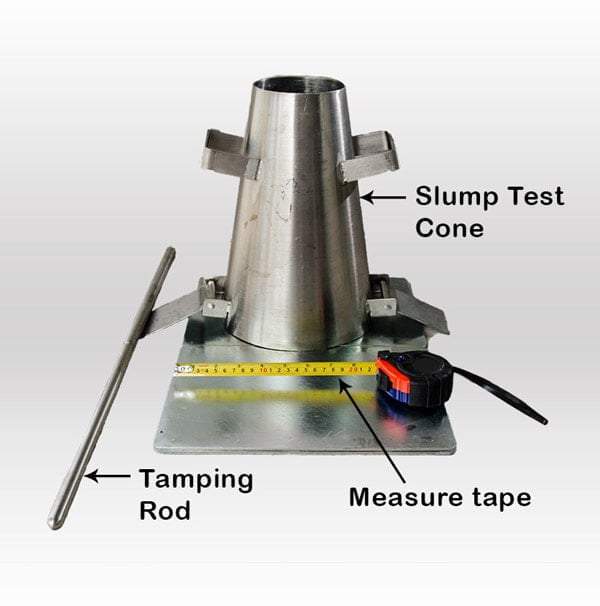

Apparatus Required

1. Mould for the slump test which includes slump cone and non-porous base plate.

2. Tamping rod.

3. Measuring scale.

4. Trowel.

Procedure

The test procedure involves the following series of steps:

1. First of all, a concrete mix of suitable grade (generally M15) is prepared.

2. The internal surface of the mould is thoroughly cleaned and is duly oiled.

3. The cleaned mould is then placed on the non-porous base plate.

4. The freshly prepared concrete mix is poured inside the mould in about four approximately equal layers.

5. Each layer of the concrete mix is tamped by the rounded end of the tamping rod with twenty-five strokes.

6. The excess of the concrete should be removed and the surface must be uniformly levelled with the trowel.

7. The leaked water or the excess mortar between the base plate and the mould is also cleaned.

8. The mould is then immediately removed vertically with utmost care.

9. Then, the slump is measured as the difference between the height of the mould and the height of the test point.

Result

The result is expressed as the vertical settlement in millimetres of subsidence of the concrete specimen during the test.

Slump for the given sample= _____mm

Interpretation of the Test Results

After the mould is removed, the following types of slump may be observed:

1. True Slump:

It is the only slump that can be measured during the test.

The measurement is done between the top of the cone to the top of the concrete after the mould has been removed.

2. Zero Slump:

Zero slump indicates the concrete mix with a very low water-cement ratio.

This indicates too dry concrete mix.

It is usually preferred for road construction.

3. Collapsed Slump:

Collapsed slump indicates the concrete mix with a very high water-cement ratio.

This indicates a too wet concrete mix.

4. Shear Slump:

Shear slump indicates that the test has to be conducted again.

| Read More: Earthen Road |

| Read More: Ranging in Surveying |