Table of Contents

We will discuss the stone dressing, its methods, and stages. Before moving to the Dressing of Stone, we will know about Quarrying.

A. What is the Quarrying of Stone?

✔ Quarrying of stones is the art of extracting stones from the rock beds. The place from which the stones are obtained (by digging or blasting) is known as a ‘Quarry.’

✔ It can be done manually using hand tools or with the help of machines.

✔ Blasting with explosives is another method used in the Quarrying of Stone.

✔ The different methods of Quarrying are:

a. By digging

b. By heating

c. By wedging

d. By blasting

| Read More: Quarrying and Methods of Quarrying of Stone |

B. What is Stone Dressing?

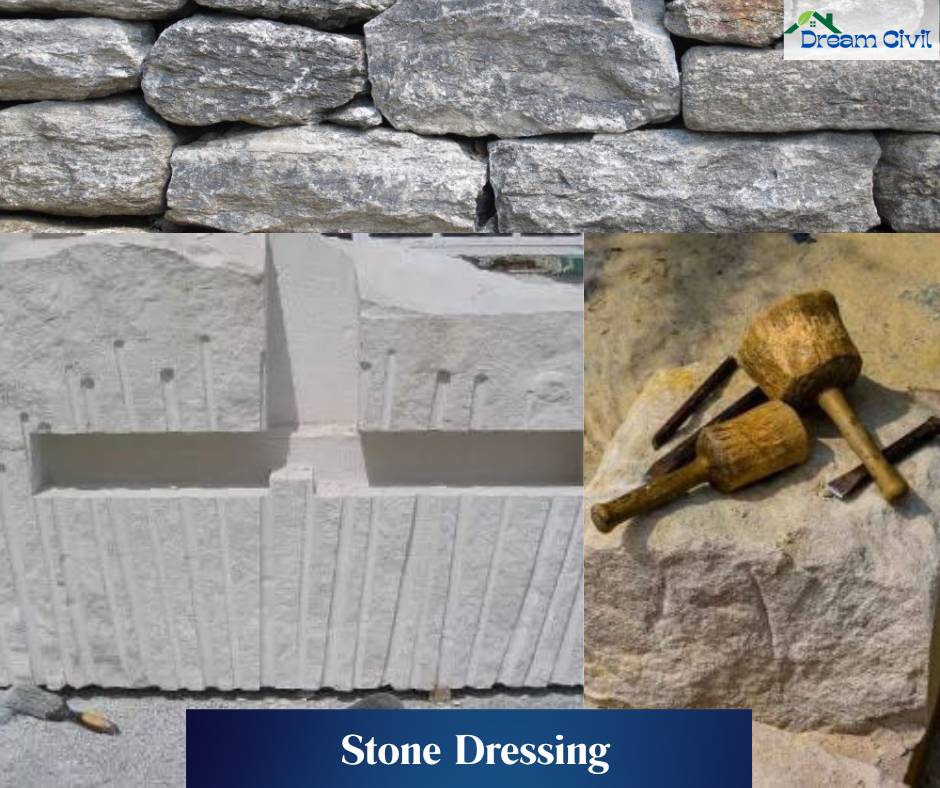

✔ Dressing is the process of giving proper size, shape, and finish to the roughly broken stones obtained from the quarry bed.

✔ The Dressing can be done manually with hand tools like Gad, hammers, chisels, etc, or also can be done using machines.

✔ Objectives of Dressing include reducing size, shaping, and obtaining an attractive finish.

| Read More: 20+ Tools used in stone dressing. |

C. What are the Stages in the Stone Dressing?

✔ Sizing: Irregular quarried rocks or stones are cut into required dimensions by removing extra portions, using hammers, chisels, or cutting machines.

✔Shaping: Extra projections in the Stone or rocks are removed to shape the Stone. This process is done after cutting of Stone.

✔ Planing: Clearing off all irregularities from the Surface is done. Simply, it includes the process of making surfaces uniform.

✔ Finishing: The stone surface is rubbed with an abrasive material like silicon carbide to achieve a smoother finish.

✔ Polishing: Stones like limestone, marble, and granite are polished by hand or machine to enhance their attractiveness.

D. What are the Main Objectives of Stone Dressing?

a. Size Reduction:

Purpose: Size reduction is done to make big rocks smaller so it becomes easier to handle them.

Process: Large rocks are broken down into smaller pieces using hammers or machines.

Importance: It helps to move and work with rocks more easily.

b. Proper Shaping:

Purpose: Proper shaping gives rocks the right shape.

Process: Tools like chisels and saws are used to cut or shape rocks.

Importance: Make sure rocks fit perfectly in buildings.

c. Proper Finish:

Purpose: A proper finish is required to improve the aesthetic of the stones or rocks.

Process: Polishing or grinding of the rocks is done to get a smooth and shiny surface.

Importance: It makes rocks look pleasant and can make them last longer.