Table of Contents

✔ Mud flooring, commonly known as Earthen or adobe flooring, is a natural and sustainable choice manipulated for centuries in various cultures worldwide.

✔ This flooring entangles mixing earth, Clay, cow or buffalo dunk, straw, and other natural materials to create a floor surface.

✔ Mud flooring offers several benefits, including cost-effectiveness, sustainability, and a unique and rustic look.

1. Introduction of Mud Flooring:

✔ A mud flooring prospect typically found in rural areas and developing countries. This type of flooring is made from an assortment of Clay, Sand, and Water and is a reasonable and eco-friendly option gaining popularity.

✔ Mud flooring has many concessions, including being a natural, renewable resource that is easy to install and sustain. It is also thermally insulating, furnishing a calm environment in summer and warmth in winter. Likewise, it is naturally resistant to fire and pests.

✔ However, mud flooring does have some drawbacks. It is not as durable as other options, such as concrete or tile, and may be prone to cracking and erosion. Also, cleaning can be challenging if improperly maintained and may harbor mold and mildew.

✔ In overview, mud flooring is a viable option for specific situations. It is an inexpensive and sustainable choice commonly used in rural areas and developing countries, as well as in eco-friendly building practices. However, it is essential to be aware of its limitations, such as its lack of durability and susceptibility to cracking and erosion.

2. Materials used in Mud Flooring

| Note: Cow and Buffalo dunk are also mixed as raw material in mud flooring. |

| Component | Description | Images |

| Earth | ✔ Locally sourced earth or soil is considered a primary component for mud flooring. ✔ The soil varies depending on its availability and composition. |  |

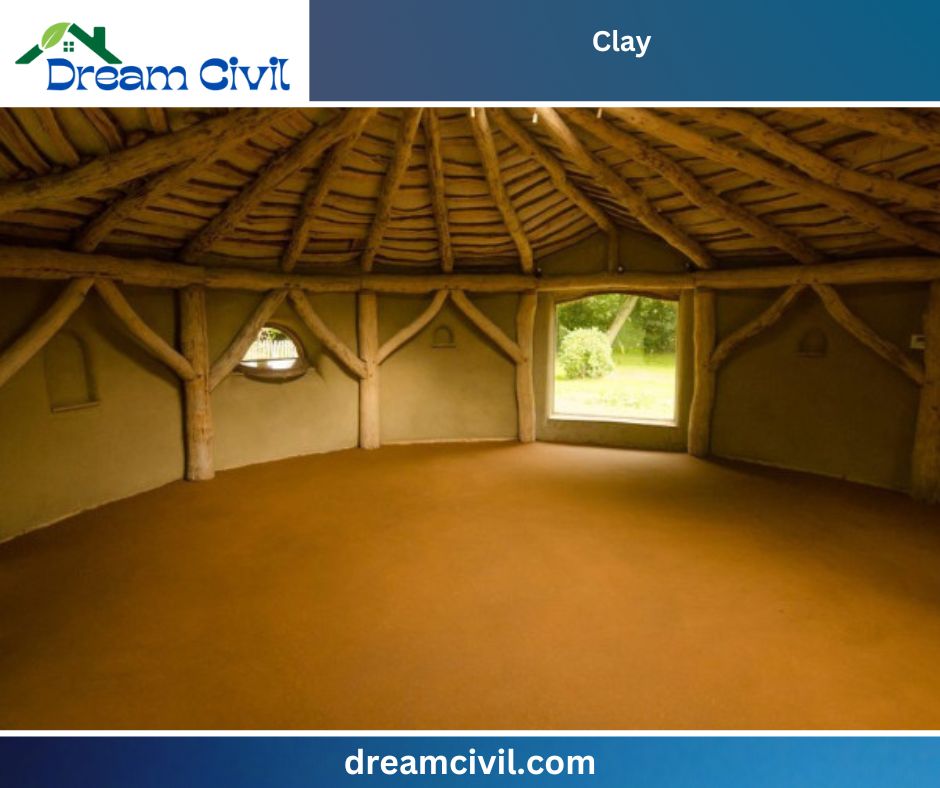

| Clay | ✔ Clay is added to the mixture to enhance cohesion and binding properties. ✔ It ensures the floor binds together and resists cracking. |  |

| Straw | ✔ Straw is sometimes incorporated to increase tensile strength to the floor and diminish cracking. |  |

| Water | ✔ Water is utilized to mix the materials into a workable consistency. |  |

3. Installation Process of Mud Flooring

| Installation Steps | Description |

| Preparation | ✔ Remove debris, loose materials, and old flooring from the existing surface. |

| Soil Selection | ✔ Choose suitable soil and sieve it if necessary to remove large particles and debris. |

| Mixing | ✔ Mix soil, Clay, Sand, straw, and Water into a moist mixture. |

| Application | ✔ Evenly spread and tamp the mud mixture onto the prepared floor surface. |

| Smoothing | ✔ Use wooden trowels or appropriate tools to smooth and level the surface. |

| Drying | ✔ Allow the mud floor to naturally dry, depending on climate and humidity, which can take several days to weeks. |

| Finishing | ✔ To enhance durability and water resistance, apply a natural sealant, like linseed oil, wax, or clay-based finish, once thoroughly dried. |

4. What are the advantages and disadvantages of Mud Flooring?

| Advantages of Mud Flooring | Considerations |

| Sustainability: Made from abundant, natural materials; minimal environmental impact | Durability: May require periodic maintenance and resealing |

| Cost-Effective: Often more affordable than conventional flooring materials | Water Sensitivity: Not suitable for consistently wet areas |

| Thermal Mass: Helps regulate indoor temperatures; energy efficient | Cracking: May develop small cracks over time, which can be repaired |

| Aesthetic Appeal: Rustic, natural aesthetic | Maintenance: Regular sweeping and occasional resealing are necessary |

| Customization: Easily customized with various colors and textures |

5. What are the characteristics of Mud Flooring?

Here are main characteristics of mud flooring are listed below:

a. Natural Insulation

✔ Mud floors possess a very natural insulating character. It permits them to hold a uniform temperature. So, it can preserve warm air in the winter and cool during the summer.

✔ The mud house possesses the best ventilation system because of its porous form. If it is sunny outside, the inside temperature would be mild.

✔ The house is ventilated due to these voids. These voids permit good air passage from the building. So, it maintains the temperature of the house.

b. Recyclability

✔ In the modern era, environmental preservation is necessary. Mud buildings are a valuable donation to our atmosphere to control global warming. Mud substitutes non-reusable material and supports reducing carbon emissions.

✔ After breaking down the building, the Mud can be reused again. Then, it evolves into a portion of compostable material.

c. Biodegradability

✔ Mud is an entirely eco-friendly material. The construction sector produces significant benefits from such materials. Due to its disposable nature, it is the most suitable choice for industries. It ultimately reduces their cost by fast-decaying ability.

d. Carbon Foot Printing

✔ Recently, it has been an essential component of construction projects. Cement ejects carbon percentage. Mud reduces carbon fumes.

6. Maintenance and Care of mud flooring

| Regular Sweeping: | ✔ Remove dust and debris with a soft broom or dust mop to prevent scratches and wear. |

| Gentle Cleaning: | ✔ Use a damp, well-wrung mop or cloth with mild, pH-neutral soap and clean Water. Avoid harsh chemicals. |

| Avoid Soaking: | ✔ Prevent excessive moisture by wiping up spills promptly and avoiding standing Water. |

| Resealing: | ✔ Periodically reseal the floor with a natural sealant like linseed oil, wax, or clay-based finish. |

| Repairing Cracks: | ✔ Minor cracks can be filled with the original mud mixture and smoothed when dry. |

| Avoid High Heels and Heavy Furniture: | ✔ Protect the surface from damage using furniture gliders and pads. |

| Area Rugs and Mats: | ✔ Use rugs in high-traffic areas and clean them regularly to prevent debris buildup. |

| Regular Inspection: | ✔ Check for wear, damage, and resealing needs. Address issues promptly. |

| Professional Maintenance: | ✔ Consider experts for extensive installations and specialized Care. |

| Footwear: | ✔ Encourage shoe removal indoors to minimize dirt and debris on the mud floor. |

7. Design and Aesthetic Possibilities of Mud Flooring

1. Natural Earth Tones: Mud floors can create a warm and inviting atmosphere with natural earth tones.

2. Custom Pigments: The shades of brown, tan, and terracotta can evoke a rustic and organic feel. You can add natural pigments or dyes to the mixture to customize the color of your mud floor.

3. Texture Variety: This allows for a broader spectrum of colors, ranging from muted pastels to rich, earthy hues. The texture of your mud floor can also be customized from a smooth, polished surface to a more textured finish that enhances its tactile appeal.

4. Decorative Patterns: Mud flooring can be decorated with hand-painted motifs, stencils, or geometric designs to add visual interest and uniqueness.

5. Inlays: Inlays of contrasting materials like stones, tiles, or mosaic pieces can create focal points or borders within the mud floor, introducing an artistic element.

6. Stenciled Artwork: Intricate designs or artwork can be stenciled onto the mud floor, transforming it into art.

7. Sealant Finish: To protect the floor, give it a subtle sheen, and enhance the depth of color, applying a natural sealant like linseed oil or wax is recommended.

8. Layered Look: Mud floors can be layered with other natural materials like stone, wood, or bamboo, creating a visually captivating and unique flooring design.

9. Rustic Elegance: When combined with wooden beams, exposed brick walls, or wrought iron fixtures, mud flooring can evoke a sense of rustic elegance.

10. Minimalist Appeal: A monochromatic mud floor with a sleek, polished finish can create a minimalist or contemporary look, providing a clean and modern backdrop.

11. Bohemian Vibes: Mud floors can align nicely with bohemian or eclectic interiors when paired with vibrant rugs, eclectic furnishings, and colorful textiles.

12. Transitions: For homes with patios or garden areas, consider using mud flooring to seamlessly transition between indoor and outdoor spaces. The continuous flooring blurs the boundaries between nature and interior living.

13. Natural Lighting: They can also create seamless transitions between indoor and outdoor spaces in homes with patios or garden areas.

14. Complementary Materials: Mud floors can showcase beauty under natural light and complement raw materials like wood, stone, or adobe walls.

15. Artisan Craftsmanship: The process of creating mud flooring often involves artisanal craftsmanship, with handprints or unique impressions adding character and telling a story.

8. Case Studies about Mud Flooring

| Case Study | Location | Features | Benefits | Images |

|---|---|---|---|---|

| Cob Cottage in Devon, UK | Devon, UK | Mud flooring throughout | ✔ The warm and inviting feel |  |

| Earthen Home in New Mexico, USA | New Mexico, USA | Mud flooring throughout | ✔ Regulates temperature; durable; sustainable |  |

| Mud Floor Workshop in California, USA | California, USA | Mud flooring throughout | ✔ Warm and inviting learning environment; natural look and feel; sustainable |  |

9. Local Sourcing and Cultural Significance of Mud Flooring:

I. Local Sourcing:

✔ Mud flooring is an advantageous flooring solution that is sustainable and can be crafted from materials available in the nearby vicinity. This approach diminishes the need for transportation and bolsters the local economy. Furthermore, utilizing materials procured from the region aids in maintaining conventional building methods.

II. Cultural Significance:

✔ Mud flooring is deeply rooted in the cultural traditions of many societies worldwide. It holds different meanings depending on the culture, ranging from simplicity and humility to the connection with the earth. Moreover, mud flooring offers a canvas for creating customary designs and patterns commonly used in certain cultures.

III. Environmental Benefits:

✔ Choosing mud flooring can have a positive impact on the environment. This renewable material has no harmful emissions during production or installation and is an excellent insulator. Using mud flooring, you can reduce your energy consumption while embracing a sustainable lifestyle.

IV. Examples of Local Sourcing and Cultural Significance:

1. Mud flooring is a popular choice for residential and commercial properties in Morocco. It combines locally sourced Mud with straw or other materials to increase its durability and strength. In Moroccan tradition, mud flooring represents modesty and unpretentiousness.

2. Mud flooring is a prevalent material in rural areas in India. It is made by mixing local Mud with cow dung to increase water resistance. This technique is a cultural symbol of connection to the earth in Indian society.

3. In China, Mud flooring is often utilized in temples and other religious structures as a traditional material. The Mud used is usually obtained locally and is sometimes mixed with rice husks to enhance its ability to withstand fire. In Chinese culture, mud flooring is considered a sacred substance.

Read Also: Weep Holes in Retaining Walls

| Verified by: Er. Bipana Kshetri Puri |