Table of Contents

Gravel may be defined as a loose aggregation of small, variously sized fragments of rock. It’s a good range of applications within the housing industry.

The gravel road is common in less developed nations, and also in rural areas of developed nations.

Gravel, alongside the sand, is employed for the manufacture of concrete, and also for mixing with asphalt as a part of the construction.

1. QUARRY ROCKS AND RECYCLED CONCRETE GRAVEL

2. COARSE GRAVEL

3. MEDIUM GRAVEL

4. FINE GRAVEL

1. Gravel Road

The roads which are made up of Gravel are considered to be Gravel Road.

Gravel Mainly Consists:

a. Surface Course

b. Base Course

c. Sub-grade

d. Side slopes from positions shown on the drawing

e. Center-line of roads

| Course | Above Required Level | Below required Level |

| Surface Course | 15 mm | 15 mm |

| Base Course | 10 mm | 10 mm |

| Sub-grade | 20 mm | 20 mm |

| Side slopes from positions shown on the drawing | 0.15 m to one side or other | |

| Center-line of roads | 0.25 m to one side or other |

a. Base Course of Gravel Road

The base course should natural river sand and gravel mixture of consistent grading and strength with the subsequent properties:

The base course material must have the below requirements in textural gradation:

Nominal Maximum Size 3″

| BS Sieve | % Passing by weight |

| 3″ | 100 |

| 2″ | 85–100 |

| 3/8″ | 37–75 |

| 3/16″ | 25–60 |

| No. 7 | 20–50 |

| No. 36 | 10–30 |

| No. 200 | 0 –15 |

b. Surface Course of Gravel Road

| Sieve Size (mm) | % Passing |

| 37.5 | 80-100 |

| 10.0 | 55–80 |

| 5.0 | 40–60 |

| 2.36 | 30–50 |

| 0.60 | 15–30 |

| 0.75 | 5–15 |

3. Construction of Gravel Roads

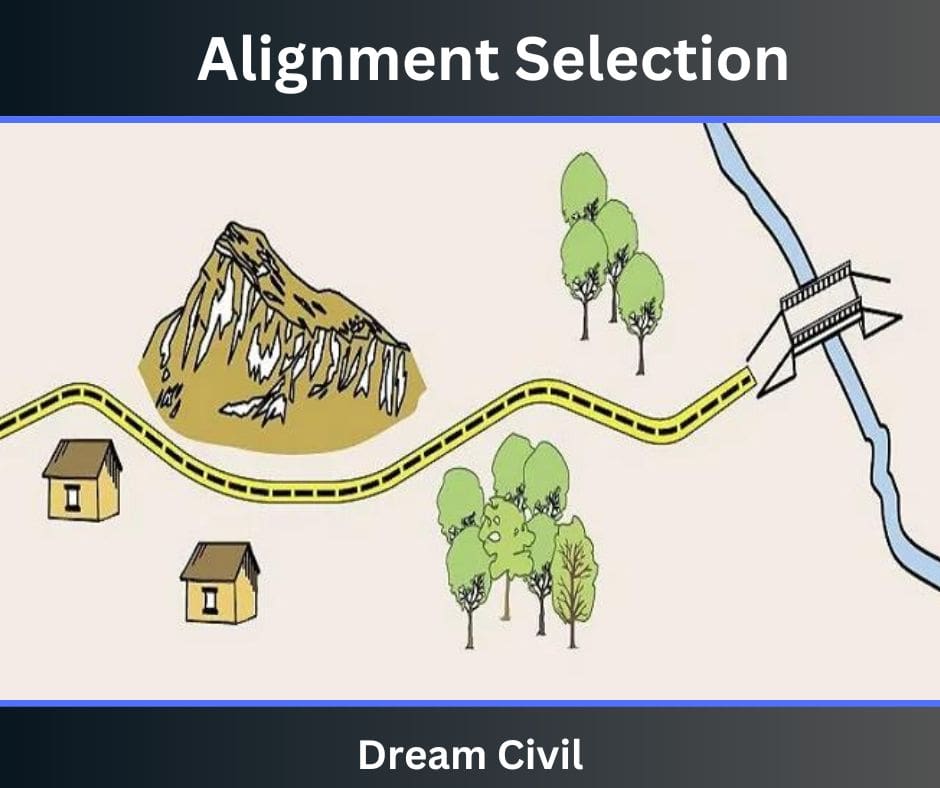

a. Alignment Selection

The alignment shows the path through which the road will pass. So, the selection of road alignment should be done such that it has less conflict, high soil strength & shorter length.

Road alignment is the key factor that directly influences construction speed and economy.

b. Cutting & Filling of Earth

Cutting and filling work is carried out to provide proper shape to the road.

During this process, if the side slope is unstabilized then retaining walls of wooden logs (or bamboo) are provided. In the absence of wooden logs; locally available stones are used.

c. Preparation of Sub-grade

Sub-grade preparation involves the process of compaction of the soil to increase strength, stability, and bearing capacity.

Compaction of subgrade should be done with the assistance of water.

Road strength is determined by subgrade. So, the subgrade should be compacted multiple times (according to the type of soil).

d. Preparation of Pavement

Above the subgrade, a layer of material is provided which acts as both base and surface course.

f. Drying

The road is allowed to dry naturally for 1 to 3 days and then opened to traffic.

4. Materials Required

a. Crushed Stone

b. Sand

c. Fines ( Silt or clay )

5. Required Equipment for Gravel Road construction

a. Bulldozers

b. Excavators

c. loader

d. Grader

e. Compactor

f. Dump truck

g. Water Tanker

h. Low-bed

6. Considerations in Gravel Road

1. The road shall be constructed on a balanced approach following the mass curve.

2. The road shall be constructed in stages.

3. Local materials shall be used.

4. Local manpower should be utilized.

5. Planning shall be done in a decentralized manner.

6. Bio-engineering shall be practiced for slope stability (instead of a costlier structure).

7. Cross slope of the road shall be towards the outside. so, as to avoid the side-drain.

8. In the case of natural water resources; a causeway shall be preferred instead of bridges, culverts, or other costlier construction.

9. The garbage wall and wooden log wall shall be preferred instead of the retaining wall.

7. Advantages of Gravel Roads

The advantages of Gravel roads are as follows:

a. Cheap to construct.

b. Local manpower and material are utilized.

c. It helps to mobilize rural materials.

d. It is more environment-friendly.

e. Maintenance cost is low

8. Disadvantages of Gravel Roads

The disadvantages of gravel roads are as follows:

a. Not suitable for heavy traffic.

b. The requirement of maintenance after heavy rainfall.

c. Low comfort & high vehicle operation cost.

d. High chances of Accidents.

3. References1. Content Filter & Authenticity Checking Team, Dream Civil International (Our team checks every content & detail to maintain quality.) |

Read More: Low-Cost Road