Table of Contents

Surveying is an important branch of civil engineering and is the first step of any type of construction. An important type of such surveying is chain surveying.

1. Introduction

Chain surveying is the surveying in which the measurements are taken in the field with the help of a chain and the calculations, as well as plotting, are done in the office.

The measurements taken in chain surveying are only linear. Angular measurements are not taken. This surveying offers fairly accurate results and is highly desirable for the survey of small areas.

2. Suitability of Chain Surveying

Chain surveying is most desirable in the following cases:

1. Area to be surveyed is fairly small.

2. The ground has fewer and simple details.

3. The ground is fairly leveled.

4. The area to be surveyed is relatively open.

3. Un-suitability of Chain Surveying

Chain surveying is not desirable in the following cases:

1. When the area to be surveyed is larger.

2. Presence of undulating areas.

3. Requirement of too many details.

4. Presence of too many obstacles.

4. Principle of Chain Surveying

The main principle of chain surveying is triangulation. With due regard to this, the entire area to be surveyed is divided into several suitable triangles.

Thus, a network of triangles is formed. As far as possible, the triangles must be such that no angle of the triangles is less than 30 degrees and not greater than 120 degrees.

Preferably, equilateral triangles must be formed. Hence, by measuring the sides of the triangle and the sequence; the plotting and preparation of the plan are accomplished.

5. Instruments Used in Chain Surveying

Some of the main instruments that are used in chain surveying are:

1. Chain

2. Tape

3. Ranging Rods

4. Arrows

5. Pegs

6.Cross Staffs

6. Basic Terms Used in Chain Surveying

Some of the terms that are commonly used in chain surveying are described in

short below:

1. Main Stations:

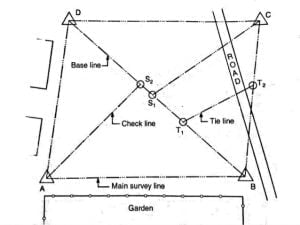

Main stations refer to the points at the end of the main survey lines forming the skeletal system. In other words, the main stations are the endpoints of the main survey lines that mark the boundary of the surveying area. In the figure below, A, B, C, and D represent the main stations.

2. Tie or Subsidiary Stations:

These are the intermediate stations that are specified in the main survey lines for determining the interior details. Some examples of such interior details include fences, hedges, etc. T 1 and T 2 represent the tie stations in the figure below.

3. Base Line:

The baseline is the main and longest survey line. It is the line concerning which all other measurements are taken for detailing of work. It usually runs from the center of the field (i.e. diagonally).

4. Chain Lines:

Chain lines are also commonly known as the main survey lines. These are the lines that join any two main stations.

5. Tie lines:

Tie lines are also commonly referred to as subsidiary lines. These are the lines that run between the subsidiary stations. Such lines help to check the accuracy of interior details.

6. Check lines:

These are also known as proof-lines. They are used to check the accuracy of the framework. The length of the check line measured on the ground must be consistent with its length on the plan.

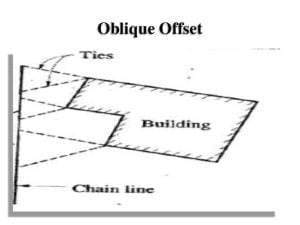

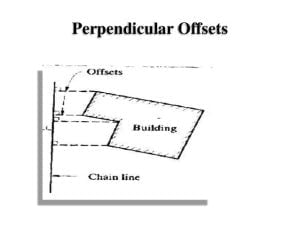

7. Offsets:

Offsets refer to the lateral measurements that are taken from the baseline. The main purpose of offsets is to locate the position of various objects concerning the baseline. Two types of offsets are generally used i.e. perpendicular offsets and oblique offsets.

7. Types of Chain Used in Chain Surveying

| Chain Name | Length | Links |

| Metric Chain | 20m 30m | 100 150 |

| Gunter’s Chain | 66′ | 100 |

| Engineer’s Chain | 100′ | 100 |

| Revenue Chain | 33′ | 16 |

8. The procedure of Chain Surveying

The procedure of chain surveying involves the following series of steps:

1. The initial step of chain surveying is reconnaissance. It involves the preliminary inspection of the area to be surveyed. A rough sketch or index map is prepared after inspection. . The whole area is divided into triangles.

2. After a reconnaissance of the area is completed, the stations are fixed. The fixing or marking of the stations can be accomplished by using one of the following methods:

a. Driving pegs.

b. Fixing ranging rods.

c. Marking cross marks on the relatively hard surface of the ground.

d. Digging and fixing of stones.

3. The main lines are selected then ranging rods are placed at the stations and chaining is initiated.

4. Measurement of chainage is done and offsets are taken.

5. The observations are duly recorded in the field book.

9. Factors To Be Considered During Survey Station Selection

The following points must be considered during the selection of survey stations:

1. The main lines must run through the leveled ground as far as possible.

2. A particular station must be visible from at least two or more stations.

3. The triangles must be properly defined with no angle less than 30 degrees.

4. The triangulation must be done such that survey lines are as few as possible.

5. Survey stations must be selected such that there is no difficulty in chaining or ranging.

6. The sides of the larger triangles must pass close to the boundary line.

7. Frequent passing through roads and trespassing must be avoided.

10. Advantages of Chain Surveying

Some of the advantages of chain surveying can be listed as follows:

1. Chain surveying is the simplest method of surveying. It is relatively simple to conduct.

2. It does not require any costly equipment and tools.

3. It is desirable for preparing the plan of small areas with a fair degree of accuracy.

4. Computations and plotting are also simple.

11. Disadvantages of Chain Surveying

Some of the disadvantages of chain surveying can be listed as follows:

1. Chain surveying is not suitable for large areas. As chaining of large areas becomes tedious.

2. It is relatively difficult to be carried out in crowded areas or bushy areas.

3. It is not suitable for areas with undulations where chaining is difficult and prone to errors.

4. The results obtained may not always give accurate results.

12. Errors in Chain Surveying

There are 3 major errors in chain surveying. They are:

a. Personal Errors

b. Instrumental Errors

c. Natural Errors

a. Personal Errors

Those errors that arise due to personal fault or negligencies of the surveyor are personal errors. These errors are serious and cannot be detected easily. Proper precautions should be taken to minimize or avoid such errors.

Some personal errors are:

a. Wrong recording

b. Wrong reading

c. Bad ranging

d. Improper plumbing

e. Reading from the wrong end of the chain, etc

b. Instrumental Errors

Those errors that arise due to defective instruments are instrumental errors. The erroneous length of the chain is an example of instrumental error.

c. Natural Errors

Those errors that are occurred due to natural factors are natural errors.

While taking readings in hot weather; the length of tape/chain may be increased for short period due to temperature that results in an error in surveying. It is the best example of natural error.

| For plane table surveying: Plane Table Survey |