Table of Contents

Water from any source may contain various suspended, colloidal and dissolved impurities which may be harmful or useful for drinking purposes.

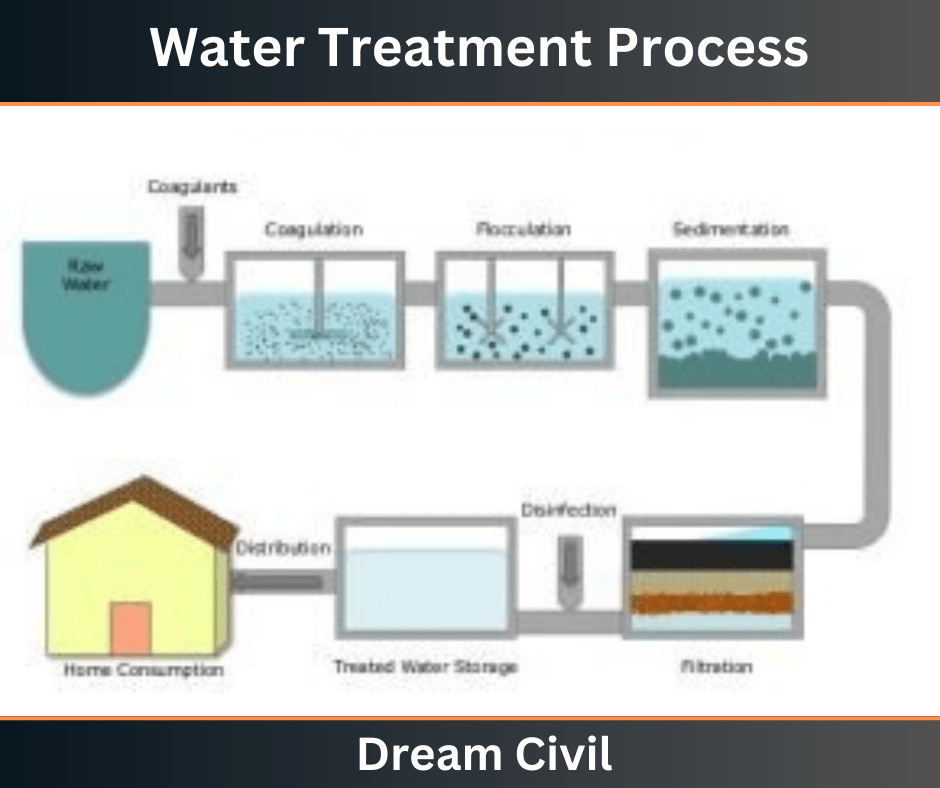

The process of removal of undesirable matters and pathogens from water is called the water treatment process.

The degree of treatment depends upon the quality of water desired or required.

There are various impurities having sizes as :

1. Suspended Impurities – a size larger than 10⁻³ mm

2. Colloidal Impurities – a size between 10⁻³ mm to 10⁻⁶ mm

3. Dissolved Impurities – a size smaller than 10⁻⁶ mm

1. Objectives of the Water Treatment Process

Some of the main objectives of the water treatment process are:

1. To reduce the impurities to a certain level that does not cause harm to human health.

2. To reduce the objectionable color, odor, turbidity, and hardness.

3. To make water safe for drinking.

4. To eliminate the corrosive nature of water affecting the pipe.

5. To make it suitable for a wide variety of industrial purposes such as steam generation, drying, etc.

2. Methods Of The Water Treatment Process

The water treatment process includes many operations like screening, aeration and sedimentation, sedimentation with coagulation, softening, filtration, disinfection, etc.

The water treatment process generally adopted depends upon the quality of raw water and the quality of water derived.

Methods of the water treatment process are explained below.

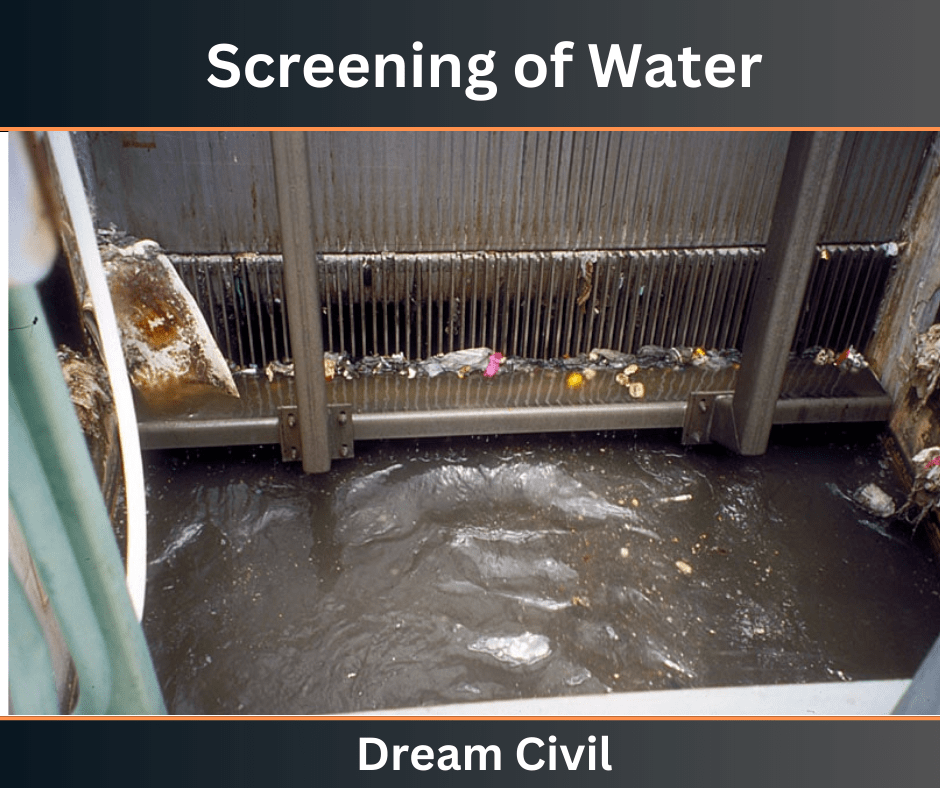

a. Screening

When water derived from the surface contain large suspended as well as floating matters which may be sticks, branches, leaves, etc; the screens are fixed in the intake works or at the entrance of the treatment plant to remove the suspended as well as floating matters like branches, leaves and sticks.

1.1 Purpose of screening

1. To remove large suspended as well as floating matter such as leaves, branches, dead animals, etc.

2. To work as a protective device for successive treatment.

3. To increase the efficiency of the successive.

1.2 Types of Screen

a. Bar Screen

The bar screen is also called the coarse screen.

They have a wider opening and are placed in front of the fine screen to remove large, floating, and suspended materials.

b. Fine Screen

The fine screen is used to remove smaller, floating, and suspending matter of size smaller than removed by the coarse screen.

b. Sedimentation

The process of the removal of suspended particles by gravitational settling is called sedimentation.

The water after screening may contain various suspended impurities like silt and clay particles. So to remove such particles sedimentation is done.

The particles whose specific gravity is greater than that of water gets settles down under the action of gravity.

Sedimentation tanks are designed to reduce the velocity of the flow of water so that the suspended particles get settled under the action of gravity.

Sedimentation can be achieved in two ways.

2.1. Plain Sedimentation

When the suspended particles are separated under the action of gravity only, it is called plain sedimentation.

2.2. Sedimentation with coagalities

Fine suspended particles and colloidal impurities are not removed by plain sedimentation. Particles of sizes 0.006 mm required 10 hours to settle in plain sedimentation.

Therefore we need certain chemicals to add in the water to remove such impurities which are not removed by plain sedimentation. These chemicals are known as coagulants and the process is called sedimentation with coagulation.

Examples of coagulants are (Al₂SO₄)₃, AlSO₄, odium aluminate, etc.

c. Aeration

It is the process of bringing water to contact with atmospheric air that contains oxygen.

Aeration is one of the important operations for making water healthy and pure.

3.1 Purpose of Aeration

1. To remove taste and odor by gases due to organic decomposition.

2. To increase the dissolved oxygen.

3. To remove hydrogen sulphide that causes odor.

4. To decrease carbon dioxide in water.

5. To kill the bacteria to some extent.

3.2 Methods of Aeration

Aeration is done by following the main types of Aerators:

1. Freefall aerators

i. Cascade aerators

ii. Inclined aerators

iii. Flat tray aerators

iv. Gravel bed aerators

2. Spray aerators

3. Air diffuser aerators

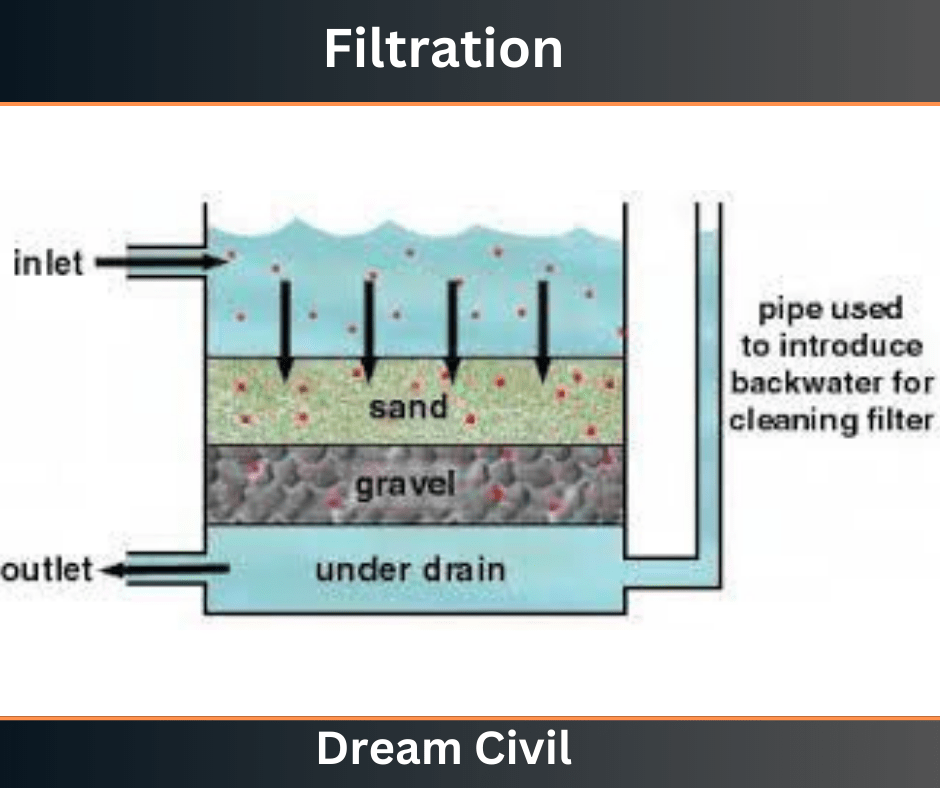

d. Filtration

Sedimentation and sedimentation with coagulation remove a large portion of suspended as well as colloidal particles which have specific gravity more than water.

Some particles have a specific gravity less than or equal to water which cannot be settled by the process of sedimentation.

For removing such particles and bacteria, odor, and taste; another operation is needed.

The process of passing water through beds of sand or gravel is known as filtration.

It consists of a bed of sand supported on gravel.

4.1 Types of Filter

a. Slow Sand Filter

These are the initial type of filters introduced in 1829 in England.

The rate of filtration through a slow sand filter is very slow.

The rate of filtration is 100 to 200 liters per sq. m per hour.

b. Rapid Sand Filter

The rapid sand filter is mostly used for treatment works in municipalities.

The rate of filtration work is 3000 to 6000 liters per square meter per hour.

c. Pressure Filter

In this filter, water passes through the sand bed under pressure.

This filter is used for industrial plants.

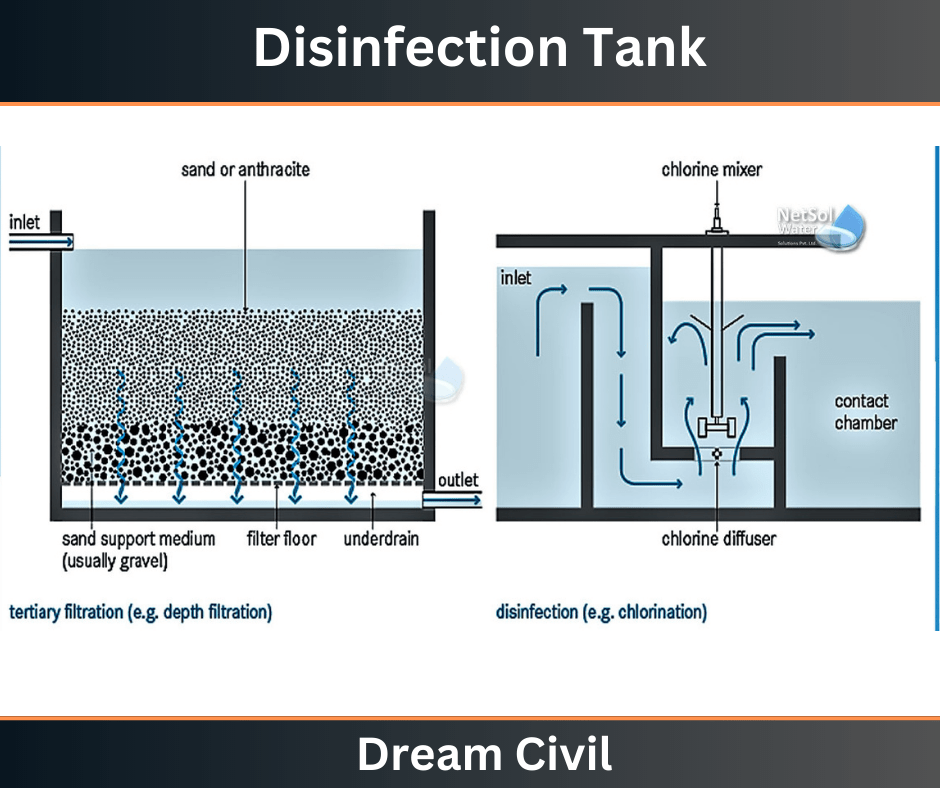

e. Disinfection

A slow sand filter can remove up to 99% of pathogens.

However, this percentage is less in the rapid sand filter.

So to neutralize the effects of remaining organisms; the water is passed through the disinfection process.

The killing of harmful bacteria with the help of chemicals or substances is called disinfection and the chemical used are called disinfectants.

Examples of disinfectants are hydrogen peroxide, formaldehyde, sodium hypochlorite phenol, etc.

(Note: Sterilization is the process of elimination of organisms whether they are useful or harmful.)

5.1 Purpose of Disinfection

1. To kill pathogenic bacteria and organisms present in water.

2. To make people safe from water-borne diseases.

3. To reduce the chance of epidemics.

5.2 Requirement of a Good Disinfectant

1. The disinfection should be able to remove all pathogenic in a short time.

2. It should be cheap and easily available.

3. The water should not be toxic and objectionable after the addition of disinfectant.

5.3 Methods of Disinfection

5.3.1. Physical Method

1. Boiling

Boiling of water is an effective and safe practice for disinfection of pathogenic micro-organisms.

It is not feasible for community water supply due to the high energy requirement for boiling water.

2. Sun Light

Pathogenic organisms can be destroyed by solar radiation.

It has been found that if the water in a transparent bottle is exposed to full sunlight for about 7 hours, the water is completely disinfected.

5.3.2. Chemical Methods

Some of the chemical tests in the process of disinfection are:

1. Chlorination

2. Bromine treatment

3. Iodine treatment

4. Ozone treatment

5. Silver treatment

6. Potassium Permanganate treatment

Among them; chlorination is the most widely used method. So, we are explaining only chlorination.

Chlorination is the process of the addition of chlorine to kill the bacteria.

Chlorination is widely adopted in all developing countries for the treatment of water in the public water supply system.

3. Layout of the Water Treatment Plant

The following are the major consideration for the layout of a treatment plant:

1. The water treatment plant should be located near the distribution area to reduce contamination in distribution.

2. All the units are arranged in a way that a minimum area is required to reduce the cost of construction.

3. All the units of plants should be located in an order of sequence flow from one unit to another by gravity.

4. There should be the availability of sufficient areas for future expansion.

5. For operation and maintenance, staff should be provided with staff quarters near the treatment plant. So that the operator can watch plants easily.

4. References1. Content Filter & Authenticity Checking Team, Dream Civil International (Our team checks every content & detail to maintain quality. ) |

Read More: Water Distribution System