Table of Contents

1. Introduction

The tunnel can be defined as the underground passage that is constructed beneath the earth’s surface or water. It is an important civil engineering structure that is used extensively all over the world. It is used for roadways, railways, and even waterways. Several methods have been developed around the world for the construction of tunnels. One such method of tunnel construction is by using the tunnel boring machine i.e. bored tunnel method.

A tunnel Boring Machine is commonly referred to as TBM or Mole.

A tunnel boring machine can be defined as the machine primarily designed to excavate the tunnels with a circular cross-section that is designed in such a way that it is capable of boring anything from sandy soil to hard rocks.

There are mainly two types of tunnel boring machines that are mainly used.

A tunnel boring machine is the modern type of machine used for boring the tunnel. It is also used for microtunneling.

It can also be used for the excavation of non-circular tunnels, u-shaped tunnels, horseshoe tunnels, rectangular tunnels as well as square tunnels.

The diameter of the tunnel that can be excavated can range from 1 meter to 17.6 meters.

Tunnel boring machine can be used as an alternative to the conventional drilling and blasting method of tunnel construction.

The machine is manufactured in such a way that only limited disturbance is caused to the surrounding soil layers and to ensure the excavated tunnel has a smooth wall. Hence, the cost of the tunnel lining can be reduced greatly.

TBMs are the most desirable method of tunnel construction for heavily urbanized areas.

Tunnel boring machines are capable of automatically excavating the tunnel thereby making the entire tunnelling process much easier.

2. Advantages of Tunnel Boring Machine

Some of the advantages of the tunnel boring machine can be listed as follows:

1. It offers a higher degree of precision and the entire operation can be completed within a short period.

2. It is suitable for the construction of tunnels in high traffic areas and urbanized areas.

3. It is designed to operate in various ground condition as it is capable of boring sand to hard rocks.

4. It can also be used for the tunnel construction even in difficult conditions such as below water table.

5. It offers greater structural stability and safety at the face as well as the work area.

6. It can be operated continuously.

7. It is capable of boring without causing significant disturbance to the surrounding soil layers.

8. The operation of TBM is relatively consistent and less skilled.

9. It offers a better working environment compared to the conventional drilling and blasting method.

10. The number of laborers required is also lesser.

3. Disadvantages of Tunnel Boring Machine

Some of the disadvantages of a tunnel boring machine can be listed as follows:

1. The main disadvantage of the tunnel boring machine is the upfront cost. This is because the high cost is required for the supporting accessories and equipment such as conveyor belts, slurry separating plant, slurry pipelines, drill bits, TBM cutters etc.

2. TBMs offer limited flexibility in terms of geological extremities.

3. High backup systems are required for TBMs.

4. TBMs offer only fixed circular geometry and tunnel diameter.

5. The mobilization time required is higher.

6. The machine is very heavy and transportation is difficult.

4. Types of Tunnel Boring Machine

The tunnel boring machine can be classified into the following types:

a. Hard Rock Tunnel Boring Machine

As the name itself implies, the hard rock tunnel boring machine is used to excavate the tunnels in hard rock.

They are provided with disc cutters mounted in the cutter head to excavate the rocks.

These TBMs commonly include shielded tunnel boring machines and open-type tunnel boring machines.

The disc cutters that are provided in such TBMs are designed in such a way that they create compressive stress fractures in the rock which in turn causes it to chip away from the face of the tunnel.

Once the excavation is completed, the excavated rock or the muck is transferred through the openings provided in the cutter head to the belt conveyor for removal from the tunnel.

In the open-type hard rock TBM, the shield is not provided and the area behind the cutter head is kept open to provide the support to the rock.

TBMs make use of the gripper system that pushes against the walls of the tunnel for advancing the machine. Then, the TBM will push forward off the grippers thereby gaining the thrust.

The rear legs of the machine are then lowered and thus the grippers and the propel cylinders retract. Hence, such retraction of the propel cylinders assures the rearrangement of the gripper assembly for the next boring cycle.

The shielded type hard rock TBMs can be used in the fractured rock.

The shielded type hard rock TBMs operate by erecting the concrete segments to provide support to the unstable tunnels behind the TBM.

In the case of stable ground, double shield TBMs can be employed.

The double shield TBM consists of two modes to grip the tunnel walls to advance.

The single shield-type TBM also function in the same way as the double shield-type TBM and are used only for the fractured rocks.

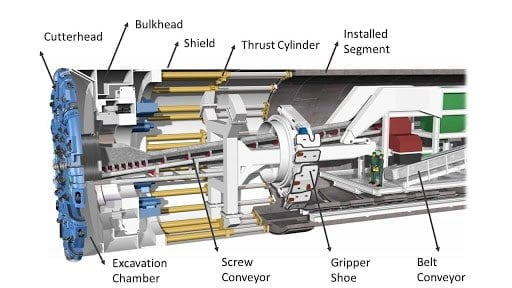

Figure: Hard Rock Tunnel Boring Machine

2. Soft Ground Tunnel Boring Machines

The soft ground tunnel boring machines are the type of TBMs that are used for the construction of tunnels in soft ground.

This type of TBM can be further grouped into three types namely Earth Pressure Balance Machines (EPB), Slurry Shield (SS) and open-face type.

These types of TBMs mostly use the thrusting action of the cylinders to advance by pushing off against concrete segments.

The cutter head is provided with an arrangement of tungsten carbide cutting bits, carbide disc cutters, drag picks and hard rock disc cutters.

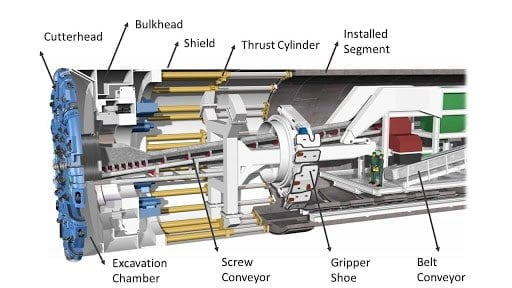

Figure: Soft Ground TBM

| Read More: Offsite Construction |

| Read More: Ranging in Surveying |