Table of Contents

1. Introduction

One of the most important properties of the soil is the grain properties. The grain properties of soils are the particle size, grain shape and mineralogical composition. Thus, to determine the particle or grain size of such soil, a procedure commonly referred to as sieve analysis is done.

Determination of the grain size is necessary for various civil engineering constructions since various other properties such as bulk density, permeability, physical stability etc are dependent on it.

In a general sense, Sieve Analysis can be understood as the test procedure to determine the particle size distribution.

Sieve analysis is defined as the procedure used to assess the particle size distribution of granular material by allowing the material to pass through a series of previously arranged progressively smaller mesh sizes and duly weighing the mass of particles retained on each sieve as a fraction of the whole mass.

In other words, it is the laboratory procedure of allowing the sample materials to pass and move horizontally or vertically through a set of standard sieves.

Sieve analysis is also commonly known as Gradation.

The process of sieve analysis is generally used for granular materials (both organic and inorganic) such as crushed rock, sands, clays, granite, feldspars etc.

The main advantage offered by this method is that it is a very simple and easy method. Depending upon the application, several methods of sieve analysis can be used.

2. Importance of Sieve Analysis

The primary objective of sieve analysis is to classify the soil particles based on their size of particles.

The main importance of sieve analysis in civil engineering can be listed as follows:

1. It is necessary for design purposes. The process of concrete mix design is greatly influenced by the size of coarse aggregates to be used.

2. It is necessary to predict the quality and performance of the soil sample.

3. The analysis of foundations of structures is also dependent on the particle size distribution of the soil.

4. Sieve analysis is necessary for determining the fineness modulus of aggregates.

5. Sieve analysis is also important in the design of pavements.

3. Uses of Sieve Analysis

Gradation is the main application of sieve analysis which distinguishes the various properties of soil mechanics, aggregates, etc. used for the construction of various structures.

4. Sieves for Sieve Analysis

Sieve is the chief apparatus required for conducting the sieve analysis.

Generally, a sieve may be understood as an apparatus similar to a utensil that essentially consists of a wire or plastic mesh held in a frame used for separating coarser particles from the finer particles.

Sieves commonly used can be classified into the following:

1. Perforated Plate Sieves:

These are the sieves under the ISO 3310-2.

Perforated plate sieves consist of nominal apertures ranging from 1 millimetre to 125 millimetres.

The apertures may be round or square.

The diameter of such a sieve ranges from 200 to 450 millimetres.

2. Woven Wire Mesh Sieves:

These are the sieves under the ISO 3310-1.

Woven wire mesh sieves consist of nominal apertures ranging from 20 micrometres to 3.5 millimetres.

The diameter of such a sieve ranges from 100 to 450 millimetres.

3. American Standard Sieves:

The American Standard sieves are the sieves under the ASTM E11 standards.

These sieves are also commonly known as ASTM Sieves.

The nominal aperture of such sieves ranges from 20 micrometres to 200 millimetres.

4. Indian Standard Sieves:

The Indian Standard sieves are the sieves under IS 383.

These sieves are also commonly known as IS Sieves.

5. Apparatus Required

1. Sieves of appropriate sizes.

2. Balance with an accuracy of 0.01 grams.

3. Sieve Shaker.

4. An oven.

6. Procedure

The procedure for sieve analysis involves the following series of steps:

1. A sample of about 500 grams is first taken.

2. The representative sample is dried in a ventilated oven.

3. In case the sample consists of lumped particles, the lumps must be crushed.

4. The sample is then weighed and its mass is duly recorded.

5. The sieves of different sizes are then taken and arranged in a particular order i.e. with the largest aperture size at the top and the smallest at the bottom. A pan is placed at the bottom to collect the samples.

6. The weighed sample is then poured into the top of the stack of sieves and the lid is put.

7. The stack of sieves is then stacked in the sieve shaker and the clamps are fixed.

8. The timer is set to 10 or 15 minutes and the sieve shaker is switched on.

9. Afterwards, the sample retained on each sieve is weighed.

10. The result is then calculated using the following formula:

% Retained = (W sieve /W total ) * 100%

Where,

W sieve = mass of aggregate in the sieve

W total = total mass of aggregate

% cumulative passing = 100% – % cumulative retained

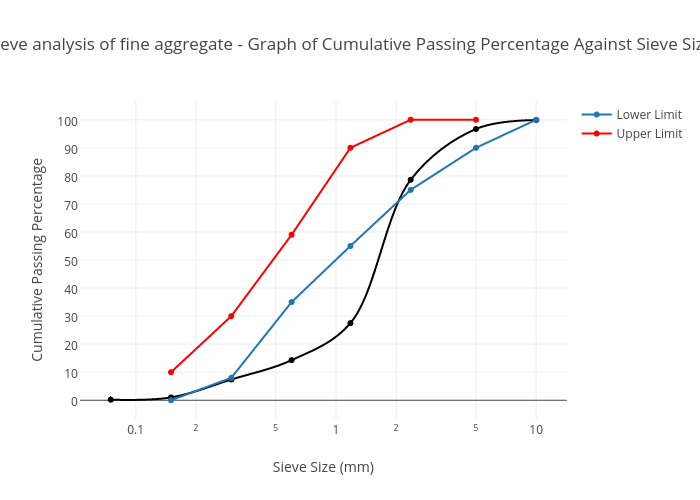

The values are then plotted on the graph with the sieve size on X-axis and the

cumulative % passing on the Y-axis.

7. Precautions in Sieve Analysis

a. During sieve analysis, sieve should be shaken in the rotation rather than translating linearly.

b. To sieve, the small mass should be used each time for better sieving.

8. Advantages of Sieve Analysis

a. It helps to determine the size of particles and fineness of aggregates.

b. The sieve analysis is crucial for any type of granular materials like sand, cement, crushed rocks, soil, coarse etc. to determine various physical properties.

c. It is easy to perform and the non-technical person also can perform this test.

9. Disadvantages of Sieve Analysis

a. Sieve analysis is not beneficial to take an accurate reading of 100 mesh finer materials.

c. Dispersing the wet particles while sieving is quite uneasy process.

| Read Also: Impact Test on Aggregates |