Table of Contents

1. What is LVL Beam?

✔ LVL beams (Laminated Veneer Lumber) are beams generated by engineered wood. They are assembled by bonding thin wood veneers, typically softwoods like pine, spruce, or fir, with sealants subjecting them to lofty heat and pressure.

| Property | Description |

|---|---|

| Composition | Multiple layers of thin wood assembled with adhesives |

| Common Uses | Headers, beams, rim board, edge-forming material |

| Strength | Stronger, straighter, and more uniform than milled lumber |

| Resistance | Less likely to warp, twist, bow, or shrink due to its composite nature |

| Manufacturing Location | Commonly produced in North America |

| Size Range | Varies but can be compatible with I-joist framing members for use as beams and headers |

| Key Technical Ratings | Elastic modulus: 12-14 GPa; Allowable bending stress: 19-21 MPa |

| Composition (General) | Approximately 97.54% wood, 2.41% phenol formaldehyde resin, 0.02% phenol-resorcinol-formaldehyde resin, 0.03% fillers |

| Caution | Not suitable for outdoor load-bearing use due to limitations with chemical treatments |

2. Technical Detail and Application of LVL Beam

| Technical Details of LVL Beams | |

| Modulus of Elasticity (MOE) | ✔ 1.6 to 2.0 million psi |

| Modulus of Rupture (MOR) | ✔ 3,500 to 7,000 psi |

| Shear Strength | ✔850 to 1625 psi |

| Bearing Strength | ✔ 500 to 1,500 psi |

| Applications of LVL Beams | |

| Beams and Headers | ✔ Residential and commercial construction, bridges, and heavy-duty structures. |

| Rim Joists and Floor Joists | ✔ Homes with wide spans or heavy loads. |

| Glue-Laminated Timber (Glulam) | ✔ Heavy-duty construction, bridges, stadiums, large structures. |

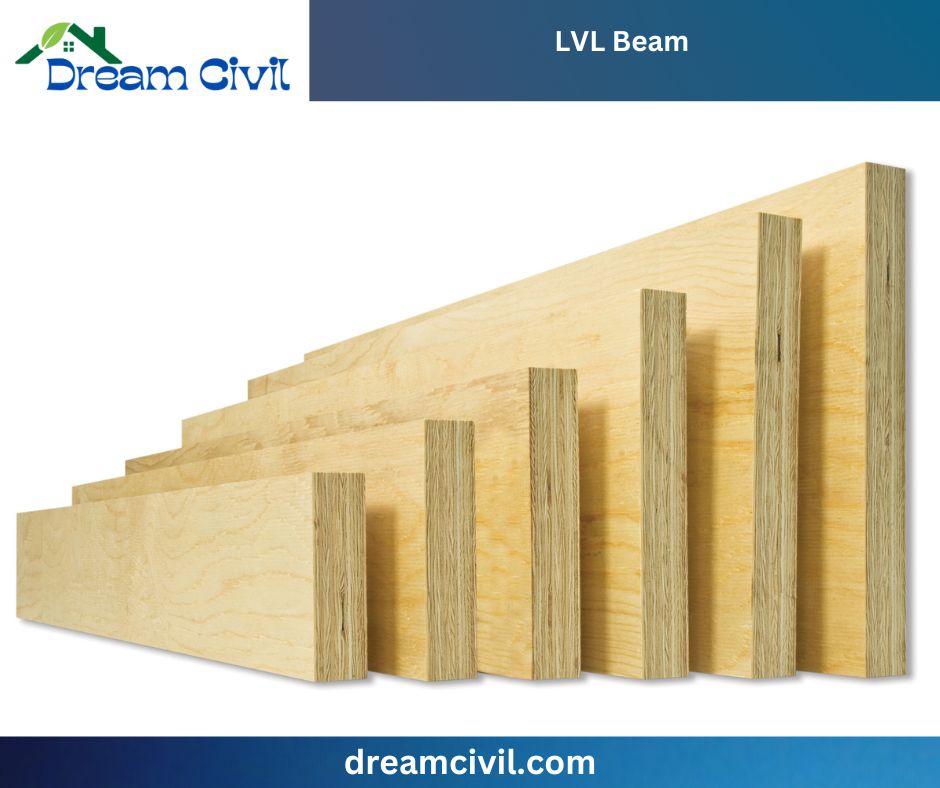

3. Laminated Veneer Lumber Beam Sizes (LVL Sizes):

✔ Manufacturers deliver various sizes for LVL beams, although the authoritative thicknesses typically range between 7/4 and 7/2 inches.

✔ LVL beams are typically available in lengths of 24, 28, 32, 36, 40, and 44 feet, with the prospect of superior orders up to 60 feet.

✔ The depths of LVL beams vary from 5.5 inches to 24 inches and are estimated in increments such as 29/4 inches, 37/4 inches, 19/2 inches, 45/4 inches, 95/8 inches, 14 inches, 16 inches, 18 inches, 75/4 inches, 20 inches, and 191/8 inches.

a. LVL Beam Thickness

✔ LVL beam standard thicknesses range from 7/4 inches to 7 inches.

✔ It comes in 1 plywood of thickness 7/4″, two plywood of 7/2″ thick, three plywood of 21/4″ wide, and four plywood of 7″ thick.

b. LVL Beam Length

✔ LVL beam lengths are typically available in 24, 28, 32, 36, 40, and 44 feet, with excellent rankings up to 60 Feet.

✔ The LVL Beams found in the market are 4-foot increments. It can be acclimated according to user choice. More than 60 Feet in size is severe to enrapture and handle.

c. LVL beam depth

✔ The depth of an LVL beam is 11/2 inches (140 mm), 29/4 inches (184 mm), 37/4 inches (235 mm), 19/2 inches (241 mm), 45/4 inches (286 mm), 95/8 inches (302 mm), 14 inches (356 mm), 16 inches (406 mm), 18 inches (457 mm), 175/4 inches (476 mm), 20 inches (508 mm) and 191/8 inches (606 mm).

4. What is the range of LVL Beams Cost?

✔ The cost of Laminated Veneer Lumber (LVL) beams usually plunges between $3 to $12 per linear foot for the materials alone.

✔ Opting for induction could inflate the cost to around $50 to $200 per foot, resulting in a total installation expenditure of roughly $800 to $2,500.

5. How Much Does it Cost to Install LVL Beams?

✔ An LVL Laminated veneer lumber or Engineered beam costs $3 to $12 per foot for just the materials.

✔ Install a Laminated veneer lumber beam for residential construction costs $50 to $200 per foot or around $800 and $2,500.

| LVL Beam Size | Cost |

| 24-ft | $72 to $288 |

| 30 ft | $90 to $360 |

| 20 ft | $60 to $240 |

| 22 ft | $66 to $264 |

| 25 ft | $75 to $300 |

| 26 ft | $78 to $312 |

| 28 ft | $84 to $336 |

| 18 ft | $54 to $216 |

| 16 ft | $48 to $192 |

| 14 ft | $42 to $168 |

| 12 ft | $36 to $144 |

6. What are the advantages and disadvantages of LVL Beam?

| Advantages | Disadvantages |

| High strength-to-weight ratio | Costlier compared to traditional lumber |

| Uniform quality | It may be more difficult to work with than traditional lumber. |

| Straight | Not as aesthetically pleasing as traditional lumber |

| Resistant to warping and twisting |

7. Qualities of LVL:

✔ Laminated veneer lumber stands similar in appearance to plywood, although in plywood, the veneers swap direction while stacking, and in LVL, the surfaces all stack in the identical order.

✔ In LVL, the direction of the wood grain is invariably parallel to the length of the billet.

✔ Stacking these veneers into a complete board, called a billet, makes a single part of LVL convey a common direction of the wood grain.

✔ The manufacturer generally rates LVL for elastic modulus and allowable bending stress.

✔ Standard elastic moduli are 12 GPa (1,700,000 psi), 13 GPa (1,900,000 psi), 14 GPa (2,000,000 psi), and common permissible bending stress values are 19 MPa (2,800 psi), and 21 MPa (3,000 psi).

✔ Although the creation of LVL is usually proprietary, and thus its make-up is primarily dependent on particular manufacturers, in general, one cubic meter of North American Lumber is composed of 97.54% wood, 2.41% phenol formaldehyde resin, 0.02% phenol-resorcinol-formaldehyde resin, and 0.03% fillers

| Component | Percentage |

|---|---|

| Wood | 97.54% |

| Phenol formaldehyde resin | 2.41% |

| Phenol-resorcinol-formaldehyde resin | 0.02% |

| Fillers | 0.03% |

8. Manufacturing of LVL Beams:

✔ LVL is usually produced in North America by companies preparing I-joists. LVL is prepared to sizes consistent with the depth of I-joist framing members for benefit as beams and headers.

✔ Further, some factories cut LVL into needed dimensions for usage as chord members on I-joists.

✔ In 2012, North American LVL factories made more than 1.2 million cubic meters (43.4 million cubic feet) of LVL in 18 various facilities, and in 2013, the production grew by more than 14%.

✔ It is not concurrent that LVL mills are usually co-located with I-joist manufacturing facilities as many builders employ a variety of I-joists and LVL in floor and roof assemblies.

9. Interesting Point to be Noted:

| Composition | ✔ It was engineered by bonding thin wood veneers from softwood species (e.g., pine, spruce, fir) with robust adhesives (e.g., phenol-formaldehyde, melamine-formaldehyde resin). |

| Manufacturing Process | ✔ Veneers are stacked, glued with grains oriented in the same direction, and cured under high heat and pressure for stability and solidity. |

| Size and Dimensions | ✔ Various sizes and dimensions are available for load-bearing requirements and span lengths. |

| Grade | ✔ Structural grade (e.g., “LVL-1” or “LVL-2”) is assigned based on factors like veneer quality, adhesive type, and manufacturing processes. |

| Span Capacity | ✔ They are designed and tested to support specific loads over defined spans, with span tables and load-span charts for beam selection. |

| Flanges and Core | ✔ It comprises a core and flanges; thick and thin flanges enhance stiffness and load-carrying capacity. |

| Fire Resistance | ✔ Fire resistance may vary based on the adhesive used during manufacturing. |

| Installation | ✔ Proper installation guidelines provided by manufacturers should be followed, including appropriate fastening methods, support spacing, and attachment hardware. |

| Applications | ✔ They are used in residential, commercial, and industrial construction for floor and roof framing, wall framing, headers, beams for doors and windows, and other load-bearing structural components. |

| Sustainability | ✔ Environmentally sustainable, optimizing wood resource use from responsibly managed forests and more diminutive, fast-growing trees. |

| Read Also: WPC Board |

| Verified By: Er. Bipana Kshetri Puri |