Table of Contents

In this article, we will discuss the Limit state method Vs Working stress method.

1. Limit State Method Vs Working Stress Method

The design of reinforced concrete structural members involves the knowledge of loads, material properties and factors of safety. The working stress method is referred to as Deterministic because it is presumed that loads, permissible stresses and factors of safety are known accurately. In physical situations, however, these Parameters are not always known and the analysis must then be based on predictions.

The prediction of such parameters is normally based on experience or on field data. The design of a structural member depends on how closely an actual situation is predicted, Parameters that involve the element of prediction are referred to as Nondeterministic and there is no guarantee that they will actually occur. This forms the basis of Limit state design.

bIn the limit state design method these parameters are determined based on observations taken over a period of time. These parameters will thus be influenced by chance or random effect not just at a single instant but throughout the entire period of time or the sequence of time that is being considered Such a process is referred to as a Stochastic process.

In a rough sense, a stochastic process is a phenomenon that varies to some degree unpredictably as time goes on It is also referred to as a Random process.

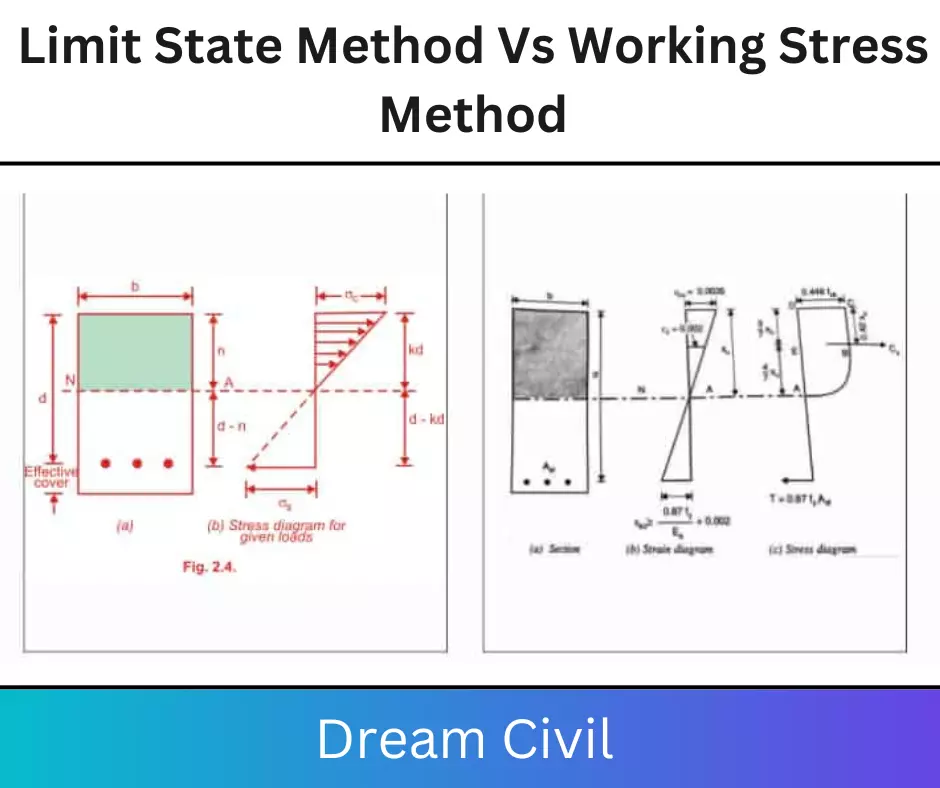

In the limit state design procedure stresses in an element are obtained from the design loads (including load factors) and compared with design strengths (including safety factors). In the working stress design method the stresses in an element are obtained from working loads and compared with permissible stresses.

The main distinction between the two methods lies65 in the fact that in the former, a member is considered in its limit state, whereas in the latter in its working state. This requires more stringent conditions that loading conditions leading to collapse as well as partial safety factors are determined very carefully and accurately in the Limit state design.

Structural members designed on the basis of permissible stress using a factor of safety regardless of different working conditions and load combinations actually had different safety margins.

The limit state method is based on physical parameters. The partial factors are based on statistical and probabilistic grounds and can be controlled. Thus, it is a more scientific approach to the design of reinforced concrete.

Limit State Method Vs Working Stress Method

| Sl. No. | Working Stress Method | Limit State Method |

| 1. | This method is based on the elastic theory which assumes that concrete and steel are elastic and the stress-strain curve is linear for both. | This method is based on the actual stress-strain curves of steel and concrete. For concrete the stress-strain curve is non-linear. |

| 2. | In this method, the factor of safety is applied to the yield stresses to get permissible stresses. | In this method, partial safety factors are applied to get design values of stresses. |

| 3. | No factor of safety is used for loads. | Design loads are obtained by multiplying partial safety factors of load to the working loads. |

| 4. | The exact margin of safety is not known. | The exact margin of safety is known. |

| 5. | This method gives thicker, sections, so less economical. | This method is more economical as it gives thinner sections. |

| 6. | This method assumes that the actual loads, permissible stresses and factors of safety are known. So it is called a deterministic method. | This method is based on the probabilistic approach which depends upon the actual data or experience, hence it is called a non-deterministic method. |

Read Also: Slump Test