Table of Contents

A damp proof course is commonly abbreviated as the DPC.

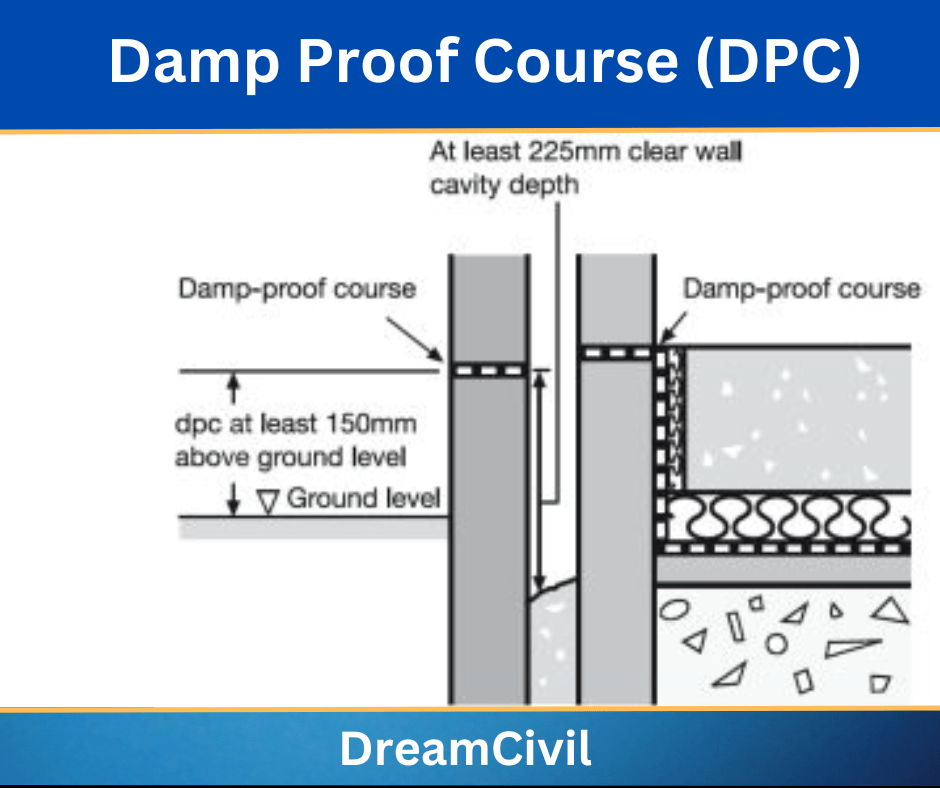

DPC is a barrier or obstruction that is primarily designed to prevent the moisture rising by the capillary action.

The capillary action through which the moisture rises is known as rising damp.

In other words, a damp proof course can be defined as the layer of material that is used to prevent the penetration or passage of moisture inside the structure through the floors, walls or roofs.

It is commonly applied at the basement level of the structure and thus prevents the passage of moisture through the floors and the walls.

1. Purpose of Damp Proof Course (DPC)

The major purposes of the damp proof course can be listed as follows:

a. To prevent the movement of moisture in the structure.

b. To prevent the breeding of mosquitoes, growth of termites and other unhealthy conditions that may arise due to dampness.

c. To prevent the development of unpleasant patches on the walls of the building.

d. To protect the painted surfaces from dampness.

e. To prevent the softening as well as crumbling of the plasters.

f. To prevent the deterioration of timber fittings such as doors and windows by warping due to the contact with dampness for a subsequent period.

g. To protect the floors from the detrimental effect of moisture movement such as reduction of adhesion, loosening of flooring etc.

h. To prevent the pipes and fittings from corrosion by the ingress of moisture.

2. Desirable Properties of Materials for Damp Proof Course (DPC)

The desirable properties of the materials used for the damp proof course can be listed as follows:

a. The material used for the damp proof course must be impervious i.e. it must prevent the passage of moisture through it.

b. The material must be strong as well as durable. It must be strong enough to resist both the imposed live loads and dead loads without failure.

c. It must be dimensionally stable.

d. It must be free from harmful deliquescent salts such as chlorides, nitrates and sulphates.

Read More: 26 Types of Concrete

3. Materials Used for Damp Proof Course (DPC)

Various types of materials are available for the construction of the damp-proof course.

These materials are generally selected based on the type of structural element of the building and the type of damp proofing required.

The most common types of materials used for the damp proof course can be listed as follows:

a. Flexible Materials for DPC

These are the materials that do not deform their shape and do not crack when subjected to loading.

Some of the flexible materials that are used for the damp proof course can be listed as follows:

a. Mastic Asphalt/ Bitumen Asphalt

The mastic asphalt mainly consists of bitumen that is mixed with the fine sand in the hot state to form an impervious mass.

When the mixture is hot, the consistency is such that it allows the mixture to spread evenly to a depth of about 2.5cm to 5cm.

Upon cooling, the mixture sets.

However, special care must be taken while laying the mastic asphalt as the damp proof course.

b. Hot Laid Bitumen

The hot-laid bitumen is mostly used on a bedding of cement concrete or mortar.

It is usually laid in two consecutive layers at the rate of 1.75 kg/m² of the area.

c. Bitumen Felts (Sheets)

The bitumen felts consist of a 6mm thick sheet of bitumen prepared in rolls and having a width equal to that of a brick wall.

d. Metal Sheets

Metal Sheets are used throughout the thickness of the walls to prevent dampness.

Mostly, metal sheets of aluminium, lead and copper are used for such purposes.

These sheets are coated with asphalt such that the thickness of the sheet is equal to or greater than 3mm.

The metal sheets of lead must be laid over the lime mortar instead of cement mortar because the chemical reaction between cement and lead may occur.

Metal sheets are highly effective in preventing dampness but are relatively expensive.

b. Rigid Materials for DPC

The rigid materials are not capable of withstanding the traverse stresses and cracks when subjected to extreme loading. Some of the rigid materials used in DPC are:

a. Rich Concrete

Rich Concrete is the most commonly used material in DPC.

Usually, rich concrete in the proportion 1:2:4 that is painted with two relative coats of hot bitumen is used for the horizontal damp proof course.

It is suitable for the portions of the building or structure that are not subjected to excessive damping. It prevents the ingress of moisture by the capillary action.

b. Mortar

Mortar is extensively used for vertical damp-proof courses.

Usually, a 2 cm thick rich cement layer and sand mortar(1:3) are applied on the inner surface of the external wall.

After laying the mortar, the surface is painted with hot bitumen in two coats.

c. Bricks

Bricks are used when effective damp proofing is required on a comparatively low budget.

Mostly, dense bricks and over-burnt bricks are used for this purpose.

The bricks are laid in rich cement and sand mortar of a ratio of 1:3.

It is used for the DPC in the cheap type of construction.

d. Stones and Slates

Two layers of stones are laid in lime, cement and sand mortar (1 lime :1 cement: 6 sand) which acts as DPC.

In some cases, the slate and the stone slabs can also be laid in cement sand mortar.

It is mostly used where quality stones are found easily at a cheap rate.

Read Also: Curing of Concrete

4. Factors to be Considered During the Selection of Materials for DPC

a. For DPC above ground level, it is desirable to use cement concrete of a ratio of 1:2:4 (M15).

In the case of a damp and humid atmosphere, a richer mix of concrete must be used.

Various water-resistant materials such as Pudlo, Impermo, and Waterlock may be added to the concrete mix to make it denser.

b. For the DPC of floors and roofs, flexible materials such as mastic asphalt, bitumen felts, plastic sheets etc must be used.

It must be ensured that such materials bond well with the surface.

c. For DPC of cavity walls, flexible materials such as bitumen strips, lead strips etc are desirable.

5. Factors to be considered during the Construction of a DPC

Some of the factors that must be considered during the construction of the damp proof course are as follows:

a. Before the damp proof course is laid, the mortar upon which it is to be laid must be made level, even and free from any sort of projections.

This is done to ensure that no damage is done to the damp proof course due to the unevenness of the base.

b. In the case of a horizontal damp proof course, it must be continued up to the vertical face.

A cement concrete fillet which is about 75 mm in radius must be provided at the junction before the treatment.

c. Each of the damp proof courses must be placed in correct relation to other consecutive courses so that a complete barrier is constructed to check the movement of water from walls, roofs or floors of the building.

d. The damp proof course must be laid such that it covers the entire thickness of the walls by excluding the rendering.

Read More: Grades of Concrete

6. Methods of Damp Proof Course (DPC)

The methods that are mostly adopted for dampness prevention can be explained as follows:

a. Surface Treatment

Surface treatment includes the method of laying a water-repellant layer or water-resistant substance on the surface through which dampness is likely to occur.

It is the most common method of damp proofing when moisture or dampness occurs superficially.

Usually, for surfaces exposed to rainwater, water-resistant substances such as calcium, aluminium and stearates are used.

In the case of the pointing and the plastering of the exposed surfaces, waterproofing agents such as potassium silicate, sodium silicate, zinc sulphates, aluminium sulphates, barium hydroxide and magnesium sulphate are commonly used.

b. Pressure Grouting

Pressure grouting is the method of damp proofing in which pressure is applied for filling up the cracks and voids in the structure by cement grout thereby preventing the ingress of moisture.

This method is most commonly adopted for the DPC of foundations.

c. Guniting

Guniting is the method of damp proofing in which a layer of rich cement mortar is deposited on the exposed surface of walls and pipes utilizing pressure.

Usually, cement sand mortar in the ratio 1:3 is used for this purpose.

The surface where the damp-proofing is to be done is first thoroughly cleaned then the mortar is shot on the cleaned surface with a cement gun.

The pressure is applied at the rate of 2 kg/cm² to 3 kg/cm².

During the process, the nozzle of the gun is kept at a distance of about 75 to 90 cm from the wall.

Finally, the mortar is allowed to be cured for about 10 days.

d. Integral Treatment

It is the process of adding certain additives to the mortar (or concrete) during the mixing process to make the mixture impermeable.

This is accomplished by various chemical actions and mechanical effects of the additives on the concrete or mortar mix.

Usually, the compounds of chalk, fuller’s earth, talc, etc are used as additives for filling the voids by the principle of mechanical action.

On the other hand, the compounds such as aluminium sulphates, alkaline silicates, calcium chlorides, zinc sulphates, calcium, aluminium or ammonium chlorides, iron fillings, etc fill up the voids by chemical reaction with the concrete to produce water-resistant surfaces.

If 5% soap is added to the water to be used for preparing mortar the pores get closed and the coating of water-repellent substance sticks to the wall surface which makes it sufficiently damp-proof.

e. By use of Special Construction Techniques

Some of the special construction techniques that can be used for damp proofing are as follows:

a. Construction of the external wall of sufficient thickness can also be used as the damp proof course.

b. Use of high-quality bricks in the construction of the external walls.

c. Constructions of the structural walls in rich cement mortar.

d. Fixing down the water pipes sufficiently so that water may not leak through the junction of the wall and roof.

e. Construction of the cavity walls.

7. References1. Content Filter & Authenticity Checking Team, Dream Civil International (Our team checks every content & detail to maintain quality.) |

Read More: Carpet Area