Table of Contents

Construction Joint in sites are provided as the break or split made in concrete or occasionally steel structures to overlook the effect of contraction, expansion, movement, and settlement in structure with a modification in the exterior environment.

These joints are kept hollow or filled with resilient and flexible fabrics like wood, elastomers, fiber, rubber, plastic, bitumen asphalt mix, etc. Joints can be kept between wall and column, slab and beam, long walls, concrete floor, rigid pavement, Bridges, railway tracks, etc.

1. Construction Joint

These joints are kept for the objective to divide the large voluminous concrete work in a specialized way so that there would be no problem with in-work during construction as well as the structural strength of the structure wouldn’t be affected.

Construction joints are done to prepare purposefully, during the actual work of construction, and various adverse circumstances might arise.

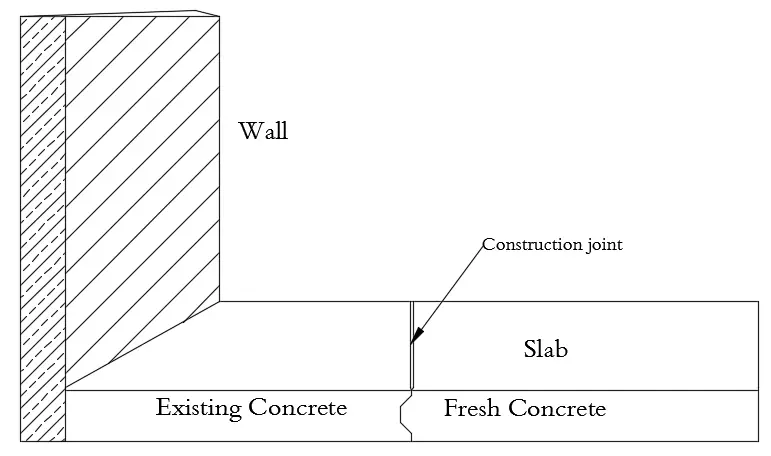

At such time a construction joint also may be induced. The unfavorable condition generally seizes the work, and thus the part of concrete in the structure might get hardened with time. Thus such old concrete (harden concrete) and new concrete to be placed during the resume of work are necessarily separated by unintentional instructions joints.

In such a situation such a construction joint is specially named a “Cold joint”. However such a joint should be conferred with the structural engineer, and cannot be randomly made. The engineer studies the stress conditions at that point and only decides whether to keep their joint and continue to work or not.

If joints on such points are analyzed to be not feasible then, the whole concrete work done previously might need to be demolished.

The construction joint is generally adopted in long construction works as the formation of very large slabs, in the construction of long retaining walls along the road, irrigation channels, etc.

The construction joints should not be located near the centroid level of the section as their transverse shear stress is very high. The construction joints are provided with “keys” at suitable spacing. The keys are interlocking structures made at the end of construction at the joint.

In resuming the work at joints (especially cold joints) the surface of the joint must be cleaned.

The construction joints are needed to be supplied with the load transfer device if the entire load is to be distributed overall structure. This generally happens in the rigid slab where there is a high amount of traffic movement. Under such conditions, they are connected with dowel bars and tie bars.

The construction joints are also classified into various types according to the method by the end of the joint face is constructed:

a. Butt type

b. Tong and groove type

c. Butt type with dowels

d. Butt type with tie bars

2. Features of Construction Joint

i. It is used where multiple concrete placements have to be done.

ii. These joints are kept where the process of concrete pouring has been stopped.

iii. They are essential because it is impractical to place concrete in a continuous operation, except for very small structures.

iv. Construction joints may be run horizontally or vertically depending on the placing sequence prescribed by the design of the structure.

v. It should be located along or near the plane of maximum shear.

| Read Also: Spatter Dash |