Table of Contents

Floors of modern buildings are invariably made of reinforced cement concrete (R.C.C.), because of the inherent advantages of this type of construction. Concrete, though strong in compression, is weak in tension.

However, it. is suitably reinforced with the help of steel bars which take the entire bending tension. Due to this, the overall thickness of R.C.C.

Floors are comparatively small, thereby reducing the self-weight of the floor itself. R.C.C. floors are also comparatively fireproof and damp-proof. The method of construction is also easy except that centering is required.

These floors can also be used on large spans, and therefore, more suitable for big size rooms, halls, etc.

2. Types of Reinforced Cement Concrete Floors

Reinforced cement concrete floors can be classified into the following types:

i. Simple slab flooring

ii. Reinforced brick flooring

iii. Beam-slab flooring

iv. Flat slab flooring

v. Ribbed flooring or hollow tiled flooring

2.1. Simple Slab Flooring

In simple R.C.C. flooring, the R.C.C. slab bends towards, causing tension at bottom fibers at the mid-span. Due to this mild steel bars reinforcement is placed at the bottom of the slab, keeping a minimum clear cover of 15 mm.

Half of these bars are bent up near the ends to take up negative bending moment caused due to partial fixity at the ends.

This main reinforcement is placed in the direction of the span of the slab, which is equal to the width of the room, especially when the length of the room is more than 1.5 times the width of the room.

Such a slab is known as One way reinforced slab. Nominal reinforcement (known as temperature/distribution reinforcement) is placed in the perpendicular direction. Hooks are placed at the end of each plain bar, though these are not required in ribbed bars (tor-reinforcement).

The bearing of the slab in the wall should neither be less than its thickness, nor less than half the width of the wall. Such slabs are quite suitable and economical for spans up to 5 m. The slab is cast on timber or steel shuttering.

After erecting the centering, properly bent reinforcement is placed in position. Distance pieces of stone or concrete are placed between the reinforcement and the shuttering plate so that proper cover is maintained. Cement concrete of appropriate mix (usually M20 mix or 1:1½: 3 mix) is then poured and well-compacted.

The slab is then properly cured. Shuttering is removed only when the concrete has been fully set. When the length of the room is less than 1.5 times the width of the room, the slab spans/bends in both directions. It is essential to provide reinforcement, in both directions Such a slab is, known as a two-way reinforced slab.

At the corner, suitable mesh reinforcement is provided at the top and bottom, to prevent their lifting. The plan of the reinforcement of a two-way slab, at its top and bottom.

2.2. Reinforced Brick Flooring

Reinforced brickwork is a typical type of construction in which the compressive strength of bricks is utilized to bear the compressive stress and steel bars are used to bear the tensile stresses in a slab. In other words, the usual cement concrete is replaced by bricks.

However, since the size of a brick is limited, continuity in the slab is obtained by filling the joints between the bricks with cement mortar. The reinforcing bars are embedded in the gap between the bricks, which are filled with cement mortar. Such type of construction is quite suitable and cheap for small-span floor slabs carrying comparatively lighter loads.

The depth of the reinforced brick slab is governed by the thickness of the bricks available. Modular bricks are 10 cm thick (nominal). Hence the thickness of the slab may be kept at 10 cm or 20cm.

If 15 cm thickness is required from the design point of view 5 cm thick tiles are used on the 10 cm thick bricks to make a total thickness of 15 cm.

The joint between the two layers of tile and bricks is filled with cement mortar. Before we use the bricks should be thoroughly soaked in water. The reinforcing bars put in the joints should not come in contact with bricks.

When two layers of bricks are used, vertical joints in the bricks should be used (staggered) so that the slab does not shear along the joint.

The bricks near the edge should rest half on the bearing wall so that the vertical joint above the edge of the wall is avoided. First-class bricks should be used for such work.

Cement mortar used to fill the joints etc. should 1:3 ratio, with a proper water-cement ratio to make the mortar workable.

The width of the joint between adjacent bricks is generally kept equal to 2 cm. The compressive strength of reinforced brickwork is sometimes increased by providing a wider gap (say about 4 cm) between the bricks and providing a 2.5 to 5 cm thick layer of cement concrete on the top of the bricks.

| Read More: Segregation in Concrete |

2.3. Beam-slab Flooring

When the width of the room becomes more, the span of the slab increases, and the simple R.C .C. slab becomes uneconomical. In that case, the floor structure consists of R.C.C. beams and slabs cast monolithically.

The beams known as T-beams, act as intermediate supports to the slab which is continuous over these beams. When the size of the room (i.e. hall) is very large, these floor beams, are supported on longitudinal beams which, in turn, are either supported on R.C.C. columns or end walls.

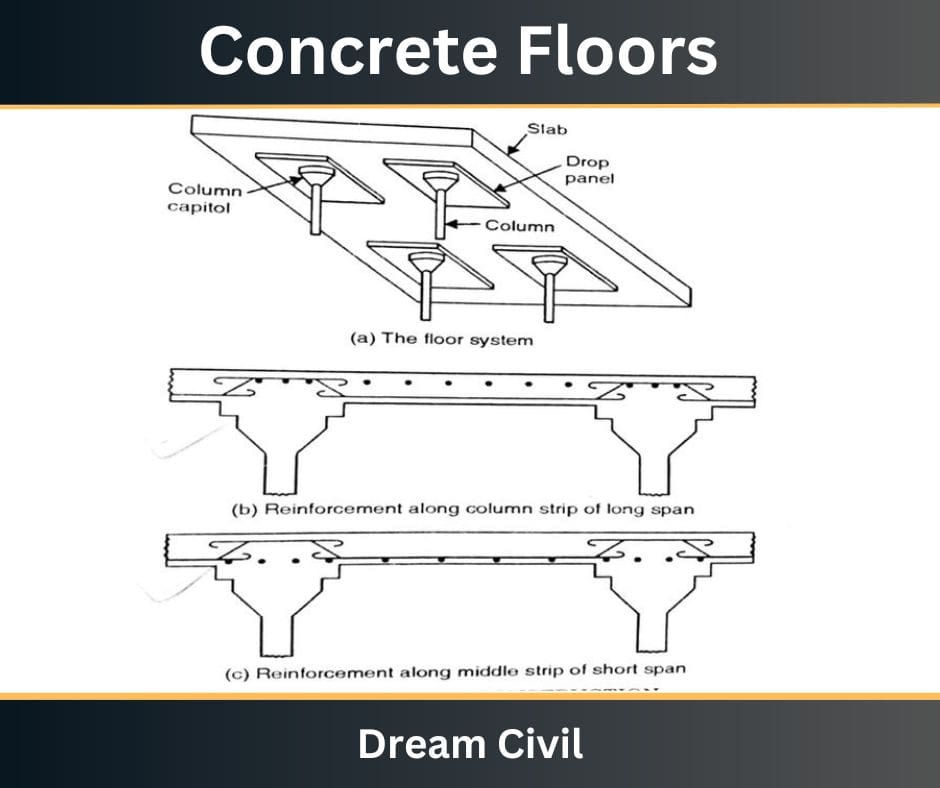

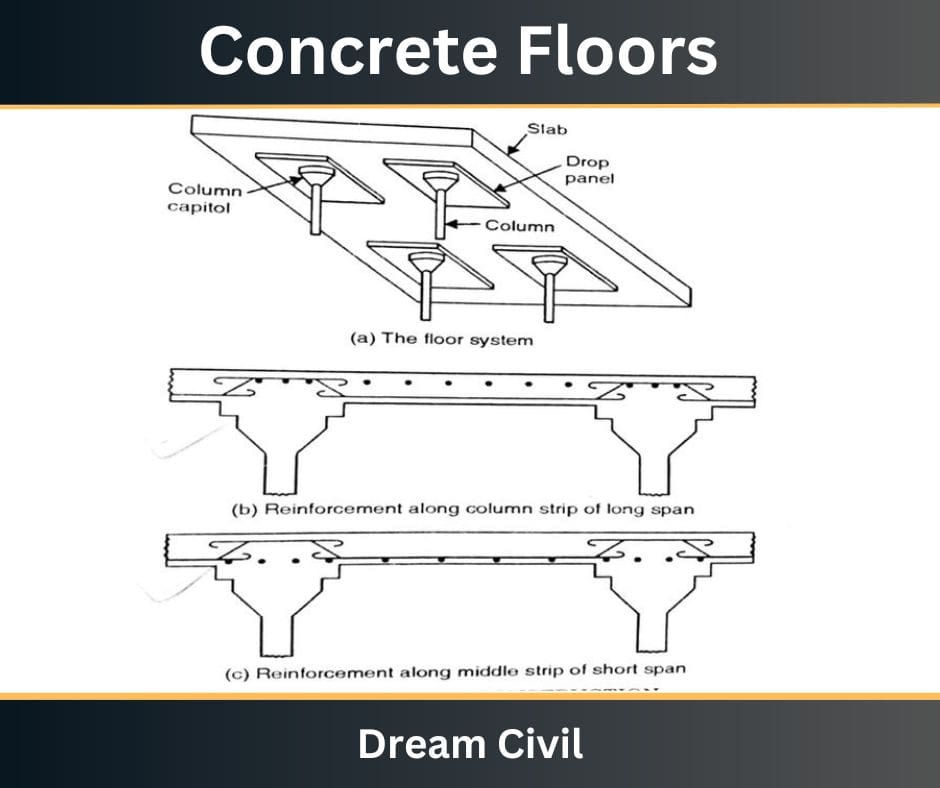

2.4. Flat Slab Flooring

A flat slab is a typical type of construction in which a reinforced slab is built monolithically with supporting columns and is reinforced in two or more directions, without any provision of beams.

The flat slab thus transfers the load directly to the supporting columns suitably spaced below the slab. Because of the exclusion of beam systems in this type of construction, a plain ceiling is obtained, thus giving an attractive appearance from an architectural point of view.

The plain ceiling diffuses the light better and is considered less vulnerable in case of fire than the usual beam slab construction. Concrete is more logically used in this type of construction, and hence in the case of large spans and heavy loads, the total cost is considerably less.

The slab in a flat slab construction may be either with a drop or without a drop. Drop is that part of the slab around the column which is of greater thickness than the rest of the slab.

Reinforcement in the slab can be arranged either in a two-way system or in a four-way system.

A two-way system of reinforcement is commonly adopted for slabs subjected to ordinary loading conditions.

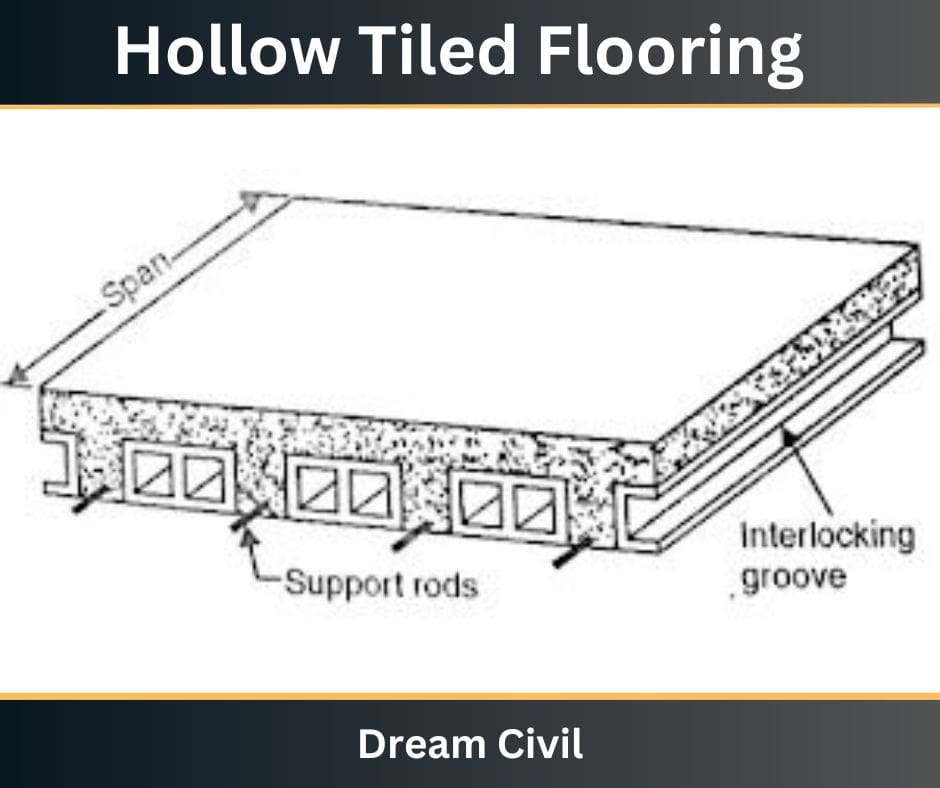

2.5. Ribbed Flooring or Hollow Tiled Flooring

Concrete is incapable of resisting tension which is caused by the lower part of the thickness of the slab. This lower part does not partake in load-bearing, and hence part of it can be replaced by hollow tiles so that the weight of the slab is reduced.

This results in a ribbed floor system. Unlike T-beam. construction, ribs of hollow tile construction are closely spaced.

The clear spacing of ribs depends upon the size of hollow blocks available, but it should normally not exceed 50 cm. The width of ribs may vary between 6 to 10 cm. The span of ribs may be much as 7 m.

However, when the span exceeds 3 m, lateral ribs of the same width as the main longitudinal ones are provided at intervals between 1 to 3 meters. In that case, longitudinal ribs are designed as continuous beams.

Main reinforcement is provided at the bottom of the rib. To resist the support moment (negative) an additional bar is placed at the top of the rib section. A minimum cover of 2.5 cm is provided. The depth of the rib is calculated on the basis of the bending moment as well as the cost ratio of steel. and concrete.

The depth of the rib is usually kept as at least L/20 with free support and at least L/25 with fixed support, where L is the span of the ribs.

Due to the small span, the slab is normally not analyzed. A slab thickness of 4 to 5 cm is generally provided. To check its cracking and to distribute the load properly, shrinkage and temperature

This was for the Concrete Floors.

3. References1. Content Filter & Authenticity Checking Team, Dream Civil International (Our team checks every content & detail to maintain quality.) |

Read Also: Types of Cracks in Concrete Columns