Table of Contents

In this article, we will discuss the compaction factor formula of concrete.

1. Introduction

Concrete is the composite material that is composed of a mixture of fine and coarse aggregates bonded together with biding material which hardens over time. The binding material mostly includes fluid cement paste, lime putty, lime, etc.

The ratio of densities of the same fresh concrete, one results from the test considering standard conditioning of placement and another from the full compaction of concrete through vibration or external work.

The calculation of compaction factor is done to calculate to what extent the volume of the fresh concrete can be compacted in formwork during construction.

2. Apparatus Required

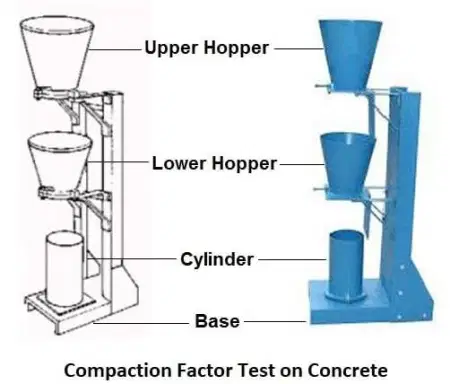

The apparatus is made in such a way assuming the normal method of pouring concrete in the field. The British have taken two cones of frustum utilized as hoppers for placement of concrete in the cylinder kept one above another at a certain height.

It is done to use the self-compacting ability of the concrete due to its self-weight. The hoppers inside the surface are well-polished to decrease friction and contain a hinged door at the bottom which can be open once they are filled with concrete.

The second hopper is smaller than the top hopper but includes the same amount of concrete denoting there is compaction on fall. This is prepared in order to lower the influence of the filling top hopper by individual person in a different way. The standard dimensions of the apparatus are given below in a table as described by BS 1881-103.

The other instruments required are a simple shovel, mechanical mixture, trowels or screed plates, and the tamping rod with 16mm diameter 610mm long with the rounded end at the bottom of the mechanical vibrator arrangements.

| Read Also: U Box Test on Fresh Concrete |

3. Procedure

The following procedure is carried out:

1. First of all the concrete of needed workability with a changed amount of water content and also the addition of admixture, that are to be utilized in the field are made. The concrete is then placed into the first hopper of the instrument.

2. The pouring should be very light considering no external work is carried out to it and no compaction done in the process. Then the bottom of the upper hopper is unlocked quickly and thus is directly captured on the second hopper.

3. The concrete might be overflow to some areas if the concrete is not placed in a standard way in the first hopper. Then the bottom end of the second hopper is unlocked and the concrete is permitted to fall into the cylinder.

4. The excess concrete in the cylinder is then cut off through the trowel to the top of the cylindrical mold. The density is calculated with the help of weighing mass and the known standard volume of a cylinder.

5. Then the process for calculating the density of fully compacted concrete mass is done. This can be carried out by two approaches, theoretical and practical. The theoretical approach contains estimations of compacted density by the absolute volume of mixed ingredients and utilizes the equation and Compaction factor formula below.

4. Compaction Factor Formula of Concrete

Compaction factor = (W1-W) /(W2-W)

The results of calculations usually lie within the range of 0.7-0.9. And with help of this value and reference of another test their workability is calculated.

| Read Also: L Box Test |