Table of Contents

When the water flowing in a long pipe is suddenly brought to rest by closing the valve, the momentum of the flowing water will be destroyed and consequently, a wave of high pressure will be set up. The kinetic energy of flowing liquid will be converted into the internal pressure energy with the rising of pressure.

This wave of high pressure will be transmitted along the pipe with a velocity equal to the velocity to the velocity of sound and may create a noise called knocking. This phenomenon of a sudden rise in pressure in the pipe is known as a water hammer or water blow.

1. Causes of Water Hammer Effect

The water hammer effect is originated due to changes in velocity which are driven by:

✔ Due to the sudden closing of the valve

✔ Due to Power failure

✔ Beginning or closing down of pumps (hydro turbines)

✔ Changes in power demand in turbines

✔ Fracture of the line. etc.

✔ Mechanical collapse of the managing devices like the valve.

2. Effects of Water Hammer Effect

✔ High-pressure fluctuations in pipelines

✔ Rupture of pipe or valve if beyond the safety limit

✔ Higher pressure requirements for the design of pipelines and penstocks etc.

3. Solutions for Water Hammer

Due to the decrease in the chance of the water hammer effect following factors are considered:

✔ Steam lines should continuously be established with a slight slope (gradient) in direction of flow.

✔ Installing steam traps at regular intervals and also at the low points. This ensures the removal of condensate from the steam system as soon as it is formed.

✔ Hanging pipes should be neglected by equipping suitable support. Sagging pipes can initiate a pool of condensate in the pipework, advancing the possibilities of a water hammer.

✔ Workers should be instructed to open the isolation valve gradually during the start-up modes.

✔ Drain pockets should be adequately sized to make sure that condensate just does not jumps over them. Rather, the drain pockets should be sized sufficiently so that all the condensate comes into the trap.

✔ Eccentric reducers can be carried out against concentric reducers.

4. Water hammer formula

Time required by pressure wave to travel from the valve to tank to valve.

Time is consumed = Distance spanned from valve to tank and back/ Velocity of pressure wave

T = (L+L)/C

| T = 2 L/C |

Let ‘t’ be the actual time taken for a closer of valve

If “t>T” then such closure is referred to the as gradual closure of the valve.

When valve closure is gradual fluid is considered to be incompressible and pipe material is

considered rigid.

If “t<T” then such closure is referred to the as instantaneous or sudden closure of the valve.

When valve closure is instantaneous or sudden fluid is considered to be compressible and pipe

material is considered both as rigid and elastic.

5. Pressure Rise Due to the Gradual Closure of the Valve

Consider flow occurring in a rigid pipe of length L which is bought to rest by gradually closing the valve at time t, let c be the speed of pressure wave produced, assume ρ be the density of the flowing fluid, and since the valve closure is gradual fluid is considered to be incompressible.

Retardation due to valve closure =V/t

This produces retardation force along the whole length of the pipe

𝐹 = 𝜌𝐴𝐿 ∗ 𝑉/𝑡

𝐹/𝐴= 𝜌𝐿𝑉/𝑡

𝑃 = 𝜌𝐿𝑉/𝑡

𝑃/𝜌𝑔=𝐿𝑉/𝑔𝑡

This gives rise in pressure due to gradual valve closure.

6. Pressure Rise Due to the Sudden Closure of the Valve

A. Pipe material is considered rigid and fluid is compressible

Consider flow occurring in a rigid pipe of length L, cross-sectional area A which is bought to rest

by suddenly closing a valve at time t, let c be the speed of pressure wave produced, assume ρ be the density of the flowing fluid and K be the bulk modulus of elasticity of fluid.

When fluid is bought to rest there is a loss in kinetic energy of the fluid this loss in kinetic energy is converted to gain in pressure energy, since the fluid is compressible this pressure energy causes a rise in internal energy of the fluid material.

Thus by conservation of energy

Loss in kinetic energy of the fluid = Gain in internal energy of the fluid

Loss in kinetic energy of the fluid throughout the pipe when velocity is reduced to 0 from

V= (1𝜌𝐴𝐿𝑣2)/2

Gain in internal energy of the fluid= ∫𝑣𝑜𝑙 (𝑠𝑡𝑟𝑒𝑠𝑠2/(2∗𝐸𝑙𝑎𝑠𝑡𝑖𝑐𝑖𝑡𝑦)) 𝑑𝑣

Gain in internal energy of the fluid throughout the pipe is = (𝑃2𝐴𝐿)/2𝐾

Thus, (1𝜌𝐴𝐿𝑣2)/2= (𝑃2𝐴𝐿)/2𝐾

𝑃 = 𝑣𝜌√𝑘/𝜌

𝑃 = 𝑣𝜌𝑐, where c is the celerity.

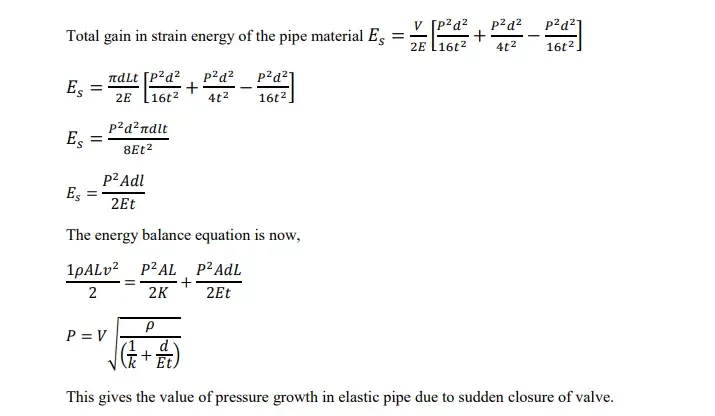

B. Pipe material is considered elastic and fluid is compressible

Consider flow occurring in an elastic pipe of length L, diameter d, and young’s modulus of elasticity E, which is bought to rest by suddenly closing a valve at time t, let c be the speed of pressure wave produced, assume ρ be the density of the flowing fluid and K be the bulk modulus of elasticity of fluid.

Since the pipe material is elastic, the total loss in kinetic energy due to valve closures is converted to gain in internal energy of fluid due to its compressibility and gain in internal energy of pipe material due to its elasticity.

Thus by conservation of energy,

Loss in kinetic energy of the fluid=Gain in internal energy of the fluid+ Gain in internal energy

of the pipe material.

Loss in kinetic energy of the fluid throughout the pipe when velocity is reduced to 0 from V= (1𝜌𝐴𝐿𝑣2)/2

Gain in internal energy of the fluid= ∫𝑣𝑜𝑙 (𝑠𝑡𝑟𝑒𝑠𝑠2 / (2∗𝐸𝑙𝑎𝑠𝑡𝑖𝑐𝑖𝑡𝑦))𝑑𝑣

The gain in internal energy of the fluid throughout the pipe is = (𝑃2𝐴𝐿)/ 2𝐾

The gain in internal energy of the pipe material per unit volume

𝐸𝑠/V = (F2l+ Fc– (2xflxfc)/m)/2E

Where 𝑓𝑙 & 𝑓𝑐 is the longitudinal and circumferential stress developed due to expansion of the

walls of the pipe, (1/m) is the Poisson’s ratio. Putting Poisson’s ratio as 0.25 or m=4,

The volume of the pipe material 𝑉 = 𝜋𝑑𝐿𝑡

This gives the value of pressure growth in the elastic pipe due to the sudden closure of the valve.

7. Water Hammer Effect Relieving Devices

The water hammer effect or hydraulic transient has a serious effect at the pump position, the propagation of high-pressure waves may explode the pipeline system and damage other pipeline tools. Relieving devices have to be established to destroy this effect.

Example of Relieving devices in hydropower plant:

A surge tank is a suitable example of one such device that can be established to decrease the water hammer effect.

✔ Surge tanks are provided at the head of the penstock pipe and the end of the tailrace tunnel.

✔ It prevents high-pressure rise by receiving water from the pipeline helping to reduce the water hammer effect.

✔ Constructing a surge tank guides the economic arrangement of the pipeline system.

| Read Also: Hydraulics Fluid Mechanics Objective Questions |