Table of Contents

Stirrups may be defined as a closed-loop bars tied at regular intervals in beam reinforcement to hold the bars in position.

Types of stirrups depend upon various factors which we will be discussed below.

Lateral ties are employed to control the position of the reinforcement in a column without bothering the concrete space.

Both are the same and only vary in their placement. If it is set in a column it is known as lateral ties. If it is set in a beam it is known as stirrups. The operations of both vary for beam and column.

Mainly the stirrups are developed in a rectangular or square shape but in a few circumstances, they may be equipped in circular or diagonal.

1. Uses of Stirrups

The uses of Stirrups are as follows:

a. Stirrups are mostly employed to maintain the main reinforcement rebars jointly in RCC Structure.

b. Stirrups are needed to hold safe the columns and beams from buckling and help in the resistance to lateral stresses (e.g., earthquake loads).

c. Stirrups are employed to deliver strength to the reinforcement of steel bars.

d. Its resistance to shear and torsion is excellent.

e. Stirrups are employed to handle shear capacity more actually.

f. It improves the column’s compressive strength.

g. It can increase the column’s ductility.

h. Stirrups keep a column’s main reinforcement from buckling.

i. It inhibits the movement of the primary reinforcement during the concreting process.

j. Stirrups are employed in beams for the same purpose as in columns for lump-sum calculations.

k. To produce longitudinal bars with lateral confinement.

l. During construction, keep longitudinal bars in place.

m. It keeps the concrete in the core, making it more ductile and strong.

n. It prevents individual bars from buckling prematurely.

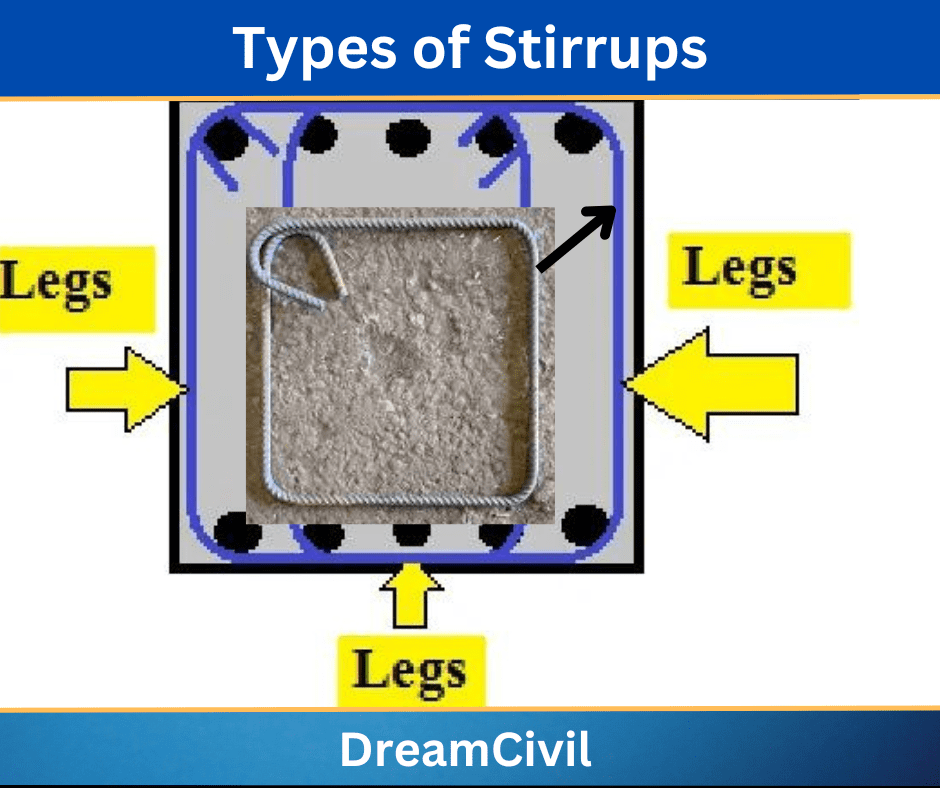

2. Types of stirrups

i. According to the Shape of Stirrups.

a. Square stirrups

b. Rectangular Stirrups

c. Triangular Stirrups

d. Circular stirrups

e. Helical stirrups

f. Diamond stirrups

ii. According to the Nature of the Stirrups

a. Single-legged stirrups

The stirrups that exist on a single leg are known as single-legged stirrups.

b. Two-legged stirrups (Closed Stirrups)

Stirrups with two legs are the commonly employed stirrups in the field of construction. This type of stirrup needs a minimum of four rods to be met.

c. Three-legged stirrups

The stirrups exist on three legs known as three-legged stirrups.

d. Four-legged stirrups

The four-legged stirrup is prepared up of two overlapping stirrups that don’t wrap all of the rods.

If your reinforcement has eight rods in two rows of four, the two overlapping stirrups will surround six rods each, with the four in the center surrounded by both.

e. Five-legged stirrups

The stirrups exist on five legs known as five-legged stirrups.

f. Six-legged stirrups (Closed Stirrups)

Instead of eight rods, a six-legged stirrup can be used to support the same eight-rod configuration.

In this arrangement, a single stirrup encircles all eight rods and extra legs give extra support. These extra legs are normally placed between two rods that are close.

g. Seven-legged stirrups

The stirrups exist on seven legs and are known as six-legged stirrups.

h. Eight-legged stirrups

The stirrups standing on eight legs are known as six-legged stirrups.

3. Some Design Consideration

i. How To Calculate The Length Of a Stirrup?

Computing the length of a stirrup is a really unchallenging operation. Here is what you can do:

Assume that you’re computing the length of a stirrup employed in a 0.40 m x 0.40 m beam; now find the perimeter length of the beam,

i.e.,

0.40 m x 4 sides = 1.60m.

Now you have to take clear cover (which is 1 inch for all sides, both in vertical and horizontal directions) gapping for concrete.

minus 8 inches (an inch is 2.54cm), which is precisely 0.20m from the beam’s perimeter length, gives us 1.40m.

Lastly, you need to provide 2 inches to each end of the stirrup rod while bending to a square shape which makes 1.50m (1.40m + 0.10m)

ii. How Far Apart Do Stirrups Have To Be?

Throughout the lapping length, the vertical stirrup gapping should be 100 mm c/c. Stirrups must have a minimum diameter of 8 mm.

iii. Stirrup Spacing In Beam Formula

a. The maximum stirrup spacing should be according to IS 456, 0.75 d.

b. Vertical stirrups must be kept no more than 0.75d or 300mm apart.

IS: 456 describes the requirements for fixing the vertical stirrup spacing in a structural member, which must not be greater than the least of the following:

a. least lateral dimension

b. The diameter of the smallest longitudinal bar is multiplied by sixteen.

c. 300 millimeters

4. Objective of Stirrups

The objective of stirrups is as follows:

a. It maintains the rebars in place and controls deformation.

b. It places the rods in the exact alignment.

c. To ensure the beam and column from buckling and shear failure.

d. The stirrups withstand the rods under compression or tensile force.

e. The spacing of stirrups will be various established on the design for both the column and beam.

f. The lowest spacing is 100 mm and the maximum is 250 mm, relying on the diameter and number of the rod available.

5. Difference between Stirrups and Ties

The role of both stirrups and ties in the RCC structure is identical and delivered for the identical aim but the difference is that stirrups are employed in horizontal member-like columns and ties are employed in vertical member-like columns.

6. Suitable Diameter of Stirrups

The diameter of the stirrups to be employed in the RCC structure relies upon the shear stress involved in the structure. There is no specified diameter for the stirrups it purely depends upon construction.

But normally, for residential buildings, the right size of stirrups ranges from 6 mm to 10 mm.

For commercial and vital buildings like hospitals, shopping malls should employ stirrups of more than 8 mm. The size of such types of stirrups may range from 9 mm to 10 mm.

7. References1. Content Filter & Authenticity Checking Team, Dream Civil International (Our team checks every content & detail to maintain quality. ) |

Read Also: Top Tiles Company in India