Table of Contents

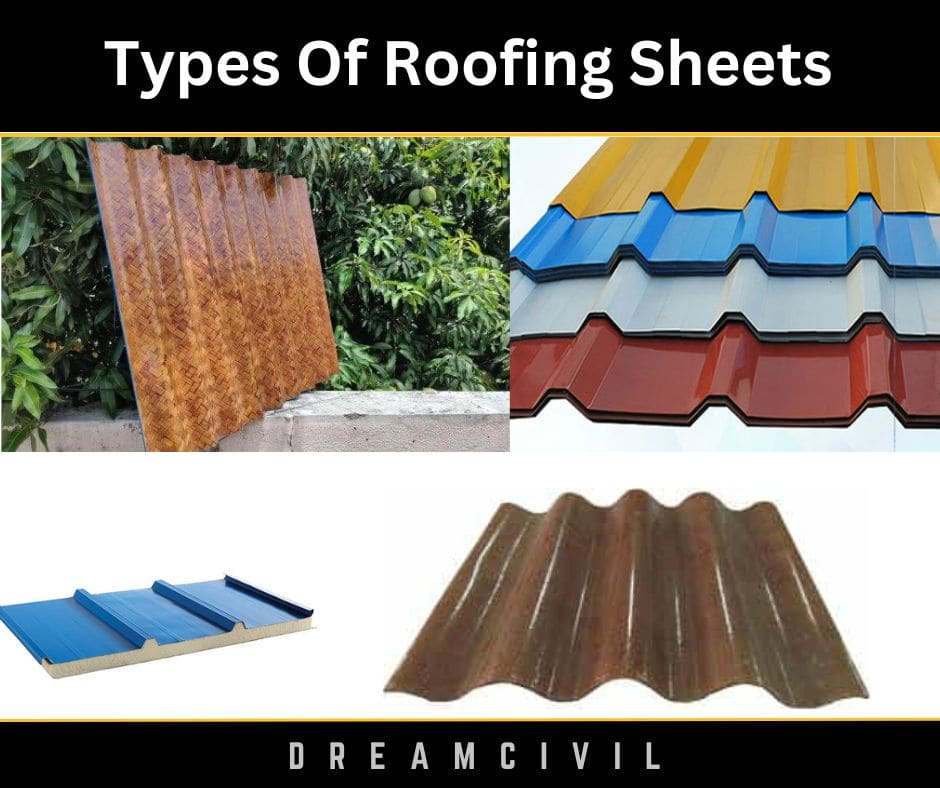

In this article, we will discuss the type of roofing sheets.

A roofing sheet may be defined as a modern type of roof covering, specifically when compared to roofing materials such as thatch or roof tiles, which have been employed for centuries, if not thousands, of years. The global roofing industry has advanced with the growth of new roofing materials.

1. Different Type Of Roofing Sheets

a. Corrugated Roofing Sheets

Because of its form, corrugated roofing is admiringly durable. Due to the screws for fastening pierce through the peak of the ribs, these sheets need support strips to stabilize the material. The ribs and valleys’ curvature inhibits the screws from sufficiently filling in the valleys.

The corrugated design, flimsy and lightweight metals like aluminum can also be equipped to resist decades of weather action.

Galvanized steel sheet is the most standard corrugated sheet, commonly employed as the base material. Garages, porches, and sheds can all profit from these roofing sheets.

b. Aluminum Roofing Sheet

Aluminum Roofing sheet is a famous roofing material in numerous houses since it is long-lasting, energy-efficient, low-maintenance, and cost-effective.

It is anti-corrosive, fire-resistant, easy to fix, and can handle severe weather circumstances.

Aluminum is a lightweight metal roofing material that allows to decrease structural load.

c. Asbestos Cement Roofing Sheet

This roof construction method used asbestos fiber as a reinforcement material with cement.

Asbestos fibers deliver the roof sheet body rigidity and stiffness, authorizing it to maintain its size and shape without cracking.

d. Polycarbonate Roofing Sheet

Polycarbonate roofing sheets arrive in a mixture of thicknesses and grades. They’re much lighter than steel, yet they’re solid and unsusceptible to infringement and splits.

They’re comfortable to operate with and can be welded or fixed using screws and support rods.

These sheets can even be cut effortlessly by employing sharp-edged scissors and circular saws without employing other tools or machines.

Because polycarbonate roofing sheets are so sturdy and flexible, they permit more imaginative design in their employed structures.

One of the most beneficial properties of polycarbonate is that it permits maximum sunlight while blocking dangerous UV radiation.

As an outcome, it’s the most practical way to permit as much light as possible while evading harm. These sheets are generally used in large-scale commercial and industrial constructions.

e. Fiber Reinforced Plastic Roofing Sheet

Fiber-reinforced plastic (FRP) is a thermosetting resin and fiber composite material. Fiber is a reinforcing material, providing rigidity and keeping the molded shape. Roofing sheets arrive in different colors and styles and can be flat or corrugated.

The degree of opacity in these sheets is changed during manufacture, creating it easier to select the appropriate sheet for the sunlight needed in the roofed space.

They are anti-corrosive and straightforward to repair, outcoming in lower maintenance expenses.

f. Unplasticized Polyvinyl Chloride Roofing Sheet

Because it is hard and unyielding, UPVC, or unplasticized polyvinyl chloride, varies from PVC in flexibility functions. UPVC does not contain plasticizers added to its PVC substance, so it is not flexible, hence “unplasticized.”

It is also solid and low-maintenance, just like the PVC roofing sheet. It’s an incredible heat and energy insulator usually employed as a roofing material to cover against corrosion and harsh temperatures.

Because UPVC is robust and inflexible, it is problematic to destroy, creating it excellent for enhancing the security of residential and commercial facilities in case of a robbery or break-in.

g. Plastic Roofing Sheet

PVC-based plastic roofing sheets are identical to bitumen-based roofing sheets in multiple forms. These plastic sheets are excellent for landlords examining a low-cost, lightweight roof sheet with a corrugated form element.

Because of its high light transmission, PVC roofing is usually a low-cost option to roof lights, permitting you to flood an area with light. However, their low-cost PVC sheets are adorable and long-lasting.

Plastic roofing sheets are usually employed as a substitute for polycarbonate roofing. It is due to the transparent finishes being available at a lower cost and easier to install. Install PVC roofing only requires essential fixings and flashings rather than a complete roofing system with glazing bars and other components.

These sheets can merge with other materials to make a ceiling with a mix of opaque and translucent parts that allow light to move through to the space below.

h. Bitumen Roofing Sheet

Bituminous roof sheets cover residential and commercial structures. As the name suggests, these are rolls of coatings at the site.

After that, they’re sprinkled out on a solid surface. The considerably famous type of Roofing Sheets based coating is a bituminous waterproofing film. Adjacent membranes are bound to operate the same hot adhesive.

The same air gun is even employed to create joints between adjacent layers. The sheets are surrounded by approximately 100 mm to make a waterproof connection.

i. Color Coated Roofing Sheet

Sheets are covered with 55% aluminum, 43% zinc, and 1.5% silicon and combined with high–quality colors that satisfy certain specifications in this form of roof sheet steel and another alloy.

It is also available in a single-color-coated version and a multicolor-coated version in various colors.

This color layer gives the item a royal appearance while providing the benefit of being non-corrosive.

j. Galvanized Iron Roofing Sheet

The galvanized iron coating has an outstanding metallurgical structure that shields against abrasion and mechanical deterioration during shipment, installation, and service.

Galvanized iron roofing sheets are designed to protect any damaged areas of the sheet automatically.

The sheets act as a cathode or sacrificial layer of safeguard for any tiny areas that may be harmed during shipping. As an outcome, the covering covers the whole length of the sheets.

k. Rubber Roofing Sheet

Secondary roofing material is majorly gladded over the current roof to deliver heat opposition and waterproofing to complete a single sheet frame.

Rubber roofing sheet is primarily used for rehabilitation. Ethylene Propylene Diane Monomer Rubber is employed in this sheet, taped and bonded on top of the existing surface.

l. PUF Roofing Sheet

Polyurethane foam (PUF) is a kind of polyurethane foam. Between two sheets of similar material and dimension, the foams are sandwiched. These sheets are employed where thermal insulation is necessary.

m. Bio-Composite Roofing Sheet

A bio-composite is a material comprising a resin matrix and natural fiber reinforcing. Natural fibers were foremost employed as reinforcement in polymeric composites due to environmental problems and the high price of synthetic fibers.

Polymers from both renewable and nonrenewable origins create the matrix phase. It covers the roofing sheets from environmental degradation and mechanical damage, maintains the fibers, and shares the stresses.

n. Bamboo Roofing Sheet

Bamboo roofing sheets are made from a renewable natural resource and can save dwellings, storage facilities, animal pens, and other temporary and permanent structures.

They are the exact size of traditional corrugated roofing sheets and own the exact standard specifications. Bamboo roofs are better soundproof in the rain and cooler in the sun than that metal or plastic sheets.

According to an investigation, cows in bamboo-roofed shelters give more milk than those in corrugated zinc-roofed sheds due to the higher comfortable atmosphere.

2. Elements to Consider When Selecting Roofing Material

The elements that are required to be evaluated when selecting roofing material are as follows:

a. Material Weight

Some roofing materials are more severe than others. As a result, it’s an essential element to handle because it could compromise the structural integrity of your property.

Ensure your building is physically sound sufficient to keep the weight of your preferred roofing material.

b. Weather Condition

The weather conditions in your location will determine the material of the roof sheet. The roofing material is even heat and weather-resistant.

c. Color Variety

Select a roofing material founded on its coloring if you like a premium appearance or one that integrates with your overall aesthetic.

d. Maintenance

Think how much duration and work you can save on roofing upkeep. It’s worth mentioning that other materials, such as metal, need far less maintenance, creating them perfect for busy homes.

e. Overall Cost

Your funding is the one that establishes the technique right away. You can visit which roofing materials are available and which aren’t by considering how much you’re ready to pay. Hold in mind that more costly materials aren’t forever more valuable.

3. Advantages of Roofing Sheets

The advantages of roofing sheets are as follows:

a. The significant benefit of employing roofing sheets is that they may last up to 100 years since they do not rust and are one of the considerable long-lasting solutions.

b. Roofing sheets won’t decay and cannot be attacked by insects like termites.

c. They are majorly treated with chemicals inhibiting alga development during extreme rainfall.

d. Numerous roofing sheet materials are fireplace resistant, another benefit that may protect lives in an accident.

e. Because the sheets are lightweight, they are easy to fix.

4. Disadvantages of Roofing Sheets

The disadvantages of Roofing sheets are as follows:

a. Denting, bumping, and bruising are major common problems that are challenging to control while working with Roofing sheets.

b. Roofing sheets could be crushed or damaged as an outcome of hailstorms.

c. No suitable place where regular snow or hail occurs.

d. The installation price is a little more outstanding; however, the inexpensive maintenance cost creates up for it in the long term.

5. References1. Content Filter & Authenticity Checking Team, Dream Civil International (Our team checks every content & detail to maintain quality.) |

Read Also: Planned Preventive Maintenance