Table of Contents

A Trussed Tube systems are a type of tubular structural system that can be utilized in high-rise buildings to withstand lateral loads like wind and seismic forces. These lateral load resisting systems allow the building acts like a hollow cylindrical tube cantilevered perpendicular to the ground. Thus the structure shows a tubular manner against the lateral loads.

The tube system was introduced by the well-known structural designer Fazlur Rahman Khan in 1960. He is believed as the father of tubular design in structural engineering. The DeWitt Chestnut Apartment Building in Chicago was the initial tube-frame structure developed by Khan in 1963.

1. Types of Tubular Structural System

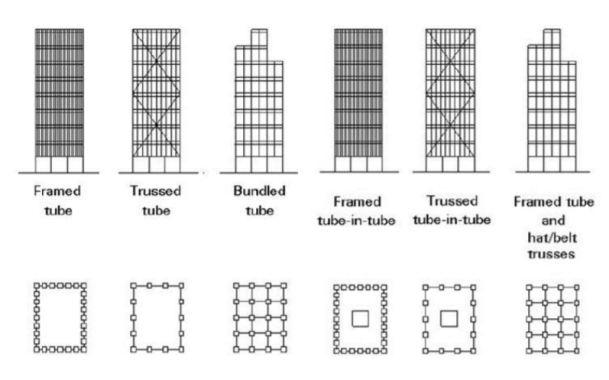

The major types of tubular structural systems are:

1. Framed Tube Structural System

The framed tube system is Khan’s most uncomplicated and first tubular structural system. The framed tube can be utilized for different floor plan figures like square, circular, rectangular, and freeform.

Framed tube structural system made of closely packed exterior columns that are precisely connected with deep spandrel beams running constantly across each facade and about the building corners.

This configuration improves the beam and column stiffness by reducing the clear span proportions and improving the member depth. Framed tube structural system is best for buildings with a height from 38 to 300 m.

2. Trussed Tube Systems

Trussed tube systems like frame tube systems are made of external columns that are rarer in number in contrast to framed tube systems that are positioned far apart. Trussed tube systems are also known as braced tube systems that are identical to the framed tube but have fewer external columns that span a distance apart.

These columns are attached utilizing steel bracing or concrete shear walls. This interconnection of external columns creates a rigid box capable of opposing lateral shear by axial force in members instead of bending or curving (flexure).

The requirement of wide column spacing in the trussed tube system permits precise area for windows.

3. Tube-in-Tube Structural System

Tube-in-tube structural system is also named the “hull and core” format. Here, a core tube is wrapped by an external tube. The core tube maintains the critical parts of a high-rise building like lifts, ducts, stairs, etc.

The external tube is the normal tube system that handles the majority of gravity and lateral loads. In this system, the internal and external tubes interact horizontally as shear and flexural branches.

4. Bundled Tube Structural System

In bundled tube structural system, there are many connected tubes to assemble a multi-cell tube. This arrangement jointly withstands lateral loads and overturning moments.

The tube-in-tube system is a considered cheap and versatile building technique that allows for the creation of interesting shapes. Willis Tower in Chicago is the first building to adopt a tube-in-tube structural design.

5. Hybrid Tube Structural System

Whenever the building design has slenderness or less strength and stiffness, a hybrid structural system is used. A hybrid tube structural system combines two or more structural forms in different parts of the structure. This system is more typical in complex building structures.

| Read Also: Flush Mortar Joint |