Table of Contents

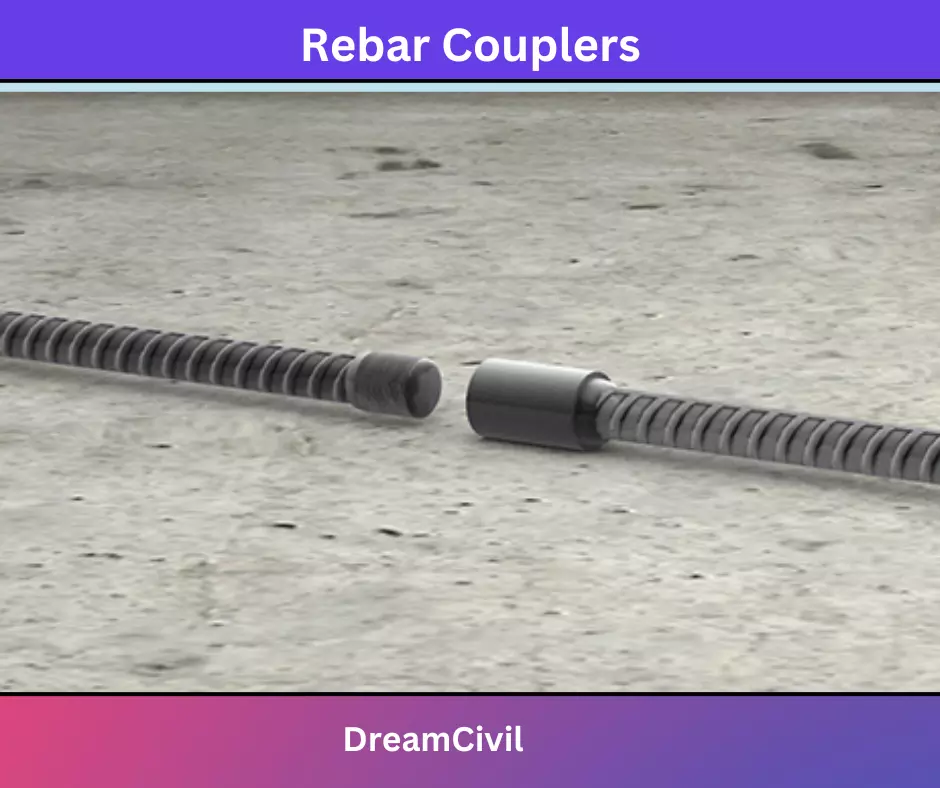

In this article, we will discuss rebar couplers.

| Summary: Rebar couplers are employed in reinforced concrete cement structures to change the system of lapping & welding in reinforcement. Couplers are employed where the long length of the bar is required or when connecting the additional bars to the end of existing bars are connected by wire next to each other. There is a waste of bars in the welding system & lapping system, alternative system is employed called a rebar coupler or coupler in reinforcement that gives an end-to-end connection for the continuous reinforcement of any structure. The coupler is cheap and cost-efficient unlike the lapping system, where some portion of the bar is wasted due to lapping. The Couplers are generally known as mechanical splices. It is employed in all construction such as the construction of buildings, bridges, dams, towers, etc. |

1. Types of Rebar Couplers

There are primarily two types of rebar couplers in reinforcement. They are,

a. Threaded rebar coupler

b. Roll thread coupler

c. Cold forged rebar coupler

d. Non-threaded coupler

e. Crimping rebar coupler

f. MBT coupler

1. Roll Thread Rebar Coupler

In this coupler, the coupler is threaded by a threading machine. To hold the bar in the roll thread coupler, the end of the TMT bars are threaded in the roll thread machine.

After that, the coupler fixing is accomplished to both ends of the TMT bar such as nut & bolt, for continuous reinforcement.

2. Cold forged rebar coupler

The cold-gorged coupler is also threaded by the use of a threading machine like a roll thread rebar coupler. But in this coupler, the end of the TMT bar is developed with the benefit of a forging machine by hydraulic pressure.

After the process of forging the end of the TMT bar losses, a minimal part of length & rises in thickness & the bar is threaded by the threading machine & is fitted to the coupler. It is given for big infrastructure projects & other government projects.

3. Crimping rebar coupler

It is also known as the first coupler in reinforcement in construction & after that threaded coupler was introduced. There is no thread in the crimping rebar coupler.

The rebar coupler is fitted in two ends of the TMT bar without thread & the coupler is crimped by a crimping machine. The crimping coupler is not economical & more material is used & the labor cost is also high.

A crimping coupler in rebar cannot be un-crimped after installation. Because of this, the crimping coupler system has failed in the market.

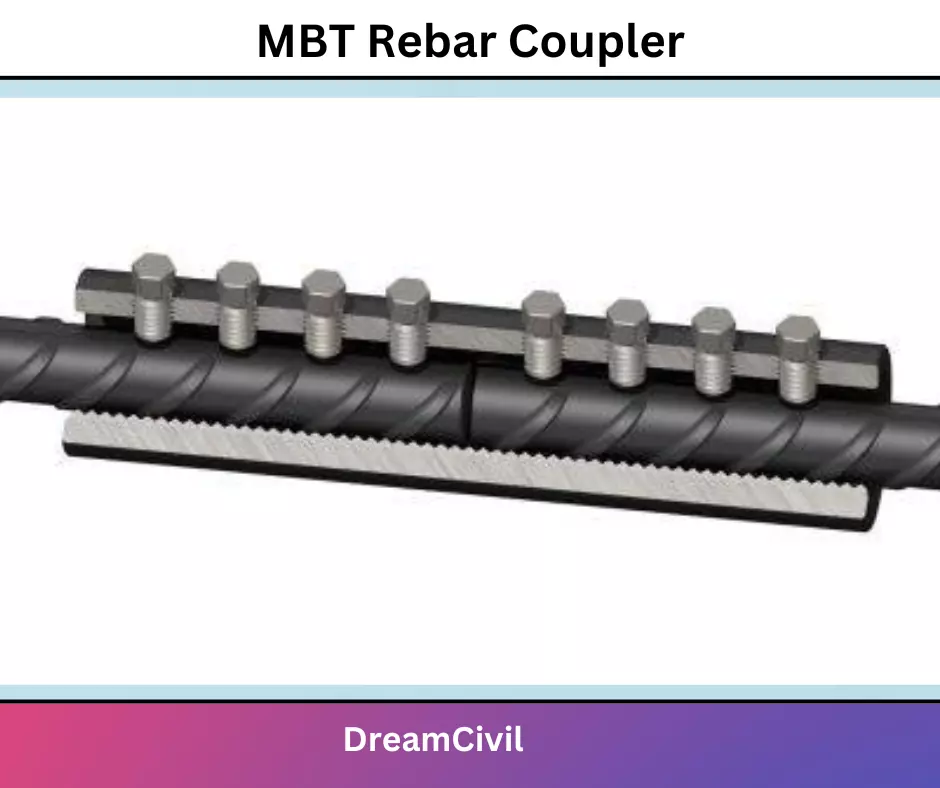

4. MBT Rebar Coupler

The MBT rebar coupler is prepared for the essential needs of continuous reinforcement.

The MBT coupler is employed in reinforcement when there is a smaller lap length & not much of a bar is left for continuous reinforcement. It is also employed in retrofitting constructions.

There are around six to eight bolts in the top MBT coupler. Its length is more than a threaded coupler. The strength of this coupler relies on the number of bolts present on it & with the use of these bolts the coupler in reinforcement is fixed.

2. Test of Rebar Coupler

The coupler in reinforcement is processed by different rebar coupler testing. Here is the list of tests of the coupler is as follows:

a. Cyclic tensile test

b. Low cycle fatigue test

c. High cycle fatigue test

d. Static tensile test

e. Yield strength of steel

f. Slip test

g. Chemical test

3. Benefits of Rebar Couplers

Some benefits of the coupler in reinforcement are as follows;

a. It has excellent quality control & is easy to handle.

b. The load transfer is reasonable.

c. The coupler does not make congestion.

d. The continuity load path is valid.

e. The rebar coupler is very economical compared to all the systems of joints in reinforcement.

f. The Coupler expands the work speed by short installment.

g. The connection check is easy & simple.

h. It enhances the service of the bar by not wasting bars like the lapping.

i. The coupler decreases the lapping length analysis.

j. It enhances structural integrity.

4. Drawbacks of Rebar Couplers

Some drawbacks of the coupler in reinforcement are given below;

a. Chance of misalignment in the attachment of 2 shafts which will make an extreme force on the coupling, bearing & shaft, causing them to wear prematurity.

b. It is hard to find a coupler in the market whose diameter is more than 32 mm.

c. Skilled manpower is needed for the assembling process.

d. It can make structural damage if the grade of the coupler will not equal to the reinforcement bars.

| Read Also: Pony Walls |