Table of Contents

Highway pavement is an essential component of the overall transportation system providing access to various parts of the world and facilitating the movement of people and goods.

✓ Due to its immense importance, it must be well maintained and promptly repaired. Otherwise, several problems may arise, ultimately leading to the failure of the pavement itself.

✓ Pavement failure may occur due to various factors such as excessive vehicular stress, sunlight exposure, water intrusion, unequal expansion and contraction due to seasonal changes, etc.

A. Types of Pavement Failure

Some of the types of pavement failure are:

1. Cracking

✓ Cracking is one of the most common types of pavement failure. The nature of the crack itself is fast spreading.

✓ Cracking is usually caused by improper material mix during construction and settling of the subgrade or base during operation.

✓ Several cracks in the pavement are:

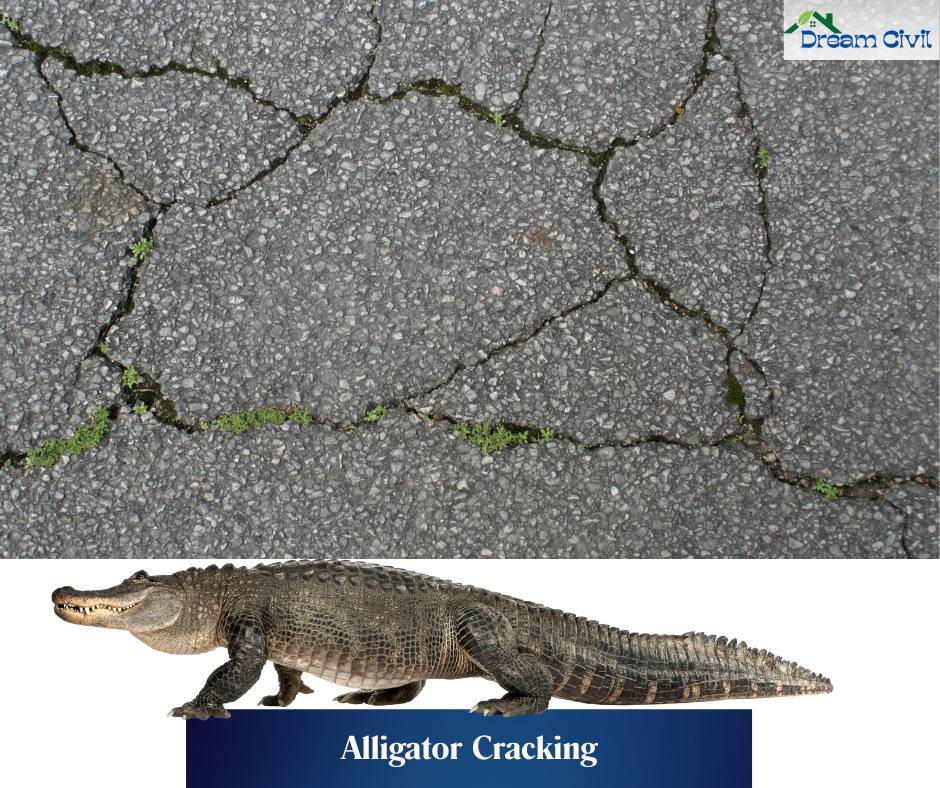

i. Alligator Cracking

Alligator cracking is the cracking that is associated with load and structural distress.

These cracks are extensively found at intersections where the vehicles are stopped for a relatively long period because these cracks start to form when the subgrade and base compress due to the excessive imposed wheel load.

a. Causes of Alligator Cracking in Flexible Pavement

1. Weakness in base, surface or sub-grade

2. Thinning of a surface course or base course

3. Poor Drainage

4. Excessive vehicular loads

5. Vehicle stopped for a relatively long period

b. Repair of Alligator Cracking in Flexible Pavement

a. Determine the primary source of the problem and the best way to repair it.

b. The crack filler is applied if a problem is seen on the surface course.

b. If failure is due to weakening of the base or sub-base course, cut the affected pavement area into rectangular or square shapes. Then, patch it like a pothole.

c. Causes of Alligator Cracking in Rigid Pavement

a. Weakening of base

b. Poor drainage

c. Poor quality material mix or use.

d. Repair of Alligator Cracking in Rigid Pavement

1. Full Depth Patching

It is a widely used method for treating alligator cracks in rigid pavements and restoring the structural stability and rideability of the pavements.

It includes the following series of steps:

a. Defining repair boundaries

The area’s boundary to be repaired must be first defined by surveying the region.

b. Sawing old concrete

Full-depth saw cuts facilitate the separation of damaged concrete from the adjacent concrete with minimal damage.

c. Removing old concrete

Concrete removal can be carried out either by lift out or break up. Lifting sawed concrete is faster, requires less labor, and doesn’t cause any significant damage to the adjacent layers.

In some cases, lifting concrete can be risky, and in such a situation, the deteriorated concrete is broken into smaller fragments and removed by backhoe or hand tools.

d. Preparing the patch area

After removing old concrete, the area to be patched is prepared. The area must be pumped out and cleaned correctly if it contains water.

e. Placing and Finishing new concrete

The new concrete is usually placed by ready-mix trucks or mobile batch vehicles. Concrete must be evenly distributed and spread. Using the finishing tools, the placed concrete is finished.

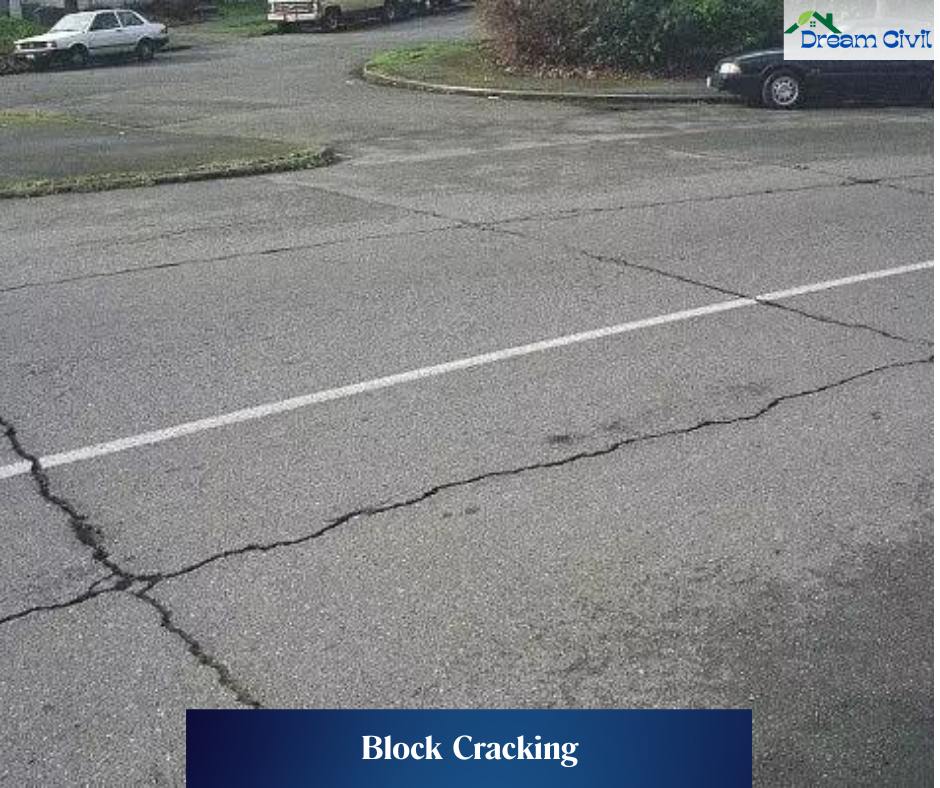

ii. Block Cracking

Block cracking is another cracking seen on highway pavements that forms a box-like crack on the surface.

This cracking is associated with the unusual expansion and contraction of concrete in rigid pavement and due to improper mixing or aging of asphalt or poor quality asphalt in flexible pavement.

Block cracking is mainly caused by shrinkage of the asphalt or concrete and daily temperature cycling, and it is not load-associated.

a. Causes of Block Cracking in Flexible Pavement

1. Use of improper mix

2. Fine aggregates mixed with low-penetration asphalt

3. Poor asphalt binder

4. Ageing of asphalt

5. Temperature cycling

b. Repairing of Block Cracking in Flexible Pavement

The quicker this cracking is detected, the easier it becomes to repair.

The sealing method of repair can be used for cracks less than ½ inch or less.

In severe cracks, an overlay must remove and replace the deteriorated pavement.

c. Causes of Block Cracking in Rigid Pavement

1. Use of improper mix

2. Lack of expansion joints in the pavement

3. Temperature cycling

d. Repair of Block Cracking in Rigid Pavement

If the crack is less than 1/2 inch, flexible fillers can be used to fill the cracks.

If the crack is more significant than 1/2 inch, the affected section of the road is removed and replaced by an overlay. Sometimes, the sections with metal plates can also be joined if traffic is low.

To eliminate the problem of block cracking, it is better to provide expansion joints at regular intervals.

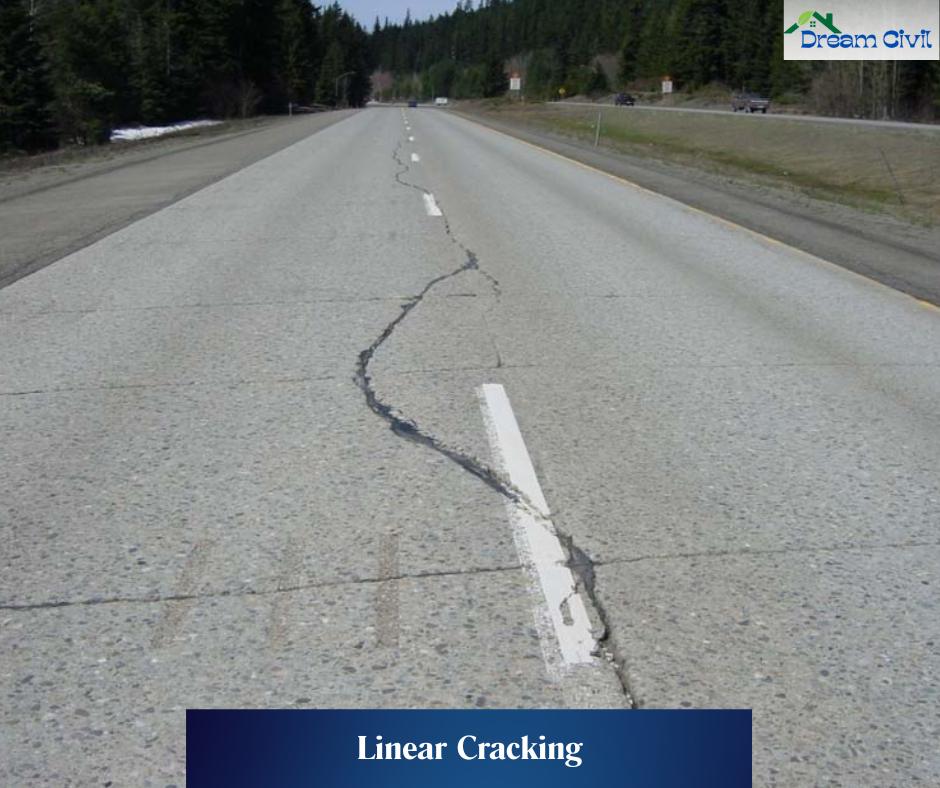

iii. Linear Cracking

Linear cracking is the common type of crack seen parallel to the roadway.

These are generally associated with fatigue and weak points of the pavement.

It is also known as longitudinal cracking.

a. Causes of Linear Cracking in Flexible Pavement

1. Pavement fatigue

2. Reflective cracking

3. Poor construction

b. Repair of Linear Cracking in Flexible Pavement

It can be repaired by sealing or replacement.

For less severe cracks, sealing of the cracks may be done.

For severe cracks, replacement by an overlay may be carried out.

c. Causes of Linear Cracking in Rigid Pavement

a. Heavy Traffic Loading

b. Joint Problems

c. Poor drainage of the water

d. Repair of Linear Cracking in Rigid Pavement

a. Crack sealing

b. Replacement of the slab

c. Joint repair

d. Overlaying of asphalt over cracks to control it

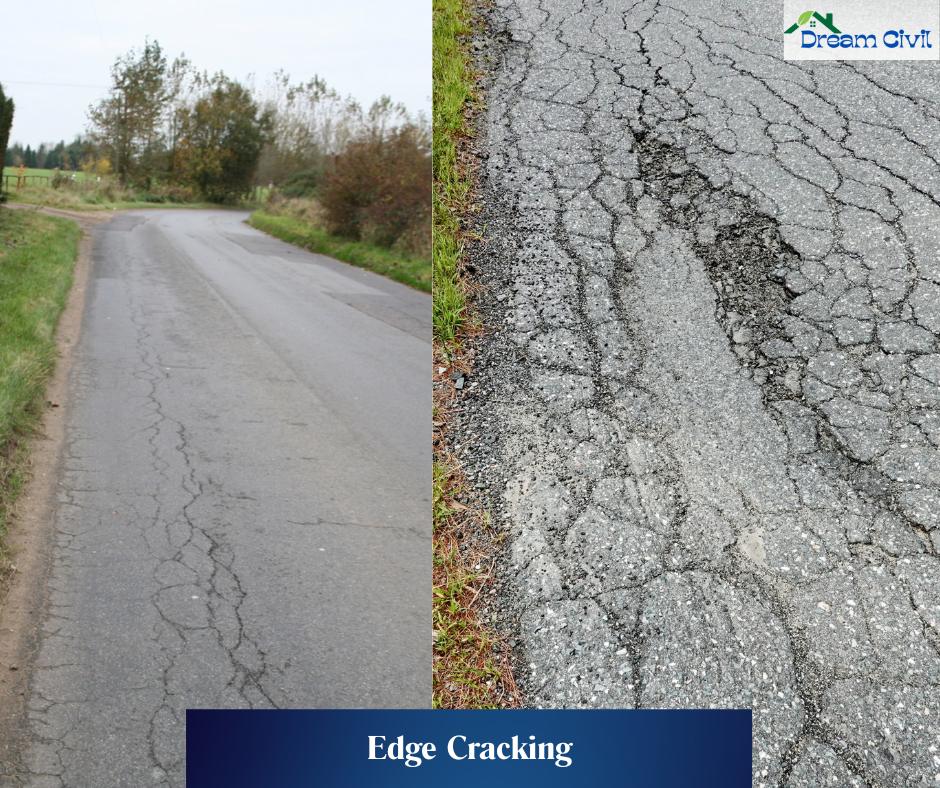

iv. Edge Cracking

Edge cracking is the type of crack that is usually formed at the edge of highway pavements.

These cracks are typically associated with the ingress of water in underlying layers.

a. Causes of Edge Cracking in Flexible Pavement

i. Lack of support at edges of pavement

ii. Poor drainage condition

iii. Heavy vegetation

iv. Heavy traffic alongside the edge of the pavement

b. Repair of Edge Cracking in Flexible Pavement

i. Crack of the sealing

ii. Reinforcing the edge

iii. Overlaying new asphalt layer

c. Causes of Edge Cracking in Rigid Pavement

i. Lack of sealant at joints

ii. Movement of the slab

iii. Improper drainage

d. Repair of Edge Cracking in Rigid Pavement

i. Crack Sealing

ii. Repairing of the joints

iii. Replacement of the slab

2. Potholes

Potholes are the type of flexible pavement failure that can be seen as small depressions on the pavement’s surface and can penetrate deep up to the base course.

These are generally associated with infiltration and result from alligator cracks if not appropriately treated.

Generally, severe alligator cracks left untreated create small fragments of pavement, and when vehicles ride over them, they result in potholes.

a. Causes of Potholes on Flexible Pavement

1. Pavement fatigue

2. Water infiltration

3. Freeze-thaw cycles

b. Repair of Flexible Pavements

1. Clean the area along the hole with the broom.

2. Trim it vertically to a regular geometrical shape like a square or rectangle.

3. Level the bottom of the hole and remove loose aggregate and foreign materials.

4. Apply a tack coat on the bottom and sides of the holes.

5. Now, apply the patching layer and compact it properly by taping or rolling.

6. If the hole depth exceeds 7.5cm, the Patching layer should be provided in 2 or more layers where each layer should be tamped or appropriately rolled.

c. Causes of Potholes in Rigid Pavement

1. Spalling of concrete

2. Heavy traffic loads

d. Repair of Potholes in Rigid Pavement

a. Defining repair boundaries:

The area to be repaired must be first defined by surveying the region.

b. Sawing old concrete:

Using full-depth saw cuts, the damaged area is first isolated from the remaining area.

Full-depth saw cuts facilitate the separation of damaged concrete from the adjacent concrete with minimal damage.

c. Removing old concrete:

Concrete removal can be carried out either by lift out or break up.

Lifting of sawed concrete is faster, requires less labor, and doesn’t cause any significant damage to the adjacent layers.

In some cases, lifting concrete can be risky, and in such a situation, the deteriorated concrete is broken into smaller fragments and removed by backhoe or hand tools.

d. Preparing the patch area:

After removing old concrete, the area to be patched is prepared.

The area must be pumped out and cleaned properly if it contains water.

e. Placing and Finishing new concrete:

The new concrete is usually placed by ready-mix trucks or mobile batch vehicles.

Concrete must be evenly distributed and spread.

Using the finishing tools, the placed concrete is finished.

3. Depressions

✓ Depression indicates the area on the surface of pavements with a slightly lower elevation than the surrounding areas.

✓ They become prominently visible after rainfall due to the accumulation of water.

✓ These are also referred to as birdbaths.

a. Causes of Depression in Flexible Pavement

1. Uneven thickness of subsequent layers

2. Subgrade settlement

3. Foundation soil settlement

b. Repair of Depressions in Flexible Pavement

The asphalt surface has to be replaced in severe depressions, while the area may be patched for smaller depressions.

c. Causes of Depressions in Rigid Pavement

1. Erosion of base

2. Failure of the joints

d. Repair of Depressions in Rigid Pavement

1. Mudjacking

2. Replacement of the slab

3. Repair of the joint

4. Rutting

✓ Rutting is a type of pavement failure that results in channelized depressions, particularly in the wheel track of pavement.

✓ Two types of rutting may occur: pavement rutting and subgrade rutting.

✓ With time, the wheels of heavy vehicles start to compact the asphalt surface, forming ruts.

a. Causes of Rutting in Flexible Pavement

1. Lateral movement or consolidation of consecutive layers under traffic load

2. Insufficient layer thickness

3. Lack of compaction

4. Improper mix

4. Moisture infiltration

b. Repair of Rutting in Flexible Pavement

If minor rutting has occurred, the rut can be filled and provided with an overlay.

In severe rutting, the damaged area must be lifted and replaced by a new layer.

c. Causes of Rutting in Rigid Pavement

1. Weak subgrade

2. Poor construction joints

d. Repair of Rutting in Rigid Pavement

1. Slabjacking

2. Repairing of the Joints

5. Corrugation and Shoving

✓ Corrugations refer to the regular distresses in the form of ridges and valleys on the pavement’s surface.

✓ They run along the direction of the pavement itself and are usually less than 5 feet.

✓ Similar distresses that run perpendicular to the traffic are known as shoving.

a. Causes of Corrugation and Shoving in Flexible Pavement

1. Weak granular base

2. Excessive fine aggregate

3. Excessively rounded aggregate

4. Extensively soft asphalt

b. Repair of Corrugation and Shoving in Flexible Pavement

It may be repaired by partial or full-depth patchwork, as in the case of alligator cracking.

c. Causes of Corrugation and Shoving in Rigid Pavement

1. Excessive load

2. Poor subgrade support

3. Inadequate slab thickness

4. Joint deterioration

d. Repair of Corrugation and Shoving in Rigid Pavement

1. Slab replacement

2. Joint sealing

3. Diamond grinding

6. Ravelling

✓ This failure is commonly seen only in flexible pavement, not rigid pavement.

✓ The type of pavement failure occurs due to continuous water ingress, thereby causing degradation of the topmost asphalt layer.

✓ As raveling progresses, the aggregate particles separate from the surface and leave eroded-like patches on the pavement.

a. Causes of Ravelling in Flexible Pavement

1. Excessively porous asphalt

2. The untimely placing of asphalt

b. Repair of Ravelling in Flexible Pavement

A thin hot-mix overlay may be provided. Sealing of the affected areas may also be effective.

( As this failure is not seen in rigid pavement, we have not included it. )

Read Also: Flexible Pavement