Table of Contents

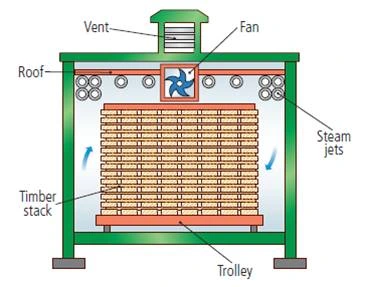

In kiln seasoning of timber; the timber is seasoned under controlled temperature and humidity conditions with proper air circulation and ventilation system.

✔ The temperature rise should be such that the timber retains the original strength and elastic properties. The required humidity level is maintained to avoid warping and cracking.

✔ The drying of timber at a uniform rate is well maintained by circulating air.

✔ The ventilation is provided to avoid overheating and excessive humidity.

The timber, inside the hot chamber, on the trolley is kept under controlled conditions for about a fortnight or so depending upon the initial water contents and the required moisture level.

The quality of wood obtained by this method is inferior as compared to the one seasoned by the natural methods.

1. Following points are worth noting

a. The wood may, if desired, be brought to the “bone-dry” state with almost no moisture.

It is not usual to carry the drying so far because such dry wood would re-gain moisture from the atmosphere.

Timber for framework should be seasoned to about 15% moisture content and for leaves of door/window shutters, the moisture content of timber should be kept between 10 to 12%.

b. The operation of the kiln requires careful control of the temperature and humidity of the air surrounding the wood at all stages of the operation.

The aim is to lower the moisture content of the wood to the required amount without causing the pieces to wrap or check and without leaving any residual strains in the wood.

c. If the drying continues too rapidly, cracks will form.

Even with careful work, when the center of the piece does become dry and shrinks, unequal stresses are set up, with the outer portion in compression and the inner tension.

This compression and hence increased hardness of the outer layers is named “casehardening”.

d. Casehardening may be minimized by expert’s dry-kiln practice and may be remedied by storage at a temperature higher than 700 deg. C under controlled conditions of humidity.

Under these conditions, wood becomes plastic enough to permit the strains to relieve themselves.

| Read More: Types of Seasoning of Timber |

2. Advantages of Kiln Seasoning of Timber

Following are the advantages of kiln seasoning of timber:

1. The moisture content can be reduced as per requirement.

2. The timber can be seasoned thoroughly well and in a short span of time under controlled conditions.

3. The timber seasoned by this method is less liable to shrinkage.

4. The wood can be used immediately as and when required.

5. The drying is controlled and there are practically no chances for the attack of fungi and insects.

6. The drying of different surfaces is even and uniform.

3. Disadvantages of Kiln Seasoning of Timber

Kiln seasoning of timber entails the following disadvantages:

1. This method is costly (though the space required is less).

2. It requires skilled labor.

3. Due to the process of drying being quick; continuous attention needs to be given to checking seasoning defects such as warping, internal cracks, surface cracks, and end- splits.

4. Difference Between Air Seasoning and Kiln Seasoning

Some differences between air seasoning of timber and kiln seasoning of timber are:

| Air seasoning | Kiln seasoning |

| 1. The air seasoning process is slow. | 1. The kiln seasoning process is quick. |

| 2. This seasoning is simple and economical. | 2. This seasoning is quite technical and expensive. |

| 3. Air seasoned timber is more amenable to attacks of insects and fungi. | 3. Kiln seasoned timber is less amenable to the attack of insects and fungi. |

| 4. This seasoning process requires more stacking space. | 4. This seasoning process requires less stacking space. |

| 5. It gives stronger timber. | 5. It gives a little weaker timber. |

| Read More: Types of Seasoning of Timber |