Table of Contents

In this article, we will discuss the gantry girder.

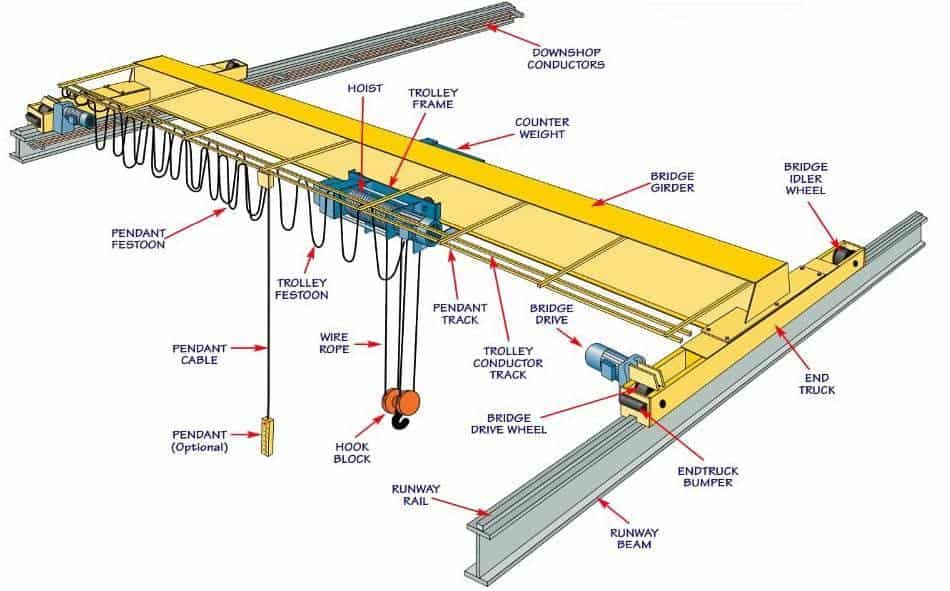

In a manufacturing plant, it is essential to keep an overhead traveling crane to transfer heavy parts of machines from one end to another end.

The motion of the load is 3D. The crane is required to raise huge mass vertically and horizontally, similarly, the crane with load is required to transport along the length of the shed. The cranes available in the market are either hand-or-electrically run. The crane moves on the rails which are at its ends. The rails used on a girder are known as gantry girders.

The gantry girder length over gantry columns. If the ability of the crane is average, the gantry girders rest on brackets connected to the roof column of the industrial shed.

Gantry girders or crane girders convey hand-run or electrically run overhead cranes to industrial buildings such as factories, workshops, steelworks, etc. to raise huge materials, equipment, etc., and to carry them from one end to the other end, within the building.

The gantry girders are girders that hold the loads that are carried through the moving wheels of the crane. The crane girder length from column to column does not own any lateral support at the moderate points except when a walkway is made at the top of the girder. The gantry girder lengths between the brackets attached to columns, may either be made of steel or reinforced concrete.

Thus the length of the gantry girder is the same as the center to center gaping of columns. The rails are attached to gantry girders. The trolley or crab, attached to the crane girder can move transversely along the crane girder. The trolley contains four wheels in it. The crane girder contains two wheels on each side and is able of transporting longitudinally on rails.

1. Types of Gantry Cranes

The following are gantry cranes types used in construction,

a. Full Gantry Crane Systems

b. Semi-Gantry Crane Systems

c. Portable Gantry Crane Systems

d. Adjustable Gantry Cranes

1.2. Types Of Load Acting On Gantry Girder

Gantry girder, having no lateral support in its length (laterally supported) has to resist the following loads,

a. Vertical Loads From Crane

b. Impact Load From Crane

c. Longitudinal Horizontal Force (Drag force)

d. Lateral Load (Surge Load)

1. Vertical Loads From Crane

A vertical load working over the gantry girder is the result of the crane girder and contains the self-weight of the crane, the self-weight of the crab, and the crane ability (the heavy load that can be lifted). To determine the reaction the highest wheel load is measured. It occurs when the crab is close to the gantry girder. The reaction from a crane girder and the self-weight of the rail should be equal to the assessment.

2. Impact Load From Crane

The stresses produced in gantry girders due to the overhead loads are more than those pretentious by slightly given loads. This is due to the forces produced by the unexpected use of brakes to smoothly transport loaded cranes acceleration, retardation, vibration, the feasible slip of slings, etc.

The steelwork which carries these fast working cranes must be weighty than the steelwork which holds the slow-moving cranes. With fast working electric overhead traveling (E.O.T) cranes, the stresses in the gantry girders are produced nearly at once, whereas, with slow transporting hand-operated cranes, the bending stresses in the girder are produced slightly from zero up to their highest values.

3. Longitudinal Horizontal Force (Drag Force)

This occurred due to the beginning and breaking off the crane girder transporting over the crane rails, as the crane girder transports longitudinally.

For example, in the direction of the gantry girder, the force is called Braking Force or Drag Force. This force is considered to be equal to 5% of the static wheel loads for the electrically run cranes or hand run cranes.

4. Lateral Load (Surge Load)

Lateral forces on crane girders may be convinced by the,

A) Lateral forces are caused due to the sudden starting or stopping of the crab when moving over the crane girder.

In the longitudinal gantry girders, the frictional resistance of the rail is transferred into the crab girders and from it into the crosshead girders, hence, as point loads through the major wheels, into the top or compression flanges of the gantry girders.

The place of the huge wheels when ultimate lateral bending and shear occurs on the gantry girder will be equal to those when an ultimate vertical bending moment and shear occurs.

B) Lateral forces occur when the crane is pulling weights across the floor.

The crane is usually appropriate to pull weights across the floor. If the load is huge, it is attached on rollers, and transported on a timber plank track. The lateral thrust and pull on the compressive flanges of the gantry girders, so, result in a matter of guesses. The resisting forces are, mainly the friction of the many wheels moving upon the gantry rails.

Then the forces are provided by the flanges of the major wheels bearing against the gantry rails. The lateral thrust is used to work in the plane of the center of gravity of the upper flange. As it does at the rail level, it has a lever arm producing torque.

This short lever member and, therefore, the torque are neglected. No support is accepted to be provided by the lower or tensile flange in resisting lateral thrust. Nevertheless, should this be done, then the torque due to the thrust increases by the distance from the line of action of the thrust to the Neutral Axis?

2. Uses Of Gantry Girder

The uses of the gantry girder are as follows:

a. To know the behavior of gantry girders.

b. To determine the various loads working on the gantry girder.

c. To determine the maximum bending moment and maximum shear force presence in the girders.

d. Select the right cross-sections for gantry girders.

e. To prepare the best attachments.

3. Characteristics Of Gantry Girders

The characteristics of gantry girders are as follows:

a. The preparation of the gantry girder is a unique example of a laterally baseless beam.

b. It is loaded in addition to vertical loads and horizontal loads along and perpendicular to its axis.

c. Loads are dynamic and produce vibration.

d. The compression flange requires reproving observation.

4. Design Steps

1. Maximum Wheel Load

The first process is to calculate the maximum wheel load of the crane girder transmitted to the gantry girder.

Uniformly Distributed Load on crane girder = Total heaviness of crane girder/ length of crane girder

Concentrated load = weight raised by hook + heaviness of the trolley

This concentrated load is kept at the point of the minimum hook application and the maximum reaction of the crane girder is determined. At each end of the crane girder, there are two wheels.

Load on each wheel = Maximum reaction divided by 2.

This wheel load is raised by 25% for impact and then factored in.

2. Maximum B.M.

Uniformly Distributed Load on gantry girder = Self-weight of gantry girder + weight of rail section

For maximum Bending Moment, the wheel loads must be so kept that the C.G. of the two-wheel loads (R) and the wheel loads recline equidistant from the center of the span (C). The maximum Bending Moment will then occur under that wheel load which is nearer to the middle of the girder.

3. Maximum Shear Force

Uniformly Distributed Load on gantry girder = self-weight of gantry girder + weight of rail section.

The Shear Force due to the wheel load is ultimate when one of the wheels is at the position of support.

Horizontal Force (Drag Force) Braking Force

Drag force is taken equal to 5% of the static wheel load on each gantry girder. This load is factored in.

Horizontal Transverse Force (Surge load)

Surge load = 10% of (weight lifted on hook + weight of crab) For one crane this load is transmitted by four wheels.

Surge load on each wheel = Total surge load divided by 4.

This load is factored in.

4. Section Selection For Gantry Girder

Normally, an I-section with a section is selected, through an I-section with a plate at the top flange may be utilized for light cranes.

The following steps are considered.

Economic depth of girder = L /12

Width of flange = L /40 to L /30

Zp Needed= k x Mu/Fy = 1.40 Mu/Fy

The moment capacity for vertical loads must be around 40 to 50% higher (k = 1.4 to 1.5) than the moment due to vertical loads so that the section can withstand both horizontal and vertical moments carefully.

5. Determine the Izz, Iyy, and Zp of the trial section choose

6. Check for moment capacity.

Mdz= βbZpFy/ γmo

Md should be greater than Mu. The top flange should be tested for bending in both axes utilizing the interaction equation.

Mz/Mdz + My/ Mdfy ≤ 1

7. Check For Shear Capacity

Maximum Shear Force = Vz

0.6 Vd should be greater than Vz.

8. Check For Buckling Resistance

When the gantry girder is laterally not held, the design bending strength of the beam is provided by,

Md= βxZpxFbd

Md should be more than Mu.

9. Check For Local Buckling

At points of concentrated load, the web of the girder must be reviewed for local buckling and, if essential, load-carrying stiffeners must be kept to save local buckling of the web.

Bulking Resistance = ( b1 + n1) tw x fcd

10. Weld Design Required shear capacity of weld,

Weld is required to connect the section to the top flange of the T-beam.

qw = VAȳ / Iz

The capacity of 1 mm long weld. P= lw tt Fwd = 0.7s

For shop welding, = 1mm If P>…. Safe.

11. Check For Deflection

Maximum deflection at center for two-wheel loads,

δc = Wl3 / 6EI x [3a/4L – a3/ L3]

Permissible Deflection

For Electric overhead traveling crane up to 500 KN ability,

δper = L / 750

| Read Also: Machinery For Construction Industry |