Table of Contents

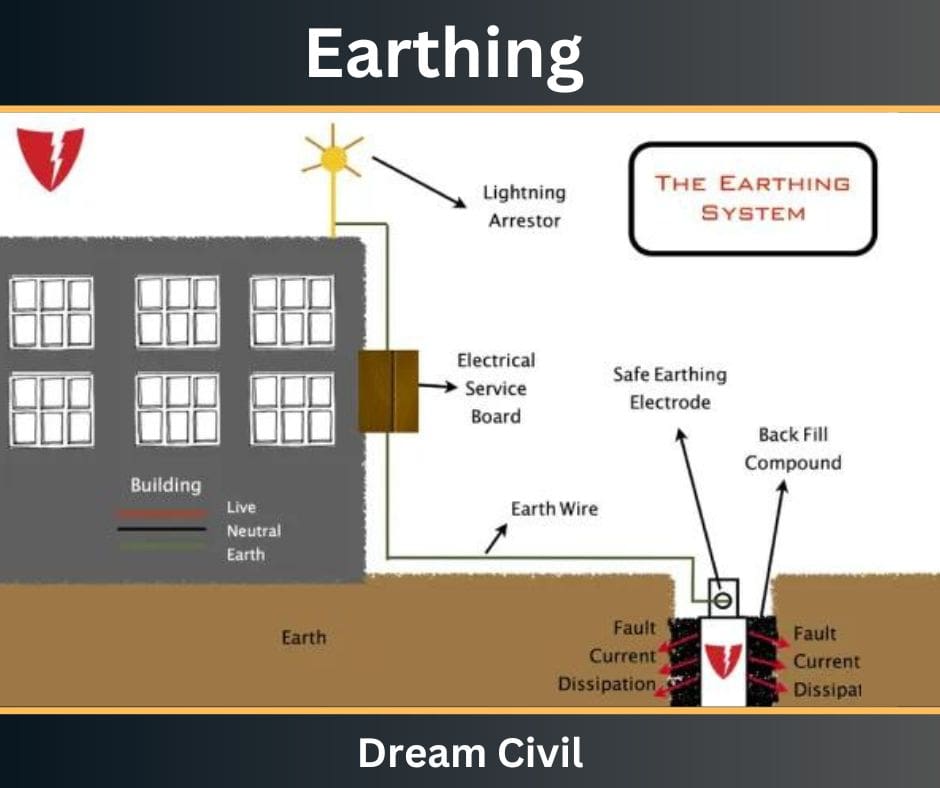

Earthing may be defined as the quick release of electrical energy by departing charges directly to the earth employing a low-resistance cable.

The various types of the earth are employed to connect the metallic parts of electrical devices or installations to the earth to control or reduce the chance of electrocution.

The various forms of earthing contain plate earthing systems, strip or wire earthing, rod earthing systems, and pipe earthing systems to ground, containing wire in buildings, homes, machinery, and electrical equipment.

1. Earthing

Electrical grounding is accomplished to provide security by combining the electrical appliance with the grounding/earthing system or electrodes positioned close to the soil or beneath ground level.

The flat iron riser-equipped electrode or earthing mat is established below the ground level. It helps in the connection of all non-current-carrying metallic components of the equipment.

The fault current from the equipment departs via the earthing system whenever an overload current is transferred through the equipment or when a system fault occurs due to the current.

The earth mat conductors support increasing the voltage by a quantity equal to the earth mat’s resistance multiplied by a ground fault. This shields the devices from overload or fault currents.

A building has 3 different wire types:

a. Live

b. Neutral

c. Earth

The bottom is connected to the covered metal plate in soil and live and neutral conduct electric current from the power plant. When in service, electric equipment like TVs, iron boxes, and refrigerators are directly connected to the earth wire.

As a result, these devices are protected from shocks or poor electrical supplies. Local earthing is taken out near the home’s electrical meter.

2. Types of Earthing

Electrical grounding is accomplished in housing, wiring, and electrical devices. The different types of electric earthing systems are:

a. Pipe Earthing

Pipe earthing is a standard way of linking to the earth’s electrical conductors by employing a steel pipe. Galvanized steel pipe of a diameter of 3.8 cm and a length of 2 meters is employed as an earth electrode in this method by being applied vertically in the ground.

The quantity of dampness in the soil and the strength of the current impact the size of the iron pipe that requires to be employed. The soil’s moisture will specify the maximum depth at which the steel pipe may be established.

The best and most practical method of earthing is pipe earthing, which is also effortlessly inexpensive.

b. Plate Earthing

For this form of electrical grounding, a plate formed of copper or galvanized iron is positioned vertically in the ground hole less than three meters beyond the ground. For a better practical electrical grounding system, one must preserve the earth’s moisture circumstances surrounding the plate earthing system.

This plate is connected to electrical wires to shift the electric charge within the earth.

c. Strip or Wire Earthing

In this condition of earthing, strip electrodes with the lowest cross-sectional area of 6.0 mm2 and the lowest depth of 0.5 m are seeded in horizontal ditches. If the electrodes are made of galvanized iron or steel, their cross-sectional area must not be smaller than 25 mm x 1.6 mm.

When covered in the ground soil, a conductor with the lowest length of 15 m would be given adequate earth resistance.

d. Rod Earthing

In this method of electrical grounding, a copper rod of a galvanized steel pipe is positioned vertically into the earth manually or with the help of a hammer to the desired value; the lengths of the embedded electrodes decrease the earth’s resistance.

The rod employed for this objective is buried in the dirt at a certain depth, securely redirecting the short-circuit electricity to the ground.

This electrical grounding method is appropriate for sandy areas and is also very budget-friendly.

3. Advantages

The advantages of electrical grounding are as follows:

a. The safest and most practical way to deliver safety for a building from electrocution is through electrical grounding.

b. The earth has no potential and is always taken as neutral. Balancing is performed because low resistance cable connects low equipment to the earth.

c. Metal may be employed in electrical systems without assuming its conductivity since it won’t transfer current if adequately earthed.

d. If adequate earthing protection is taken, a quick increase in voltage or overload has no negative effects on the object or the consumer.

e. It reduces the chances of fire hazards that might be caused by the current leakage.

4. Disadvantages

The disadvantages of Earthing are as follows:

a. It increases the construction cost.

b. Complexity of installation

c. Risk of corrosion.

d. Regular maintenance is needed.

5. References1. Content Filter & Authenticity Checking Team, Dream Civil International (Our team checks every content & detail to maintain quality.) |

Read Also: Mudjacking