Table of Contents

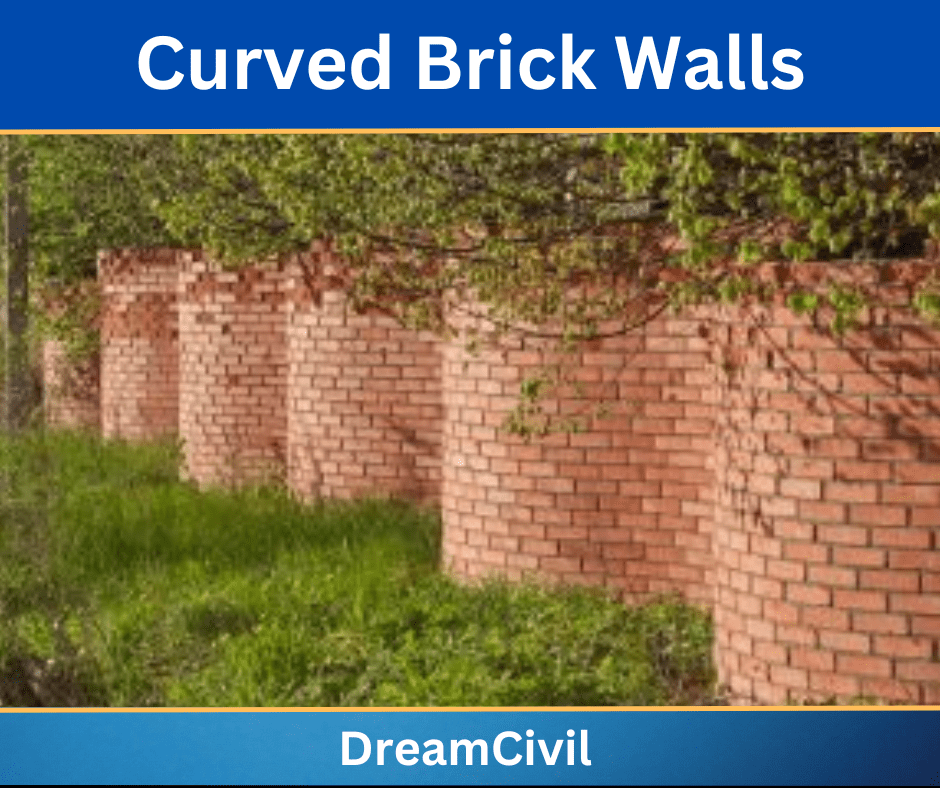

The walls built have a curve section mainly known as Curved Brick Walls.

The straight masonry brick wall can be rapidly and easily built with the utilization of threads and plumb bob.

But the curve section of the brick wall cannot be easily built as a straight section wall by the simple management of bricks. Spirit levels, gauges, and templates are utilized for curve brick wall construction.

And the mortar joints for straight masonry brick wall limits can be of 10 mm to 20 mm of regular thickness between the two joints of bricks. But for curved bricks joints can limit from 6 mm to 15 mm between the same two bricks due to the radial arrangement required to possess curvature.

The radius of curvature or degree of curvature affects the utilization of the brick size required to be useful and also the types of bonding structure.

For long curve sections, the full bricks can be kept simply along with some radial management of joint gaps and bricks.

But for a higher degree of curvature walls, bricks must be broken into smaller units with the radially decreased structure providing a trapezoidal structure.

1. Construction Procedure of Curved Brick Walls

The construction procedure of curved brick walls is as follows:

a. The external curve of essential curvature is first kept out and then the internal is kept out by calculating the internal radius by decreasing the width of the wall on the external radius.

i.e Internal radius ( r ) = External radius ( R ) – Thickness of wall (W)

b. The bricks are managed along with the joint extent in the boundary of the drawn curve to check whether the bricks are required to be cut for small pieces of needed shapes or not for smooth curvature.

c. This depends on the principle that; the circle is a polygon with infinite numbers of sides or line segments. The polygon with more than 16 sides almost looks like a circle from far.

d. Then after that wished shapes of bricks are cut if needed. While maintaining bricks radially along with curvature the inner side between the brick might have a narrow extent for mortar joint formation.

e. So, the bricks are cut radially as much as possible, or simply the corner of bricks at the inner face are knocked out to form space for mortar.

f. The place for mortar can be also geometrically calculated, but the process is very accurate and only utilize for accurate work and theoretical calculation and are not best for the practical approach of manual construction.

g. After removing the initially laid brick without mortar and the required processing of brick, the mortar is initially laid to the drawn curve.

h. Then the bricks are laid over the mortar layer arranged in the required curvature as before along with the mortar joints. The level of bricks is checked along with spirit level and curvature using the templates.

i. The upraised bricks are struck with the back end of the trowel so that the mortar displaces and the required level is achieved.

j. After confirming the uniform level of the first laid bricklayer the mortar is overlaid over the layer.

k. The mortar should be serrated or form a rough structure with the help of a trowel before laying the bricks.

l. Then the bricks are placed over it. The brick can be of the same size and shape as in the first layer, so the need for estimating the size and shapes is done before this time.

m. During the laying, of the brick in the next layers great care should be taken so that no joints of the above layer coincide with joints on its adjacent layers.

n. This will help to prevent failure through the joint of the masonry wall during the application of loads over it. Also, each layer is checked for a level surface. Vertical and curvature are checked with the help of spirit level and templates.

o. The consecutive layers are similarly placed one above another along with checking of levels and curvature of brick alignment.

p. The wall must be constructed up to 100 cm – 150 cm at a time and remaining work must be carried out only after drying of mortar.

2. Uses of Curved Brick Walls

The uses of curve brick are as follows:

a. It is used to increase the aesthetic beauty of the structure.

b. It is used to make construction cheap.

c. It is used where there is a lack of bricks.

d. It is used to save cost and time.

4. Advantages of Curved Brick Walls

The advantages of curved brick walls are as follows:

a. The ability to resist wind and compression loads.

b. It increases the aesthetic beauty of the wall.

3. It provides good stability.

4. Needs less amount of brick than straight walls.

5. Only one layer of brick is enough as it provides good stability.

6. No need for buttressing.

5. Disadvantages of Curved Brick Walls

The disadvantages of Curved Brick Walls are as follows:

a. Skilled Manpower is needed.

b. Maintenance may be costly.

6. References1. Content Filter & Authenticity Checking Team, Dream Civil International (Our team checks every content & detail to maintain quality.) |

| Read Also: Recycled Concrete Aggregate |