Table of Contents

✔ Safety equipment and tools protect lives, boost productivity, and reduce financial losses.

✔ It is essential to consider safety measures during construction projects. Safety equipment and tools not only protect laborers but can save lives as well.

✔ Workers should wear skin and body protective equipment to reduce chances of injuries and accidents caused by:

a. Falling objects

b. Falling from heights

c. Extreme temperatures

d. Radiation

e. Flames and sparks

f. Toxic chemicals

g. Sharp materials

✔ PPE stands for Personal Protective Equipment. Items such as gloves and earplugs are PPE. This is the equipment that protects you against hazards in the workplace. However, it can’t protect you if worn incorrectly or if you choose not to wear it.

| Read Also: Septic Tank |

A. 15+ Safety Equipment and Tools in Construction

✔ Here is the safety equipment that is used in the construction field.

| Name | Image | Use |

| 1. Protective Gloves |  | Protect our hands from infection, cuts, abrasion, and chemical contamination. |

| 2. Hearing Protection (earplugs or earmuffs) |  | Decrease the risk of hearing damage from excessive noise. |

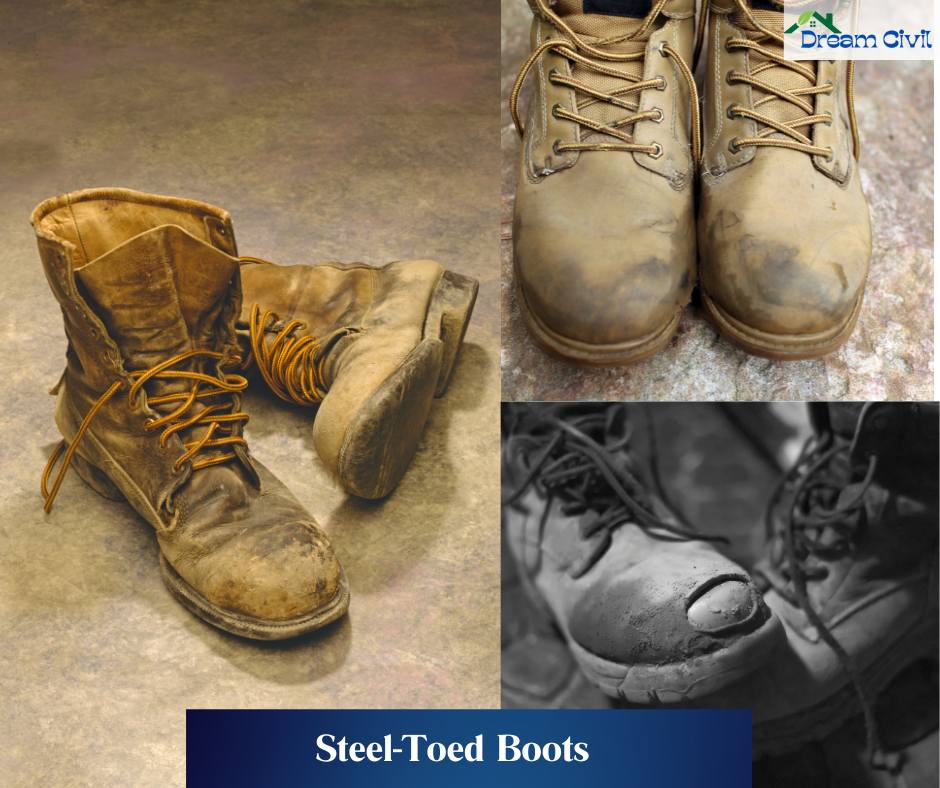

| 3. Foot Protection ( Boot ) |  | Protect foot from concrete, chemicals, mud, falling objects, etc. |

| 4. Reflective Gear |

| Provides signal of the presence of the user in places and events. |

| 5. Protective Glass |

| Protect eyes from dust, chemicals, and other harmful radiations. |

| 6. Respiratory protection ( Mask ) |  | Protect lungs from harmful dust, fogs, smoke, mists, gases, vapors, and sprays. |

| 7. Fall Protection |  | Protect workers from falling or, in the situations they do fall, to protect them without causing severe injury. |

| 8. Protective clothes |  | Protects the wearer from injury due to blunt impacts, electrical hazards, heat, and chemicals. |

| 9. Full face shields |  | Protect your eyes, as well as the rest of your face. |

| 10. Construction Helmet |  | Protect the head from injury due to falling materials. |

| 11. Safety Harness |  | To protect the workers from injury or death from falling |

| 12. Fire Protection ( Automatic fire control system) |  | Used to control fire. |

| 13. Safety Net |  | Provides safety for workers from falling on the ground floor. |

| 14. Fire Extinguisher |  | They are used to control fire. |

| 15. Safety Cone |  | Provide a brief reminder to pedestrians or motorists to proceed with extra caution. |

| 16. Caution Board |  | Provide gear warning to the operator in a hazardous situation that may cause minor or moderate injury. |

| 17. Knee pads |  | Protect them against impact injury from falling to the ground. |

C. Personal Protective Equipment (PPE)

a. Head Protection – Safety Helmets ( Hard Hats )

✔ Safety helmets are typically worn to protect the head from falling objects or impact with other items.

Purpose

✔ The primary purpose of hard hats is to protect the head, and the secondary purpose is to identify the individual and their role based on color coding.

Properties of a Safety Helmet

✔ Safety helmets should have the following desirable properties:

a. Shock Resistance: The helmet should be able to resist the shocks so that the head and brain remain safe.

b. Penetration Resistance: The helmet should be able to resist penetration.

c. Water Resistance: The helmet should be able to resist water.

d. Flammability Resistance: The helmet should be able to resist the flames.

e. Heat Resistance: Helmet would be able to resist the high heat.

f. Electrical Resistance: The helmet should be able to resist the electrical current.

Helmet Color Code

a. White Helmets: Managers, Engineers, Supervisors and Foremen

b. Yellow Helmet: Labors

c. Blue Helmet: Electricians, Carpenters, and other technical operators apart from civil work

d. Green Helmet: Safety Officers or Safety Inspectors

e. Orange Helmet: Road Crews, Visitors, or New Employees

f. Brown Helmet: Welders and other workers with high heat applications

g. Red Helmet: Fire Fighters

h. Grey Helmet: Site Visitors

b. Eye Protection – Safety Glasses

✔ Safety glasses, also known as protective eyewear, are used to protect the eye from dust and chemicals.

Use

✔ Used by construction workers, lab technicians, welders, and more for eye protection from dust, chemicals, and several impacts or injuries on the eye.

Importance

a. Preventing eye injuries

b. To resist impact on eyes

c. Protection of the eye from Chemical Splash

d. Protection of the eye from UV

c. High-Visibility Clothing

✔ High-visibility clothing is worn in low-visibility environments like construction sites, roads, etc.

Importance

✔ It improves the wearer’s visibility and helps in the prevention of accidents.

d. Hearing Protection – Earplugs and Earmuffs

Earplugs:

- Use: Inserted into the ear canal to block or diminish the entry of sound waves.

- Importance: Safeguards hearing in environments with elevated noise levels, such as concerts, construction sites, and during sleep. Acts as a preventive measure against potential harm from prolonged exposure to loud noises.

Earmuffs:

- Use: Surround the entire ear to obstruct or dampen external sounds effectively.

- Importance: Valuable for reducing overall noise exposure, frequently utilized in industrial settings, shooting ranges, and for general auditory protection in loud surroundings.

e. Respiratory Protection – Dust Masks and Respirators

Dust Masks:

- Use: Worn over the nose and mouth to safeguard against inhaling dust, and other toxic and non-toxic particles.

- Importance: A necessity for tasks like woodworking, cleaning, or gardening, creating a straightforward shield against inhaling airborne particles during daily activities.

Respirators:

- Use: Crafted to provide superior protection compared to dust masks, filtering out finer particles and ensuring a secure seal against the face.

- Importance: Vital in environments with hazardous airborne substances, including construction sites, healthcare settings, or areas with air contaminants. Offers a more exhaustive defense against respiratory risks.

f. Hand Protection – Gloves

✔ In the course of our daily lives, our hands play an irreplaceable role, emphasizing the critical need to shield them from potential harm.

✔ Whether handling sharp objects, dealing with hazardous chemicals, or maintaining hygiene in sensitive environments, the selection of the right pair of gloves becomes paramount.

Types of Gloves

a. General Purpose Gloves:

Use: Tailored for everyday tasks, providing a reliable defense against cuts, abrasions, and dirt.

Importance: Offers fundamental protection for routine activities, effectively minimizing the risk of commonplace injuries.

b. Chemical-Resistant Gloves:

Use: Acts as a hard shield against hazardous chemicals, preventing direct skin contact and potential harm.

Importance: Vital in industries where constant exposure to chemicals is a prevailing risk, ensuring the utmost safety for hands.

c. Cut-Resistant Gloves:

Use: Precision-engineered to protect against sharp objects, significantly mitigating the risk of cuts.

Importance: Required in environments where the handling of sharp tools or materials is routine, guaranteeing the safety of workers.

d. Disposable Gloves:

Use: Functions as a tight barrier against contaminants in medical, food, and cleanliness-sensitive tasks.

Importance: Crucial for upholding hygiene standards in healthcare and food service, effectively preventing the spread of contaminants.

Importance of Gloves

a. Injury Prevention:

- Gloves act as a hard shield, systematically reducing the risk of cuts, chemical exposure, and various injuries during a spectrum of tasks.

b. Hygiene Control:

- Particularly critical in industries such as healthcare and food service, gloves serve as a frontline defense, preventing contamination and maintaining a sterile environment.

c. Specialized Protection:

- Tailored gloves offer a nuanced and specific defense against unique hazards, ensuring safety across a diverse array of work settings.

Tips for Effective Hand Protection

a. Task-Based Selection:

- Optimal protection is achieved by selecting gloves based on the nuanced requirements of specific tasks and associated hazards.

b. Proper Fit:

- Ensuring a snug and proper fit is imperative, not just for comfort but for maximal protection, as ill-fitting gloves can compromise overall safety.

c. Regular Inspection:

- Vigilant and routine glove inspection is key, with damaged gloves promptly replaced to maintain their effectiveness.

d. Hand Hygiene Practices:

- Adhering to recommended hand hygiene practices, especially when employing disposable gloves, is essential to prevent contamination and uphold overall safety standards.

g. Foot Protection – Steel-Toed Boots

Use: Steel-toed boots protect feet in industrial settings by providing a sturdy barrier against falling objects and crushing hazards.

Importance: Essential for workplace safety, steel-toed boots reduce the risk of serious foot injuries, ensuring the well-being of workers in various industries.

h. Fall Protection – Safety Harnesses and Lanyards

Use: Safety harnesses and lanyards are vital for preventing falls in elevated work areas, protecting workers, and minimizing the risk of severe injuries.

Importance: Essential for workplace safety, these tools secure individuals working at heights, decreasing the chances of accidents and fostering a safer work environment.

D. Advantages of Using Safety Equipment and Tools in Construction

Some of the advantages of using safety equipment and tools in construction are:

a. Improve Worker Protection

Proper utilization of safety equipment and tools helps improve the worker’s protection from accidents like falls, cuts, etc.

b. Increased Productivity

When workers feel safe, their confidence and productivity improve.

c. Cost Savings

Although the initial cost is high, it saves many costs from workplace injuries and medical expenses in the long run.

d. Enhanced Reputation

Reducing accidents due to the proper use of safety equipment and tools improves the company’s reputation.

e. Long-Term Health Benefits

Protection of the health of construction workers is ensured when adequate safety equipment and tools are utilized.

| Read More: Construction Tools List |

| Verified by: Er. Bipana Kshetri Puri |