Table of Contents

Stone masonry is the art of building stone units bonded together with mortar.

✔ Stone masonry is used in building foundations, retaining walls, arches, floors, walls & columns.

✔ Mostly, natural rocks are used in stone masonry. Natural rocks are cut and dressed into proper shape before use.

✔ Stone masonry is very strong & durable. The strength mainly depends upon the types of stones or the mortar used.

1. Materials Used in Stone Masonry

Materials used in stone masonry are:

a. Stones

Stones to be used in stone masonry should be hard, durable, tough, and free from cavities, sand holes, and cracks.

The stones should be selected based on the availability of stones and the importance of structure.

The commonly used stones in masonry are limestone, sandstone, granite, marble, laterite, etc.

b. Mortar

Cement and lime mortar are commonly used in this masonry.

The selection of mortar depends upon the strength required, the color of the stone, and loads coming from the structure.

2. General Principle in Stone Masonry

The following point should be considered while supervising the stone masonry.

~ The stone should be strong, tough, hard, and free from cracks and cavities.

~ Each stone should be well-wetted before use so that it does not absorb water from mortar.

~ The stone should be appropriately dressed according to the types of work.

~ Masonry works should be raised uniformly.

~ Broken stones should not be used for facing and backing.

~ Wall should be laid completely vertical.

~ Double scaffolding should be used if stone masonry is to be carried out at a higher level.

~ No tensile stress should be produced anywhere because the stone is weak in tensile strength.

3. Tools used in Stone Masonry

Some standard tools used in stone masonry are:

a. Spalling Hammer

b. Pick

c. Mallet

d. Iron Hammer

e. Chisel

f. Claw Tool

h. Gads

i. Saw

j. Pitching Tool

k. Jumpers

4. Recommendations For Type of Stone

| S.No | Purpose | Type of Stone to be used |

| 1. | Heavy Engineering works such as ducks, breakwaters, bridges, piers, etc., carry high pressure. | Fine-grained granite and gneisses. |

| 2. | Masonry work in an industrial area, exposed to smoke and chemical fumes. | Granite, compact sandstone, and quartzite. |

| 3. | General Building work | Limestone and sandstone |

| 4. | Facework of building | Marble, granite, and closed-grained sandstone. |

| 5. | Carvings and ornamental work | Marble, laterite, and soft sandstone. |

| 6. | Pavings, door sills, steps | Slate, sandstone, marble |

| 7. | Fire-resistant masonry | Compact stone. |

5. Types of Stone Masonry

1) Rubble masonry

✔ In this masonry, undressed or roughly dressed stones are utilized.

✔ This masonry has wide joints since stones of varying sizes are used.

✔ Rubble masonry may be out of the following types:

a. Random Rubble Masonry

Masonry constructed using undressed or partially dressed stones in a random order is called Random Rubble Masonry.

There are 2- types of random rubble masonry:

1. Uncoursed Random Rubble Masonry

This is the roughest and cheapest form of stone-walling.

In this type of masonry, the stones used are of widely different sizes.

Since the stones are not of uniform size and shape, greater care and integrity have to be exercised in arranging them to distribute the pressure over the maximum area adequately. At the same time, long continuous vertical joints are avoided.

Sound bond should be available both transversely as well as longitudinally. The liberal use of headers obtains a transverse bond.

Larger stones are selected for quoins and jambs to increase strength and a better appearance. This type of masonry is also known as uncoursed rubble masonry.

Some of the features of this masonry are:

a. It is the cheapest and roughest type of masonry.

b. It has a varying appearance.

c. Corners of stones are slightly knocked off before using.

d. To increase the strength of this masonry, large stones are used at corners and jambs.

e. “Through stone” is used in every square meter for joining faces and backing.

2. Built to courses: Random Rubble Masonry

The construction method is the same as above, except that the work is roughly leveled up to form courses varying from 30 to 45 cm thick.

All the courses are not of the same height.

For this type of masonry, quoins are built first, and a line (string) is stretched between the tops of quoins.

The intervening walling is then brought up to this level by using different sizes of stones.

The figure below shows the procedure in which the stone has been numbered in the order in which they are placed. This form of masonry is better than uncoursed random rubble masonry.

b. Squared Rubble Masonry

The type of rubble masonry in which face stones are squared on all joints and beds by dressing before laying is called Square Rubble Masonry.

There are three types of square rubble masonry, which are explained below:

a. UnCoursed Square Rubble Masonry

Square rubble masonry uses stones having straight beds and sides. The stones are usually squared and brought to a hammer-dressed or straight-cut finish.

In the uncoursed square rubble, also sometimes known as square-snecked rubble, the stones with straight edges and sides are available in different sizes (heights). They are arranged on the face in several irregular patterns.

A pleasing appearance can be achieved by using risers ( a large stone, usually a through stone), levelers (thinner stones), and sneck or check (small stone) in a pattern, having their depths in the ratio of 3: 2: 1 respectively.

Snecks are the characteristics of this construction type, hence the name. This prevents the occurrence of long continuous joints.

Note: L means Leveller. S means Sneck. R means Risers.

b. Square Rubble: Built to courses

This type of masonry also uses the same stones as uncoursed square rubble. But the work is level up to courses of varying depth. The courses are of different heights.

Each course may consist of quoins, jamb stones, bonders, and thoughts of the same height with smaller stones built in between them up to the height of the larger stones, to complete the course.

Note: T means larger stones.

c. Square rubble: Regular coursed

In this type of masonry, the wall consists of various courses of varying heights, but the height of stones in one particular course is the same.

When the height of the courses is equal, it is usually called coursed rubble masonry (CR masonry).

Some features of square rubble regular coursed masonry are:

a. It is a superior variety of rubble masonry.

b. Stones are squared on all joints and beds and laid in courses.

c. Stones are laid in courses of equal layers.

d. Joints are uniform.

c. Miscellaneous Types

a. Polygonal Walling (Polygonal Rubble Masonry)

In this type, the stones are hammer finished on the face to an irregular polygonal shape. These stones are bedded in position to show face joints running irregularly in all directions.

Two types of polygonal walling may be there.

The stones are roughly shaped in the first type, resulting in the only rough fitting. Such work is known as rough picked work.

In the second type, the faces of stones are more carefully formed to fit more closely. Such work is known as close-picked work.

b. Flint Walling (Flint Rubble Masonry)

The stones used in this masonry are flints or cobbles, which vary in width and thickness from 7.5 to 15 cm and in length from 15 to 30 cm. These are irregularly shaped nodules of silica. The stones are extremely hard. But they are brittle and, therefore, may break easily.

The face arrangement of the cobbles may be either coursed or uncoursed or built to courses.

The strength of the flint wall may be increased by introducing lacing courses of either thin long stones or bricks at a vertical interval of 1 to 2 meters.

d. Dry Rubble Masonry

The rubble masonry constructed without using mortar or other binding agents is called Dry Rubble Masonry.

Un-dressed or partially dressed stones are used in this masonry.

It is suitable for constructing walls of a height less than 6 m.

2) Ashlar Masonry

The stone masonry constructed using finely dressed stone blocks is called ashlar masonry.

✔ The stone blocks may be either square or rectangular shaped.

✔ The height of stone varies from 25 to 30 cm.

Some features of ashlar masonry are:

a. The courses are of uniform height.

b. All the joints of this masonry are regular, thin, and have a uniform thickness.

c. Ashlar masonry is mainly used in the construction of heavy structures, architectural buildings, high piers, and abutments of bridges.

✔ The height of blocks in each is kept equal, but keeping all the courses of the same height is not necessary. Ashlar masonry may be divided into the following categories:

a. Ashlar Fine Tooled

This is the most refined type of stone masonry work.

Each stone is cut to the regular and required size and shape to have all sides rectangular so that the stone gives perfectly horizontal and vertical joints with adjoining stones.

The beds, joints, and faces are chisel-dressed such that all waviness and unevenness are completely removed, and a reasonably smooth surface is obtained.

The face which remains exposed in the final work is so dressed that no point on the dressed face is more than 1 mm from a 600 mm long straight edge placed on the surface in any direction.

The top and bed are also so dressed that no point on the surface is more than 3 mm, from the straight edge.

The side surfaces to form the vertical joints are also depressed that no point on the surface is more than 6 mm from the straight edge.

The surfaces forming internal joints which are not visible are also so dressed that at no point in the surface is more than 10 mm from the straight edge.

All the angles and edges exposed in the final position are kept as true squares and free from chipplings. The thickness of courses is generally less than 15 cm. The width of the stone is not kept less than its height.

Headers and stretchers are laid alternatively in each course, or courses of headers and courses of stretchers may be laid alternatively, or they may be laid as otherwise directed.

The thickness of the mortar joint is finely pointed.

b. Ashlar Rough Tooled Masonry (Bastard Ashlar)

In this type of masonry, the beds and sides of each stone block are finely chisels dressed just in the same manner as for ashlar fine, but the exposed face is dressed by rough tooling.

A strip, about 25 mm wide and made utilizing a chisel, is provided around the perimeter of the roughly dressed faces of each stone.

When tested with a straight edge 600 mm in length, the rough tooled face should not show any point on the surface to vary by more than3 mm in any direction.

This type of masonry is also known as bastard masonry.

The size, angles, edges, etc., are maintained in order, similar to fine-dressed ashlar.

The thickness of the mortar joint should not be more than 6 mm.

| Read Also: Quarrying of stone. |

c. Ashlar Rock or Quarry Faced

In this type of masonry, the exp[osed surface face of the stone is not dressed but is kept to give rock facing. However, a strip of about 25 mm wide, made using a chisel, is provided around the perimeter of the exposed face of every stone.

The projections on the exposed face (Known as bushings) exceeding 80 mm in height are removed by light hammering. However, each stone block is maintained true to its size, with perfectly straight side faces and beds and rectangular.

This type of construction gives a massive appearance. The height of each block may vary from 15 cm to 30 cm. The thickness of the mortar joint may be up to 10 mm.

d. Ashlar Chamfered Masonry

This is a unique form of rock-faced ashlar masonry in which the strip provided around the perimeter of the exposed face is chamfered or beveled at an angle of 45º utilizing a chisel to a depth of 25 mm. Due to this, a groove is formed between adjacent blocks of stone.

Around this beveled strip, another strip of 15 cm is dressed with the help of a chisel. The space inside this strip is kept rock-faced except that a hammer removes large bushings over 80 mm projections.

e. Ashlar Block in Course Masonry

This type of masonry is intermediate between rubble masonry and ashlar masonry.

The faces of each stone are hammer-dressed, and the height of blocks is kept the same in any course though it is not necessary to keep the uniform height for all the courses.

The vertical joints are not as straight and fine as in ashlar masonry.

The depth of courses may vary from 15 to 30 cm.

This type of masonry is adopted in heavy works such as:

✔ Retaining walls

✔ Bridges

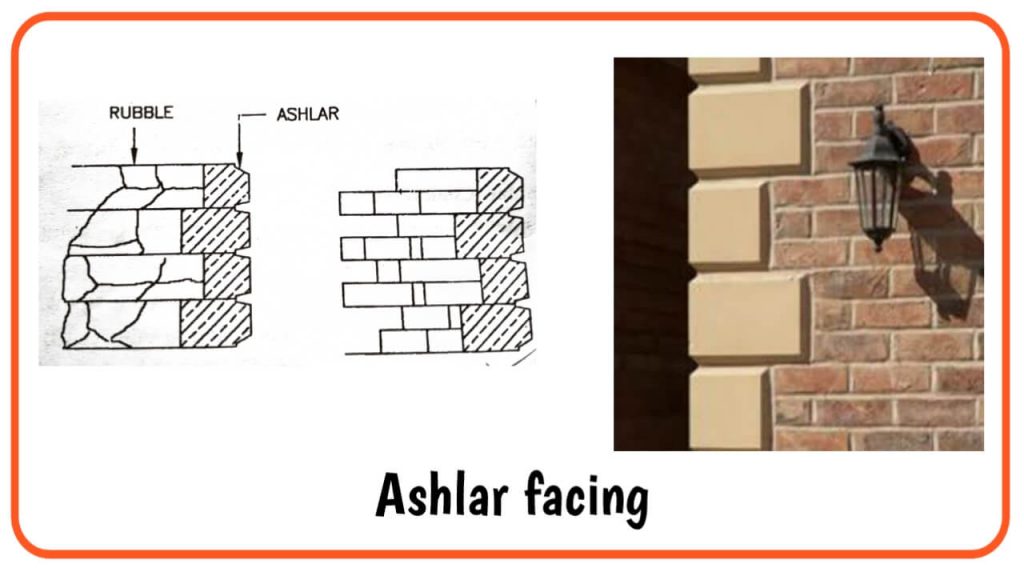

f. Ashlar Facing

Ashlar-facing masonry is provided along with brick or concrete block masonry to give a better appearance.

Each block’s sides and beds are appropriately dressed to make them accurate to shape.

The exposed faces of the stones are tough tooled and chamfered. The backing of the wall may be made in brick masonry.

| Read Also: Artificial Stones |