Table of Contents

Pipes basically refer to the hollow or tubular sections that are employed for the conveyance of fluids such as water from one place to another.

Pipes are an important type of unit used in various types of civil engineering constructions and work such as water supply distribution systems, sanitary and plumbing systems, conveyance systems, etc.

The various types of pipes used in civil engineering works have been further explained in brief below.

2. Types of Pipes

a. Kinds of Pipes Based on The Function

According to the purpose/function served by the pipes, they can be classified into the following categories:

1. Supply Pipes

The supply pipes are used to convey or supply water from the main distribution line of the water supply system to the households i.e. to the service areas.

In this regard, the supply pipes are also commonly referred to as service pipes.

Such pipes can be made up of copper, polythene, galvanized iron, or lead.

On the basis of the material of the pipe, supply pipes can be further classified into the following types:

i. Copper Pipes

~ Copper pipes are the type of supply pipes that are manufactured using copper as the chief constituent material.

~ They are highly desirable in cases where the groundwater table is relatively high. This is because copper pipes offer very high resistance to corrosion in comparison to other pipe materials.

~ Other desirable properties of copper pipes include the strength, ductility as well as capability to withstand high pressure and heavy flow.

~ They are extensively used both for domestic and industrial purposes.

~ Copper pipes can be further divided into two types on the basis of the pressure that the pipe will be subjected to. These types are as follows:

Fig: Copper Pipes

a. Heavy Gauge Copper Pipes

Heavy gauge copper pipes are the type of copper pipes that can withstand high pressure. Thus, these pipes are used where the pressure is quite high.

For example, high-gauge copper pipes are used in the main distribution line as the leading pipe.

b. Light Gauge Copper Pipes

Light gauge copper pipes are the type of copper pipes that cannot withstand high pressure. Thus, these pipes are used in cases where the pressure is not greater than 0.15 N/mm².

For example, light gauge copper pipes are used for domestic plumbing uses only.

Advantages of Copper Pipes

Some of the major advantages offered by the copper pipes can be listed as follows:

a. They are highly durable in nature.

b. They are capable of withstanding fluctuations in temperatures.

c. They have a life span of about 50 to 70 years.

d. They are capable of withstanding a pressure as high as 1000 psi (0.689476 N/mm²).

e. They are suitable both for cold and hot climatic conditions. Thus, can be installed even outdoors.

f. They also offer considerable resistance to corrosion from water.

g. They can be recycled.

h. The handling and installation of copper pipes are relatively easy as these pipes are light in weight.

i. They offer a significant degree of flexibility and can be transported easily.

j. They are also capable of resisting fire. This is because copper pipes have high thermal ratings.

k. The manufacturing of the copper pipes is environmentally compatible as it does not emit any dangerous gases and chemicals unlike polyethylene pipes and PVC pipes.

Disadvantages of Copper Pipes

Some of the disadvantages of copper pipes can be listed as follows:

a. Copper pipes and their plumbing are relatively expensive.

b. When copper pipes are used as supply pipes, a metallic taste may be imparted to the water being conveyed.

c. They do not offer good resistance to acidic water.

ii. Galvanized Iron Pipes

~ Galvanized iron pipes are also commonly referred to as GI pipes. They supply pipes that are primarily manufactured using galvanized iron as the chief constituent.

~ Basically, galvanized iron pipes have a protective coating of zinc so as to prevent the rusting of iron.

~ These pipes are extensively used in the rural water supply and distribution system for the conveyance of water.

~ They are more economical than copper pipes. Usually, galvanized iron pipes range in size from 15 mm to 150 mm.

Fig: GI Pipes

iii. Lead Pipes

~ Lead pipes are the type of supply pipes that are manufactured using lead as the major constituent.

~ They offer high resistance to corrosion, high flexibility, and a high hydraulic coefficient of flow.

Fig: Lead Pipes

~ They were extensively used in the water supply distribution system in the earlier days but are not much used these days. This is because the lead pipes may impart lead content to the water being conveyed which can lead to various harmful effects on human health.

According to the WHO reports the use of lead pipes in the service lines of the drinking water supply is one of the major contributors to lead contamination in water.

iv. Polythene Pipes (or Polyethylene Pipes)

~ Polythene pipes are the type of service pipes that essentially consists of plastic as the chief constituent.

~ They are extensively used as underground supply pipes for the conveyance of gas, oil, and water. Such pipes are also desirable for cold water service. Polythene pipes are light in weight and thus can be transported, installed as well as handled easily.

~ They are resistive to corrosion and bacterias.

~ The use of polythene pipes also eliminates the need for threading. However, one major drawback of polythene pipes is that these pipes cannot withstand very high temperatures.

2. Drain Pipes

~ The drain pipes are used for the conveyance of wastewater from the kitchen, bathrooms, industries, factories, etc to the point of disposal.

~ They are also commonly referred to as disposal pipes.

Fig: Drain Pipe

~ Depending upon the type of waste that the pipes convey, the drain pipes can be classified into the following:

a. Soil Pipes:

~ As the name itself implies; soil pipes are the type of drain pipe that carries night soil (human excreta) from the water closet of buildings and conveys it to the septic tank.

~ These pipes are always laid below the drinking water supply pipe and are connected only to the vent pipe.

~ Mostly, pipes having a diameter of 100 mm or more are used as soil pipes. In general practice, pipes made up of PVC are extensively used as soil pipes.

b. Wastewater Pipes:

~ Wastewater pipes are drain pipe that only carries wastewater (or greywater) from the kitchen, sinks, and washbasins.

~ They may be laid horizontally as well as vertically. Usually, pipes of diameter ranging from 30 mm to 50 mm are used as horizontal wastewater pipes. While pipes of diameter greater than 75mm are used as vertical wastewater pipes.

c. Rainwater Pipes:

~ Rainwater pipes carry the rainwater collected from the roofs, balconies, etc of the buildings during rainfall.

~ They are even used to convey the rainwater accumulated to the recharge zone or storage tanks for rainwater harvesting. Mostly, pipes having a diameter of 75 mm are used as rainwater pipes.

d. Anti-Siphonage Pipes:

~ Anti-siphonage pipes are used to prevent the backflow of drainage.

~ They are connected both to the wastewater pipes and the soil pipes.

~ The anti-siphonage pipes that are used to prevent the backflow of night soil and connected to the night soil pipes must have a diameter of 50 mm or more.

~ The anti-siphonage pipes that are used to prevent the backflow of wastewater and connected to the wastewater pipes must have a diameter of 40 mm or more.

e. Vent Pipes:

~ Vent pipes are used for facilitating ventilation inside the building.

~ They are used to convey foul gases away into the atmosphere.

~ They are normally placed higher than the roof level of the building. The vent level must be at least 1m above the roof level.

~ To facilitate the circulation of air, vent pipes are kept open both at the top and bottom. The diameter of the vent pipes must be 50 mm or more.

b.Types of Pipes Based on The Material of Manufacturing

Depending upon the material used for the manufacturing of pipes, they can be classified into the following types:

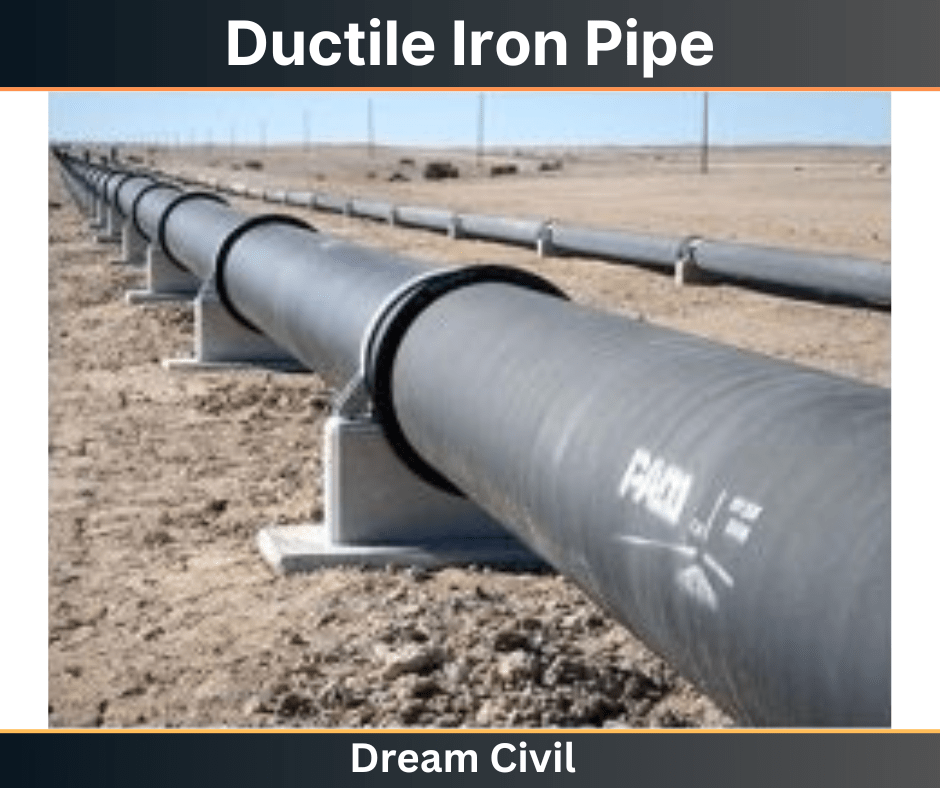

1. Ductile Iron Pipes

~ Ductile iron pipes are also commonly referred to as DI pipes.

~ They are extensively used for the piping systems in drinking water distribution systems.

~ They are an advancement to the cast iron pipes and have improved features.

~ They are used all over the world for the past hundred years.

Fig: Ductile Iron Pipe

Advantages of Ductile Iron Pipes

Ductile iron pipes offer the following advantages:

a. They have a life span of as long as a hundred years.

b. The need for maintenance is also relatively low.

c. They are quite economical as they are manufactured using recycled materials.

d. They offer a great degree of durability.

e. They have high strength and can resist heavy loads such as traffic loads.

f. They can be used even for high-pressure work.

g. They offer easy installation and are lighter than conventional iron pipes.

h. They have good ductility and the joining of such pipes is easier.

Disadvantages of Ductile Iron Pipes

Some of the disadvantages of ductile iron pipes can be listed as follows:

a. They are susceptible to damage due to corrosion.

b. They require both internal and external protective systems.

c. The polyethylene wrappings that are provided on top of the ductile iron pipes are prone to damage.

2. Concrete Pipes

~ Concrete pipes are manufactured using concrete.

~ They are extensively used for the conveyance and disposal of runoffs and drainage. Usually, precast concrete pipes of varying diameters are used.

~ They offer high resistance to fire hazards and environmental weathering agents.

Fig: Concrete Pipes

~ They are suitable for any type of sewer and drainage system.

~ They are also durable. However, one major disadvantage of concrete pipes is that these pipes are susceptible to damage by sulfates.

3. Cast Iron Pipes

~ Cast iron pipes are manufactured using iron as the chief material of manufacture.

~ The manufacture of cast iron pipes involves an extensive process of pouring the iron in the molten state into molds made up of sand.

~ Usually, cast iron pipes are used for small-scale drainage systems such as rainwater pipes in buildings.

4. PVC Pipes

~ PVC pipes are the type of pipes that are manufactured using plastic as the major manufacturing material.

~ They are extensively used both as supply pipes and drain pipes.

Fig: PVC Pipes

Advantages of PVC Pipes

Some of the advantages offered by PVC pipes can be listed as follows:

a. They are light in weight and thus can be handled easily.

b. The installation and transportation of PVC pipes are simple.

c. They offer a considerable degree of resistance to chemical attacks.

d. They are anti-corrosive in nature i.e. they are resistive to corrosion.

e. They have good elasticity and can be used for long-length piping systems.

f. They are economical.

Disadvantages of PVC Pipes

Some of the disadvantages of PVC pipes can be listed as follows:

a. They are susceptible to damage by cracking.

b. They cannot be used for high-temperature applications.

c. The manufacturing process of PVC pipes results in harmful emissions in the atmosphere.

5. Stoneware Pipes

~ Stoneware pipes are manufactured using ceramic or soft soil as the major manufacturing material.

~ The manufacturing process basically includes the burning of soft soil at extensively high temperatures in ceramic factories. Such pipes are used for the disposal of wastewater.

~ They can also be used for underground piping systems.

~ The major drawback of stoneware pipes is that these pipes are difficult to handle and install.

6. Asbestos Cement Pipes

~ Asbestos cement pipes are also commonly referred to as AC pipes.

~ They are manufactured using asbestos and cement as the major manufacturing materials.

~ Mostly, a mixture of Portland cement and asbestos fibers is used for the purpose.

~ They are used as distribution pipes and disposal pipes.

Advantages of Asbestos Cement Pipes

Some of the major advantages offered by Asbestos cement pipes can be listed as follows:

a. They can withstand both external and internal corrosion.

b. They can be manufactured using locally available materials and are thus economical.

Disadvantages of Asbestos Cement Pipes

Some of the disadvantages of asbestos cement pipes are as follows:

a. They are brittle in nature and thus the handling of such pipes is difficult.

b. They are susceptible to damage by sulfates.

c. They are not desirable in areas with large stones and boulders.

3. References1. Content Filter & Authenticity Checking Team, Dream Civil International (Our team checks every content & detail to maintain quality.) |

Read More: System of Sanitation