Table of Contents

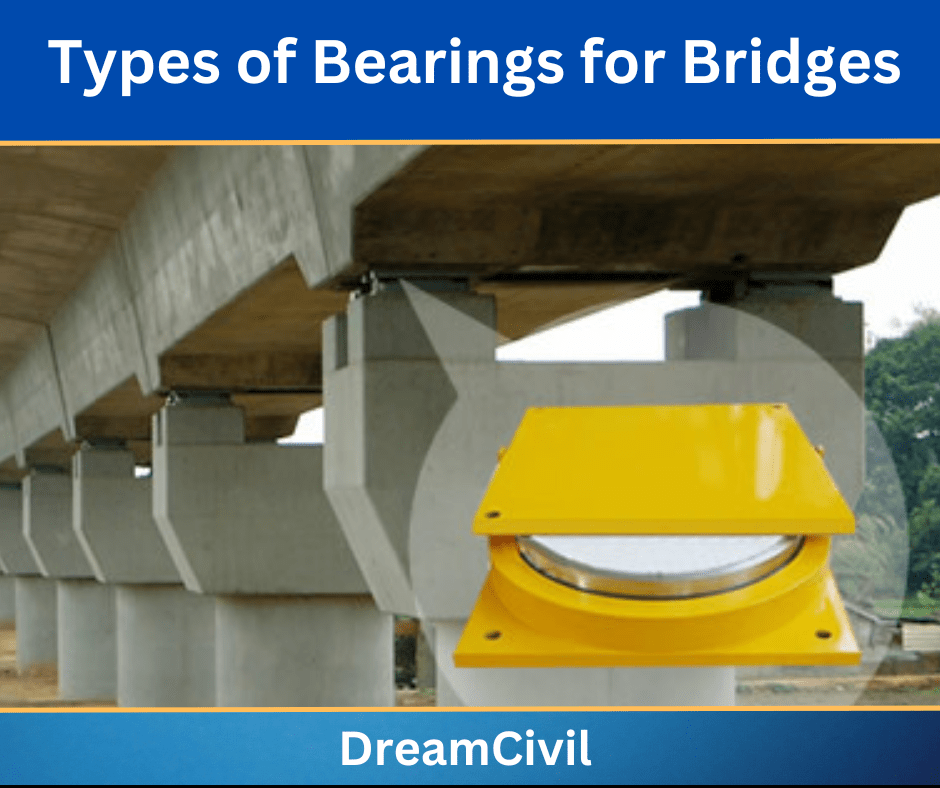

Bridge bearings are employed to transmit forces from the superstructure to the substructure, permitting different types of movements.

The following types of movements of the superstructure and types of bearings for bridges are mentioned below:

a. Translation Movements:

Displacements in both vertical and horizontal directions because of in-plane or out-of-plane forces like wind and self-weight.

b. Rotational Movements:

Cause due to moments.

1. Types of Bearings for Bridges

The types of bearings for bridges employed are made of the following types:

a. Pin Bearing

b. Roller Bearing

c. Rocker Bearing

d. Metal Sliding Bearings

e. Elastomeric Bearings

f. Curved Bearings

g. Curved Bearings

h. Disk Bearings

a. Pin Bearing

A pin bearing may be defined as a type of fixed bearing that holds rotations through the employ of steel.

Translational movements are not permitted.

The pin at the top is made of upper and lower semicircularly recessed surfaces with a solid circular pin set between them.

Mainly, there are caps at both edges of the pin to maintain the pin from sliding off the seats and to withstand uplift loads if needed.

The upper plate is attached to the sole plate by either bolting or welding. The lower curved plate lies on the masonry plate.

Rotational Movement is permitted.

Lateral and Translational Movements are Limited.

b. Roller Bearing

Roller bearings can be employed in the preparation of reinforced concrete and steel bridge structures.

There are two major configurations having a single roller bearing which is made of one roller kept between two plates and a multiple roller bearing which includes many rollers established between two plates.

The former can adjust both rotation and translation movement in the longitudinal direction and it is inexpensive to prepare but its vertical load capacity is restricted.

The latter can create room for translation movement only and rotation movement can be adjusted if rollers are connected with pin bearing.

Multiple roller bearings are costly and support greatly large vertical loads. Regular inspection and rehabilitation should be performed since roller bearings are exposed to corrosion and damage.

c. Rocker Bearing

A rocker stands an expansion bearing made of a curved surface at the bottom, which adjusts translational movement, and a fixed one at the top creates room for a rotation movement.

Both rocker and pin bearings are mostly used in steel bridge structures. Rocker and pin bearings should be regarded when the bridge movement is sufficiently known and described since such bearings can create room for both translational and rotational movements in one direction only.

These bearings are likely to suffer damage and corrosion, so it is essential to perform routine checks and maintenance.

d. Metal Sliding Bearings

The sliding bearing includes two metal plates, normally stainless-steel plates, that slide relative to each other and hence complete room for translational movement and lubricating material between them.

A friction force is developed in the sliding bearing and it is levied on the substructure, superstructure, and sliding bearing itself.

So, it may be needed to deliver lubricants such as polytetrafluoroethylene (PTFE) to decrease induced friction.

It is established by ASSHTO that sliding bearings cannot be employed unless the bridge span is more miniature than 15 m.

This is because sliding bearings cannot be fully employed if the bridge counter-rotation movement.

However, the span limitation for sliding bearing use can be ignored when it is employed in combination with other bearing types.

e. Elastomeric Bearings

It includes elastomers created from synthetic or natural rubber and can carry both translation and rotation movements through elastomer deformation.

The capability of elastomer to bear large vertical loads is because of reinforcement condition that controls the lateral bulging of elastomer.

There are a number of elastomeric bearing pads categorized relying on the types of reinforcements employed.

For example, steel-reinforced, plain, fiberglass-reinforced, and cotton duck-reinforced elastomeric bearing pads.

The strength and response of each type are various, steel reinforced elastomeric bearing is the most powerful one and plain elastomeric pad is the most vulnerable.

Elastomeric bearing is neither costly nor needs significant maintenance, which is why it is the preferred bearing type. It offers details of elastomeric bearing and its uses in bridge structure.

f. Pot Bearing

Pot bearing is made of an elastomeric disk confined in a pot, a steel piston that is properly tailored into the pot wall, and flat sealing rings which keep elastomeric inside the pot.

Pot bearing can support considerable vertical loads and it is commonly transferred through a steel piston to the elastomeric disc which is almost incompressible.

As far as the lateral load is concerned, it is transferred as the steel pistol moves toward the pot wall.

Translational movement is limited in pure pot bearing which is why PTFE is introduced to the sliding surface to make room for translation movement.

g. Curved Bearings

It is made of two curved plates that correspond to each other. If the curved bearing is cylindrical, then it only adjusts rotation movements.

However, both rotation and translational movements can be negotiated if the curved bearing is spherical.

The fact that both gravity loads and curved geometry induce lateral resistance against and therefore lateral movement would be limited, is why the polytetrafluoroethylene (PTFE) slider adheres to the bearings in order to create room for lateral movements.

h. Disk Bearings

Rotation movement is adjusted through the deformation of elastomer whereas the translation movement is thought through the use of a PTFE slider.

The employed elastomer should be sufficiently rigid to sustain vertical loads without causing considerable deformations and adequately flexible to authorize rotational movement.

Both vertical loads and lateral loads are backed by an elastomeric disk and metal ring in the center of the bearing respectively.

This was for the types of bearings for bridges.

2. References1. Content Filter & Authenticity Checking Team, Dream Civil International (Our team checks every content & detail to maintain quality.) |

Read Also: Contouring