Table of Contents

Slow San Filter is the earliest type of gravity filter developed by James Simpson in 1829 in England.

The filtration rate of a slow sand filter is usually one-twentieth (or less) of the rate of a rapid sand filter or pressure filter.

These filters require large areas of land and a correspondingly large quantity of filter media (sand) and base material (gravel).

Cleaning of the filter is done by surface scrapping which may involve a lot of labor. A slow sand filter is suitable when the availability of land, labor, and filter media is at a low cost.

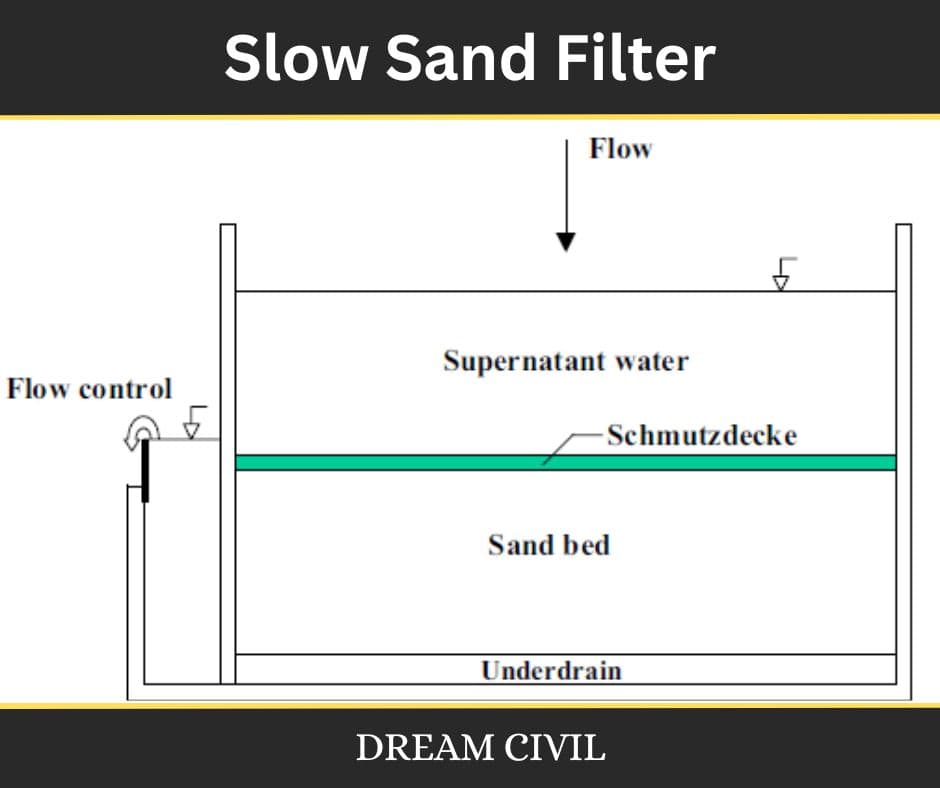

A distinguishing property of slow sand filters is the availability of a thin layer, called the schmutzdecke, which results on the surface of the sand bed and contains a large variety of biologically active microorganisms. It is a very simple and effective technique for purifying surface water.

It will remove practically all of the turbidity from the water as well as most of the pathogens without the addition of chemicals. If the turbidity of raw water is high then plain sedimentation would be required to reduce turbidity to some extent so that the fillers are not unduly loaded.

1. Parts of Slow Sand Filter

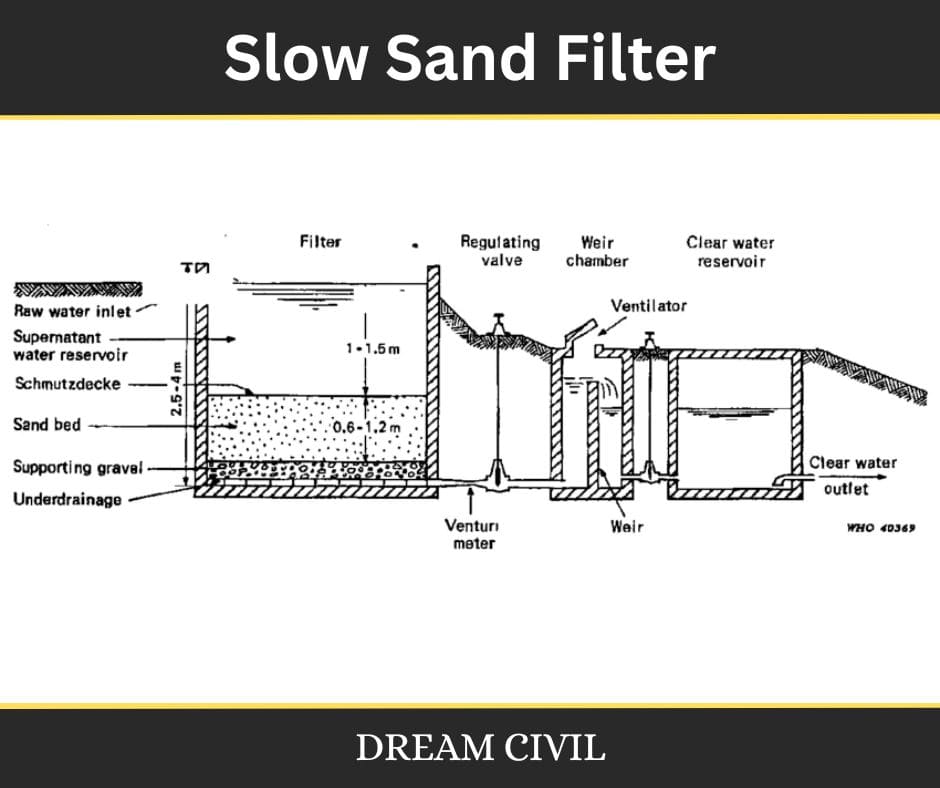

The slow sand filter and slow filter consist of the following parts mentioned below;

a. Enclosure tank

b. Filter media

c. Base material

d. Underdrainage system

e. Appurtenances

a. Enclosure tank

An open watertight rectangular tank constructed of brick masonry or stone masonry or concrete.

The tank hay depth of 2.5 to 3.5 m, surface area 50 to 1000 m2 or n depends upon the filtration rate which varies from 100 to lit/hr/m2.

The floor of the tank is provided at the cross Si of 1 in 100 to 200 towards the central drain.

b. Filter media

It consists of a sand layer of 90 to 110 cm thick with effective sizes of 0.25 to 0.35 mm (0.3 mm common) and uniformity coefficient (Cu) of 3 to 5, Finer the sand increases the removal efficiency of turbidity and bacteria but decreases filtration rate. The filter media (sand) should not contain Ca and Mg more than 2%.

c. Base material

The filter media is supported on the base material (gravel) of a 30 to 75 cm thick bed. The gravel bed is graded and it is laid in different layers each 15 cm thick. A typical section of the base material is indicated below.

d. Under Drainage System

Under drainage system supports the filter media and the base material and collects the filtered water and delivers it to the clean water reservoir. A central drain receives filter water from lateral drains. The lateral drains are placed at a distance of 2 to 3 m and ended about 50 to 80 cm from the walls of the tank.

e. Appurtenances

For efficient and proper functioning of filters, certain devices are installed during construction known as appurtenance, such as vertical air pipes, depth controlling devices, head loss, measuring devices, flow regulators, etc.

3. Working and Cleaning of Slow Sand Filter

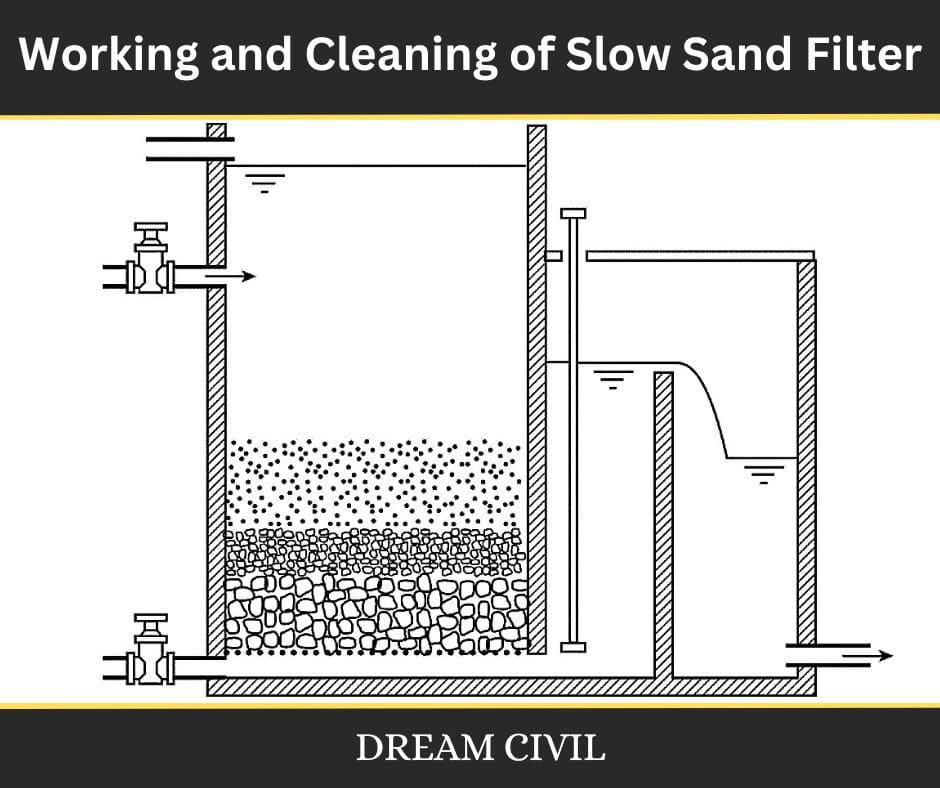

Water from the sedimentation tank is permitted to enter the filter through the inlet. The depth of water over the filter media is generally kept equal to the thickness of the layer of filter media.

The water percolates through filter media and during this water gets purified. The purified water is collected by underdrains and comes out from the outlet from where it is taken to a clear water storage reservoir.

A slow sand filter is operated up to 65 to 85% of the thickness of the sand bed. Cleaning of the filter requires after a period of 1 to 3 months. The top layer of filter media is scrapped or removed through a depth of 15 to 30 mm (25 mm commonly).

After cleaning the filter is operated at one-fifth of the normal rate for 12 to 15 hrs then the filtration rate is kept at one-third of the normal rate for 3 to 4 days, l this period the filter is operated at its normal rate.

Scrapping is done till the thickness of the filter media reaches 60 cm. When this stage is reached, filter media is replaced up to its original level.

4. Efficiency of Slow Sand Filter

The efficiency of the slow sand filter is as follows:

1. Bacteria removal efficiency of a slow sand filter is quite efficient i.e. it is about 98 to 99 % of the bacterial load from raw water. It can be achieved up to 99.9% when pretreatment is done.

2. It can remove turbidity to the extent of about 50 ppm.

3. 20 to 25 % of color can be removed.

4. Colloidal cannot be removed easily.

5. Advantages of Slow Sand Filter

The cost of construction is low, and its simplicity of design and operation means that slow sand filters can be built and used with limited technical supervision.

Little special pipework, equipment, or instrumentation is needed, and the labor required for maintenance can be unskilled as the major labor requirement is in cleaning the beds, which can be done by hand.

Imported materials and equipment are usually negligible and no chemicals are required. Likewise, power is not needed if a gravity head is available, and there are no moving parts or requirements for compressed air or high-pressure water.

Variations in raw water quality and temperature can be accommodated, provided turbidity does not become excessive, and overloading for short periods does no harm. Compared to rapid sand filtration, there is a net savings of water as large quantities of backwash water are not required.

| Read More: Sedimentation in Water Treatment |

6. Disadvantages of Slow Sand Filter

Slow sand filtration units require large land areas for plants treating large flows (about five times that of rapid sand filtration plants). Clogging may occur if the source water is excessive or if certain (filamentous) types of algae are present in the raw water. Pre-treatment with roughing filters or settling tanks may be necessary if such clogging occurs frequently.

Also, toxic contamination of the raw water may affect the biological surface layer (this could be a good indication of water source problems).

7. References1. Content Filter & Authenticity Checking Team, Dream Civil International (Our team checks every content & detail to maintain quality.) |

Read Also: Concrete Cutting Machine