Table of Contents

Scan line or discontinuity surveys are essential for estimating rock mass quality in rock mechanics and underground structures.

1. Scan Line Survey

This process involves scanning the outcropped rock surface and data collection for rock mass analysis. Scan line surveys are thus helpful for the preliminary design of structures supported on rocks.

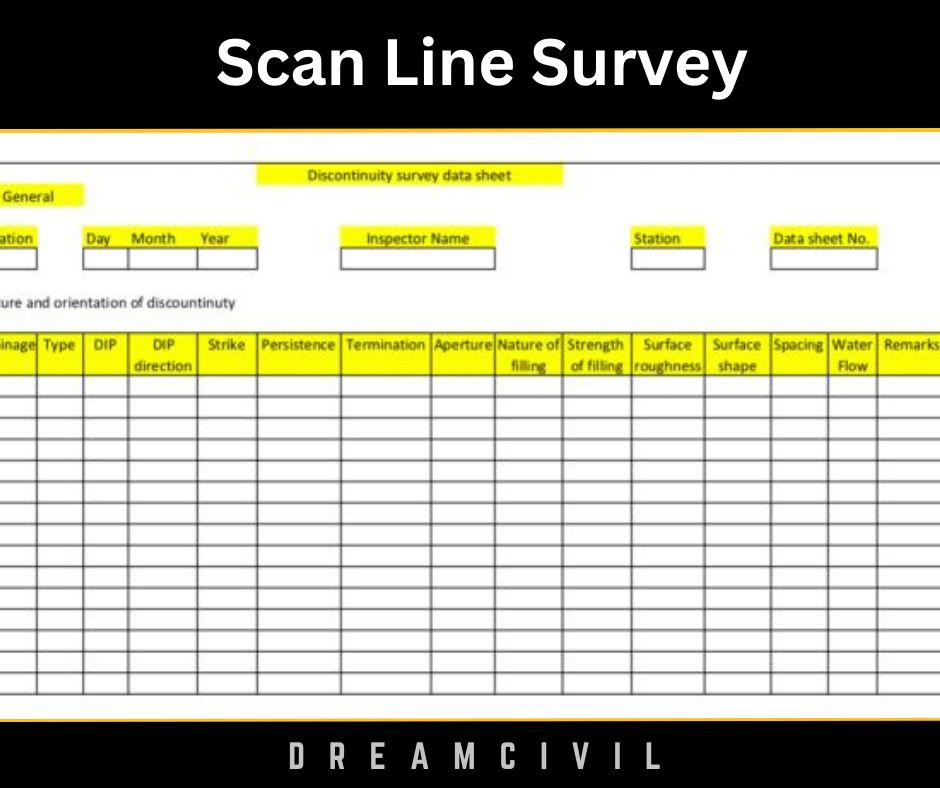

Also, this survey illustrates a horizontal line over the outcropped rock surface, and all discontinuity properties, such as spacing, orientation, persistence, aperture, etc., are examined. Meanwhile, all the properties are noted in the scan line survey datasheets.

After that, the collected data is researched comprehensively to choose the rock mass’s strength, deformability, and flow characteristics.

2. Evaluation of Rock Joint Properties

The scanline sampling technique can calculate a rock joint’s most significant aspects.

As an example, the scan line survey method contains the estimation of the following parameters:

a. Joint orientation

b. Spacing between joints

c. Joint Aperture

d. Joint persistence

e. Roughness characteristic of a joint

f. Joint filling

g. Strength of filling material

h. Water flow condition

Simultaneously, the above-mentioned parameters should be noted in the scan line survey datasheet while operating in the field. For this goal, a sample of scan line survey data is provided below:

a. Joint Orientation

Joint orientation is crucial in specifying the rock block’s stability, as the rock mass’s extreme deformation relies upon it.

Notably, the exposure of a particular joint set is determined by its dip, dip direction, and strike.

1. Dip

The dip may be defined as the angle of the discontinuity plane to the horizontal plane, ranging between 0-90 degrees.

2. Dip Direction

It is the direction of the dip angle and is commonly represented as N, NE, E, SE, S, etc.

3. Strike

It is the angle perpendicular to the dip angle, commonly lying between 0 to 360 degrees.

b. Spacing between Joints

Spacing is described as the perpendicular length between the discontinuities available. The joint spacing would be the mean spacing for a particular joint set, which contains the ‘n‘ number of discontinuities.

The spacing between joints generally prevents the flow of filled material and the mode by which the rock block fails. For example, the failure of closely spaced joints is controlled by circular mode (Type of rock failure).

The International Society for Rock Mechanics (ISRM) categorizes the joint spacing as displayed below:

| ISRM Suggested Description | Joint spacing (m) |

| Extremely close spacing | < 0.02 |

| Very close spacing | 0.02-0.06 |

| close spacing | 0.06-0.2 |

| Moderate spacing | 0.2-0.6 |

| Wide spacing | 0.6-2 |

| Very wide spacing | 2-6 |

| Extremely wide spacing | >6 |

c. Joint Aperture

The two discontinuities are usually not in complete contact, because of which a void between the two discontinuity surfaces. Therefore, the perpendicular distance between the gap of rock walls, divided by the adjoining rock blocks, is known as the Aperture.

A joint gap is supplied with air/water (open joint) or infill materials (filled joint).

The aperture is thereby determined from the width of a filled discontinuity. As an outcome, open or filled joints with extensive apertures have low shear strength.

Aperture affects the flow and permeability of the rock joints seriously, and the ISRM category for the aperture is displayed below:

| Aperture | Description | Features |

| < 0.1 mm? | Very tight | Closed features |

| 0.1 – 0.25 mm | Tight | Closed features |

| 0.25 – 0.5 mm | Partly open | Closed features |

| 0.5 – 2.5 mm | Open | Gapped features |

| 2.5 – 10 mm | Widely open | Gapped features |

| 1 – 10 cm | Very widely open | Open features |

| 10 – 100 cm | Extremely widely open | Open features |

| > 1 m | Cavernous | Open features |

d. Joint Persistence

Joint persistence is described as the discontinuity length and is calculated in meters. More straightforwardly, the trace length of discontinuity on the susceptible rock mass is known as persistence.

The shear strength of any discontinuity is hugely influenced by persistence. Hence, the sliding and slipping motion of rock obstructions along the discontinuity plane is also influenced by it.

The ISRM classification for persistence is as displayed below:

| ISRM Suggested Description | Surface Trace Length (m) |

| Very low persistence | < 1 |

| low persistence | 1-3 |

| Medium persistence | 3-10 |

| High persistence | 10-20 |

| Very high persistence | >20 |

e. Roughness Characteristics of Joint

Usually, the interface between the two attaching surfaces is rough or smooth. The aperture of the interface controls the requirement of the roughness of the surface.

Therefore, the joint roughness estimates the undulated interface surface close to the mean size of the joint plane.

Joint roughness influences the joint’s shear strength, and the discontinuity’s roughness governs the blocks’ displacement.

However, as material filling in the joint gains, the roughness of that joint decreases, thereby reducing the probability of sliding down the discontinuity.

On the other hand, the joint roughness is calculated by the undulation of the susceptible rock surface in the field.

Thus, each undulation should be organized on an arbitrary scale of one to nine. Each class of roughness is described as per the ISRM classification, which is displayed below:

| Class | ISRM Description |

| 1 | Rough or irregular, stepped |

| 2 | Smooth, stepped |

| 3 | Slickensided, stepped |

| 4 | Rough or irregular, undulating |

| 5 | Smooth, undulating |

| 6 | Slickensided, undulating |

| 7 | Rough or irregular, planar |

| 8 | Smooth, planar |

| 9 | Slickensided, planar |

f. Joint Filling

Two rock discontinuities are filled with identical filling materials, like calcite, chlorite, clay, sand, silt, quartz, pyrite, etc.

The shear strength properties of the joint alter depending on the properties of the filling material.

The manners of the filled discontinuities rely on various elements; where the primary ones are:

1. Mineralogy of filling material

2. Grading or particle size

3. Over-consolidation ratio

4. Water content

5. Permeability

6. Previous shear displacement

7. Wall roughness

g. Strength of Filling Material

The strength of the filling material is calculated by employing the rebound hammer device. While estimating the strength of the filling material, the device must be calibrated as per the location environment. Subsequently, the rebound hammer test should be finished.

The ISRM categorizes the filling material relying on the compressive strength, as tabulated below:

| S.No. | Compressive strength (MPa) | Classification |

| 1 | 0.025 | The filling material is a very soft clay |

| 2 | 0.025-0.05 | The filling material is a soft clay |

| 3 | 0.05-0.10 | The filling material is a firm clay |

| 4 | 0.10-0.25 | The filling material is a stiff clay |

| 5 | 0.25-0.50 | The filling material is a very stiff clay |

| 6 | >0.50 | The filling material is a hard clay |

| 7 | 0.25-1.0 | The filling material is a fragile rock |

| 8 | 1.0-5.0 | The filling material is a fragile rock |

| 9 | 5-25 | The filling material is a weak rock |

| 10 | 25-50 | The filling material is a medium-strong rock |

| 11 | 50-100 | The filling material is a strong rock |

| 12 | 100-250 | The filling material is a solid rock |

| 13 | >250 | The filling material is a solid rock |

h. Condition of Water Flow

ISRM recommends the following rating for the water discharge in joint discontinuity:

| S.No. | Description | Rating |

| 1 | Joint discontinuity is completely dry, and there is no evidence of water flow. | 0 |

| 2 | Joint discontinuity is completely dry, and there is evidence of water flow. | 1 |

| 3 | Joint discontinuity is damp, and there is no free flow of water | 2 |

| 4 | Joint discontinuity shows the free flow of water, but it is not continuous | 3 |

| 5 | Joint discontinuity shows the continuous free flow of water | 4 |

| 6 | The joint filling materials are consolidated, and no significant flow of water. | 5 |

| 7 | The joint filling materials are damp, and no free flow of water. | 6 |

| 8 | The joint filling materials are wet, and an occasional water flow is present. | 7 |

| 9 | The joint filling materials are wet and have a continuous flow of water. | 8 |

| 10 | The joint filling materials are entirely washed out with continuous water flow. | 9 |

This was for the Scan Line Survey.

3. References1. Content Filter & Authenticity Checking Team, Dream Civil International (Our team checks every content & detail to maintain quality.) |

Read Also: Bolt vs Screw