Table of Contents

In this article, we will discuss plum concrete.

| Summary Plum concrete may be defined as a normal concrete mix with large-size stones of up to 300mm as inert fillers. Aggregates exceeding 160mm are known as plums. The extended use of plum (boulders) saves PCC’s cost up to 30% and increases the apparent yield of concrete for a given amount of cement. |

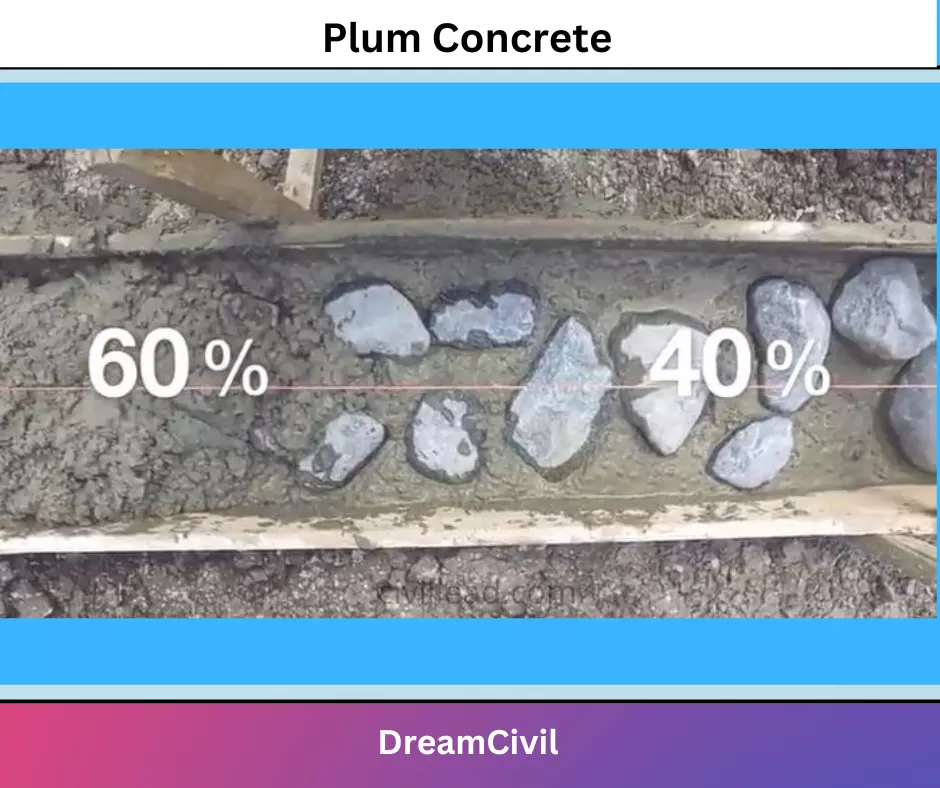

Far from reinforced or prestressed concrete, it is not backed with steel. The Plum Concrete mix ratio will be up to MI5, with the use of boulders up to 300 mm (60% concrete and 40% boulders). It is widely used as surface filler under the foundation where the surface is uneven and sloped.

1. Purpose of Plum Concrete

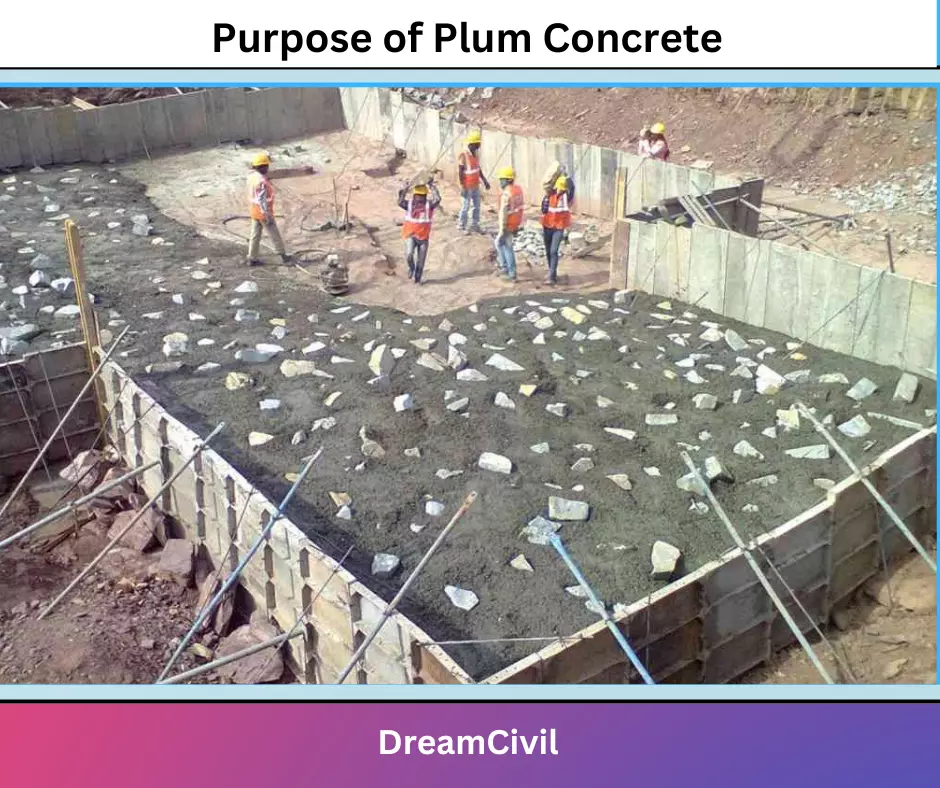

a. To achieve the required surface level, the plum concrete will be placed under the foundation or footing.

b. If the thickness of PCC needed is excessive and very large then to reduce the cost of PCC, plum concrete will be used.

c. Mainly used in mass construction such as bridges, gravity dams, and Side slopes of the embankment.

d. For instance, suppose in the offered site, there is a small area where the ground level is too sloped, and you can’t fill the space with soil. In that scenario, plums concrete would be employed as filler material.

2. Plum (Aggregate) Properties

The plum that is employed to make plum concrete requires to comply with the ASTM standard. Its preferred properties are as follows:

a. The size of natural stone or boulders, i.e., plum, is roughly 150 mm, 200 mm, 300 mm, or larger. The size is chosen depending on the project, availability of materials, and engineering decisions.

b. Angular-shaped stones are good for making plum concrete. It should be clean and free from oil, dirt, or other harmful materials that can compromise valid adhesion or bonding with concrete.

c. It should be of good grade, sound, durable, and free from segregation, seams, cracks, and other structural faults or imperfections.

d. It should be free from worn or weathered and rounded surfaces.

3. Difference Between Plain Cement Concrete and Plum Concrete

Plain cement concrete or PCC is a considerable form of Concrete. It is made by mixing primary ingredients such as cement, sand, and aggregates.

While in plum concrete, in place of aggregates, medium and large stones are employed as filler material rather than coarse aggregates.

So the distinct difference between PCC and plum Concrete is the boulders insertion in the concrete mix.

It works as a filler material, decreasing the number of coarse aggregates, which are expensive. Thus, it decreases the price of PCC.

4. Procedure of Plum Concreting

The procedure of Plum Concreting is as follows:

a. Levelling & Cleaning the surface

The suggested area should be cleaned and leveled. If low-hearing soft soil is present, it should be released from the site.

b. Waning the Surface

The surface area should be watered by spraying water to prepare the bonding strong between plum concrete and the ground surface. Occasionally termite resistance will also be kept to anti-termite treatment.

c. Material Inspection

Boulder must be strong, not flaky. It should be cleaned by washing it properly.

d. Boulder’s placement

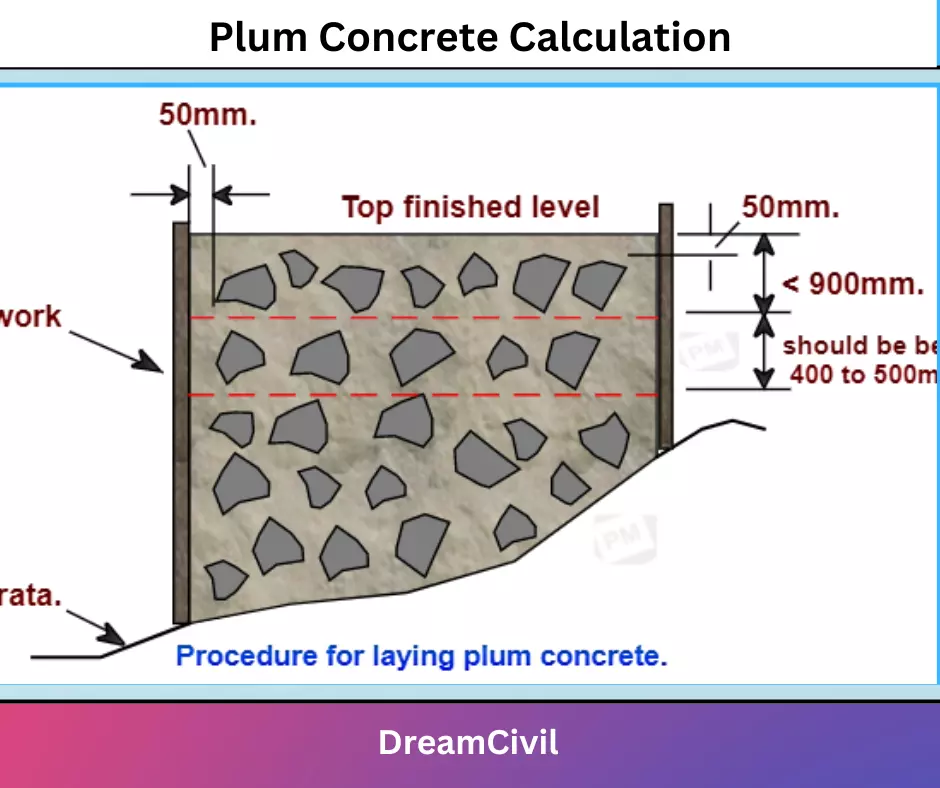

The boulders are positioned in layers with adequate gaps. The gaps must be less than 150 mm.

e. Concrete placement

Now the concrete will flow over the boulders, which gradually spread between the gaps.

f. Repeat

Once the concrete is distributed uniformly, again boulders will be kept and then concrete, the process will resume until the surface the needed level.

g. Curing

Curing should be accomplished for a minimum, of days. Change that the concrete will be moisturized by employing jute bags.

5. Plum Concrete Calculation

Plum concrete is primarily used for surface leveling. It ratio should be 40% boulders and 60% M10 or M20 concrete of its total volume.

For instance, Suppose an area of 10 square meters and the thickness required for concrete is about 1000 mm, then. Total Quantity of Plum Concrete = Area x Thickness = 10 x 1 = 10 m3.

a. Method 1

Total Cement Concrete Quantity = 60% of total Volume =10 x 60%= 6 m3 Total Plums (boulders) Quantity = 40% of total Volume = 10 x 4096 = 4 cum. The above calculation will provide you with a plum concrete of 10m3 where concrete will utilize 6 cum and rubble stone 4 cum.

It is very challenging to evaluate the number of rubble stones precisely as there is no fixed size and shape of rubble stones. Generally, we also assume the voids 20 to 4096 while computing the quantity.

b. Method 2

This method gives you precise calculations by evaluating the weight density of concrete at 2400 kg/m3 and the weight density of rubble stone 96 at 2850 kg/m3.

Plum concrete quantity = 10 cum cement Concrete quantity = 6 cum x 2400 kg=14400 kg

Rubble Stone Quantity = 4 m3 x 2850 kg =11400 kg

All the above-estimated quantities need to be calculated employing a weighing machine and employed thereafter.

6. Uses of Plum Concrete

The uses of plum concrete are as follows:

a. Mostly it is appropriate to level the ground under the foundation, where the surface is irregular. Further, it is also suitable to smooth the ground with a steep slope.

b. It is employed to make massive structures like gravity darns and bridges, but the plum size is determined to be 150 mm.

c. It is suitable for the construction of a surface bed of water channels.

d. It is basically employed for the construction of the borders of roads and railways bridges.

e. It is suitable for the construction of machine foundations where mass concrete is required.

| Read Also: Wing Walls |