Table of Contents

PCC Full Form in Civil Engineering is Plain Cement Concrete. The cement concrete in which no reinforcement is provided is called Plain Cement Concrete (PCC).

✔ It is simply a mixture of cement, sand, and aggregate containing a suitable proportion of water.

✔ It is sometimes called mass cement concrete or cement concrete.

✔ It is considerably stronger in compression but weak in tension and shear.

1. Ingredients of PCC

a. Cement

~ Portland Pozzolana Cement(PPC) is commonly used cement in Plain Cement Concrete.

~ It should have a suitable degree of fineness.

b. Sand ( Fine aggregate )

~ The sand used should be hard, sharp, and angular.

~ The size of sand should be smaller than 5 mm (i.e. sand passing through a 5 mm square sieve is used).

~ Sand should be free from dust, organic particles, etc.

~ Sea sand is not suitable for concrete because of its very weak bonding capacity.

c. Coarse aggregate

~ It is simply called aggregate.

~ Aggregates used should be free from dust, and foreign materials and also hard to resist enough stresses.

~ Generally, stone ballasts passed through the square sieve of 20 mm and retained in the square sieve of 5 mm are used as coarse aggregates.

~ Aggregates should be well graded so that the voids do not exceed 42% in any case.

d. Water

~ Water to be used should be free from oils, acids, alkalis, salts, and vegetable growths.

~ Water having a pH value of less than 6 is not suitable for use in plain cement concrete.

2. Uses of PCC

Some of the uses of plain cement concrete are:

a. It is commonly used in the construction of the column foundation, massive gravity dams, flooring, etc.

b. It is used in rigid pavement construction (reinforcement-less rigid pavement).

c. In small-scale canal construction; PCC is used.

d. It is also used in some stone masonry works.

3. Properties of PCC

Some of the properties of plain cement concrete are:

a. Strength

The PCC should have high compressive strength.

The tensile strength should be 8-12% of compressive strength and the shear strength should be 8-10% of compressive strength.

The compressive strength of the PCC depends upon the following:

i. Cement Content

ii. Water Cement Ratio

iii. Method of mixing, placing, compacting, and curing.

iv. Quality of materials used

v. Age of the concrete.

b. Durability

PCC should be able to resist climatical as well as chemical actions to be durable.

c. Workability

PCC should be highly workable. It should be easy to mix, manage, and transport. It should be free from bleeding and segregation.

Workability can be tested with a slump test.

d. Fire Resistance

PCC should be highly resistant to the fire to prevent problems like firing, spalling of concrete, etc.

4. Preparation of Plain Cement Concrete (PCC)

Plain Cement Concrete preparation includes the following processes:

a. Selection and preparation of ingredients.

b. Mixing of ingredients

c. Transportation and placing

d. Compaction of Concrete

e. Finishing of surface

f. Curing of concrete

a. Selection and preparation of ingredients

Various ingredients such as cement, sand, aggregate, and water should be carefully selected according to the purpose and strength of the concrete desired.

b. Mixing of ingredients:

Ingredients of PCC are mixed properly with their relative proportion.

Mixing may be of two types:

i. Hand mixing

ii. Machine mixing

i. Hand mixing:

It is the manual process of mixing ingredients by laborers.

This method of mixing is less suitable because more cement is required than in machine mixing.

Method of Hand Mixing

1. Hand mixing of concrete is performed on a rigid, clean, and non-porous base prepared of masonry or flat iron sheet plates.

2. The measured quantity of sand and aggregate is laid over the platform and then the cement is added as required.

3. Before adding the water, the mixture ( cement+sand+aggregate) is mixed properly with the use of shovels.

4. After dry mixing; water is added as required and further mixing work is done.

ii. Machine mixing

Machine mixing is the process of mixing the ingredients of concrete by the use of a machine and such concrete is called the machine-mixed concrete.

A machine used for the mixing of the concrete is called a mixer.

A machine used for the mixing can be operated manually or electrically.

Machine-mixed concrete is suitable if a large quantity of concrete is required.

Method of Machine Mixing

a. Coarse aggregate, sand, and cement of the required quantity are added to the drum of the mixer.

b. Mix the elements in a dry state for 1.5 to 3 minutes.

c. After uniform mixing of the dry materials; add the water slightly. Don’t add more water at once. Add water slowly in phases.

e. After adding water, you must blend the concrete in the drum for 2 to 3 minutes.

f. If there is any segregation seen right after unloading from the mixer, remix the concrete.

c. Transportation and Placing

The prepared concrete is transported manually in an iron pan or mechanically through a wheelbarrow or by buckets or with the help of the pump.

The media used in transportation depends upon the types and nature of the work.

The placing of concrete means the process of depositing to concrete in its required place and position as fast as possible.

d. Compaction of Concrete

To remove air bubbles or air voids and to make concrete more dense and compacted; the freshly placed concrete should be compacted with rollers, rods, and vibrators. This process is called the compaction of concrete.

Compaction at a place should be done for a minimum of 5 seconds and should not exceed 15 seconds in any condition.

There may be needed for a needle vibrator and a surface vibrator for compaction.

A needle vibrator is generally used to compact the concrete in small, narrow, and deep areas like a beam, column, etc, and is sometimes used in a flat area but the surface vibrator is used in compaction of a flat area like a road construction.

e. Finishing of surface

Finishing means the removal of irregularities and voids present on the surface.

After concreting, the rough concrete surface is leveled and smoothed during the finishing process.

f. Curing of concrete

Wet curing by jute bags and clothes is done after 2 /3 hours of concrete laying.

After 24 hours, ponding or spraying curing is done for a minimum of 14 days.

In rainy areas, concrete should be covered to protect from water for 24 hours.

5. Dos & Don’ts of PCC Work

Dos

a. When PCC work is to be carried out underground; loose materials from the side of the pits or trenches should be removed.

b. De-watering should be done before PCC work when the water table is high.

c. Water should be added to the concrete according to the water-cement ratio.

d. Shuttering used in the PCC work should have the same size and thickness.

Don’ts

a. Mixing concrete on bare land should not be done.

b. PCC work without formwork should not be allowed.

c. Pouring of concrete from more than 1.5 m in height should not be done.

Read Also: Curing of Concrete

6. PCC Full Form in Civil Engineering

The full form of PCC in Civil Engineering is Plain Cement Concrete.

This was for the PCC Full Form in Civil Engineering.

7. FAQ

1. Curing of PCC should be done for?

⇒ Minimum 14 days

⇒ Best to do for 28 days if possible.

2. PCC stands for?

⇒ PCC Full Form in Civil Engineering is Plain Cement Concrete.

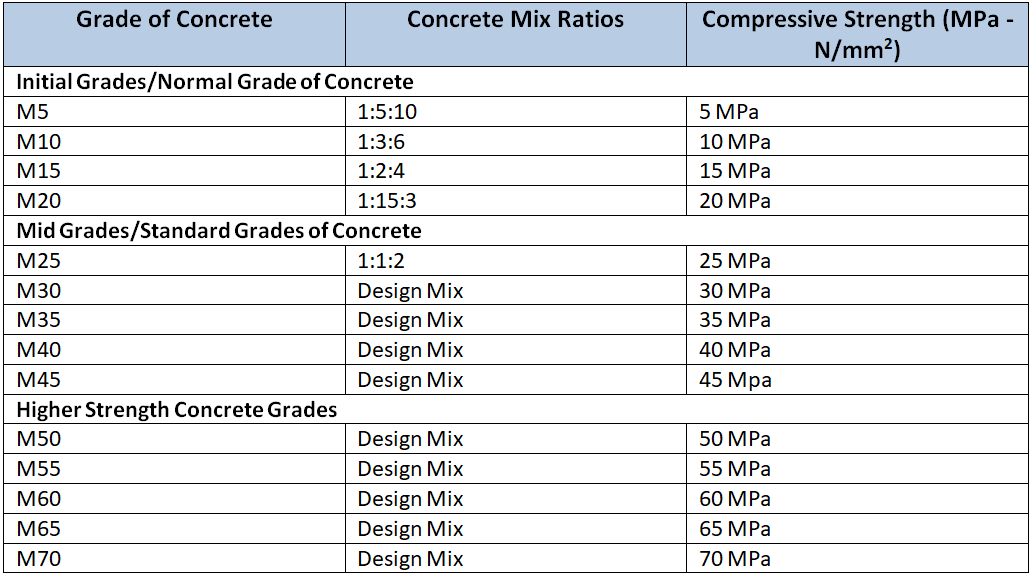

3. Grade of PCC based on IS?

⇒ The grade of PCC based on IS is listed below:

4. Application of PCC?

⇒ The application of PCC are as follows:

✔ Gardening & Landscaping

✔ Rigid pavement construction

✔ Base preparation for foundation, dams, etc

✔ Flooring

8. References1. Content Filter & Authenticity Checking Team, Dream Civil International (Our team checks every content & detail to maintain quality. ) |

Read Also: Types of Concrete Admixtures