Table of Contents

Micropiles are generally high-strength, durable, small-diameter about 6-12” (150-300 mm) steel casing pile or rib or bar and stuffed with a high-strength cement grout used to borehole.

Micro piles are also known as Mini Piles / Pin-Piles / Root Piles.

The bearing stratum is logged throughout installation drilling to make sure that bearing capability is satisfactory.

Since small piles are less in diameter they will be progressed through the bottom at a better speed and may damage through materials with more considerable ease than a caisson casing or a driven pile.

The micropiles will pierce any obstructions which will typically cause premature refusal whereas placing in mistreatment typical spile strategy.

Grouting action is performed by tremie grouting, pressure grouting during the period of casing retraction, and tremie grouting with post-grouting.

Post-grouting among the bond length will improve resistance forces with close soils, so acquiring more considerable capability.

Micropile abilities in way over four hundred kips (1,780 KN). Micropiles to depths exceeding two hundred feet (60 m).

1. Procedures to Install Piles

The procedures to install piles are as follows:

a. Drilled into bedrock, micro-piles are related to the rock socket wall for fetching a load.

b. The casings of the mini piles are run as piles are drilled into bedrock.

c. The drill rod is removed and the steel casing stays there.

d. On getting the saturation level the drilling bit is removed with casing kept within the borehole.

e. A reinforcement load rod is dropped into the casing.

e. Given reinforcement with centralizer within the borehole, along with tremie grout & cement water blend.

f. Cementitious grout along with pressure is provided into the minipile casing and rock socket.

g. After Tremie grouting, conduct a pressure grouting through preinstalled grouting tubes.

g. The casings for the mini piles are heaved up to a high bedrock, which allows bonding to the bar. Extra steel is trimmed from the superior of mini piles.

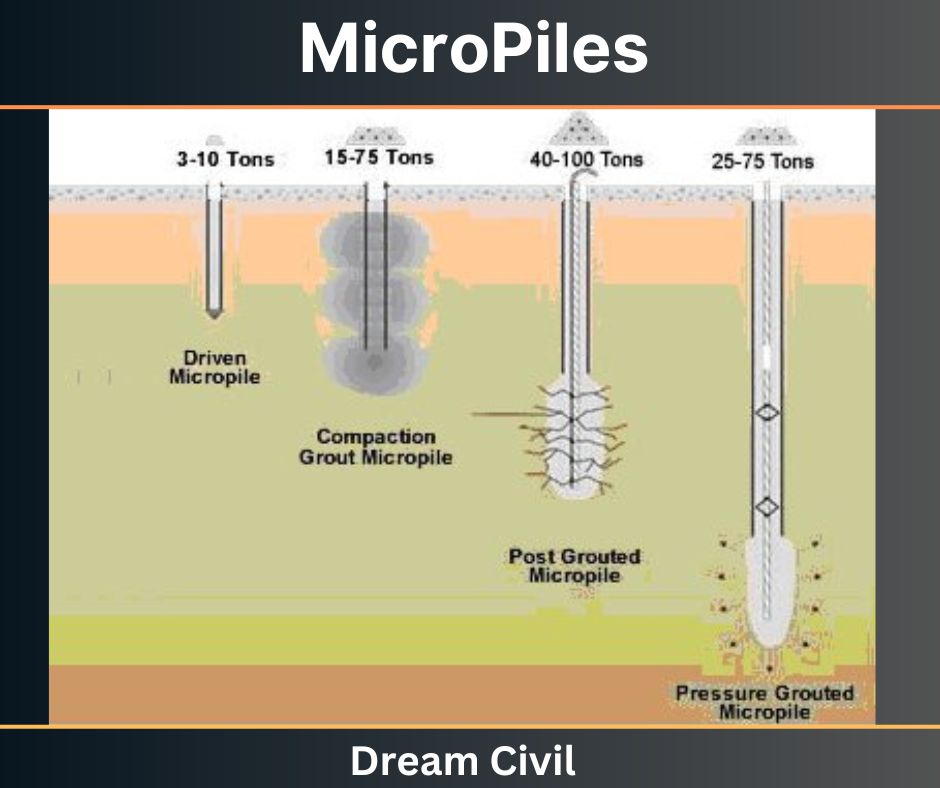

2. Types of Micropile

Micropiles are majorly classified into 2 types:

a. Displacement Piles

Displacement piles are moved or vibrated into the base, thereby replacing the adjacent soil sideways at the time of the inauguration.

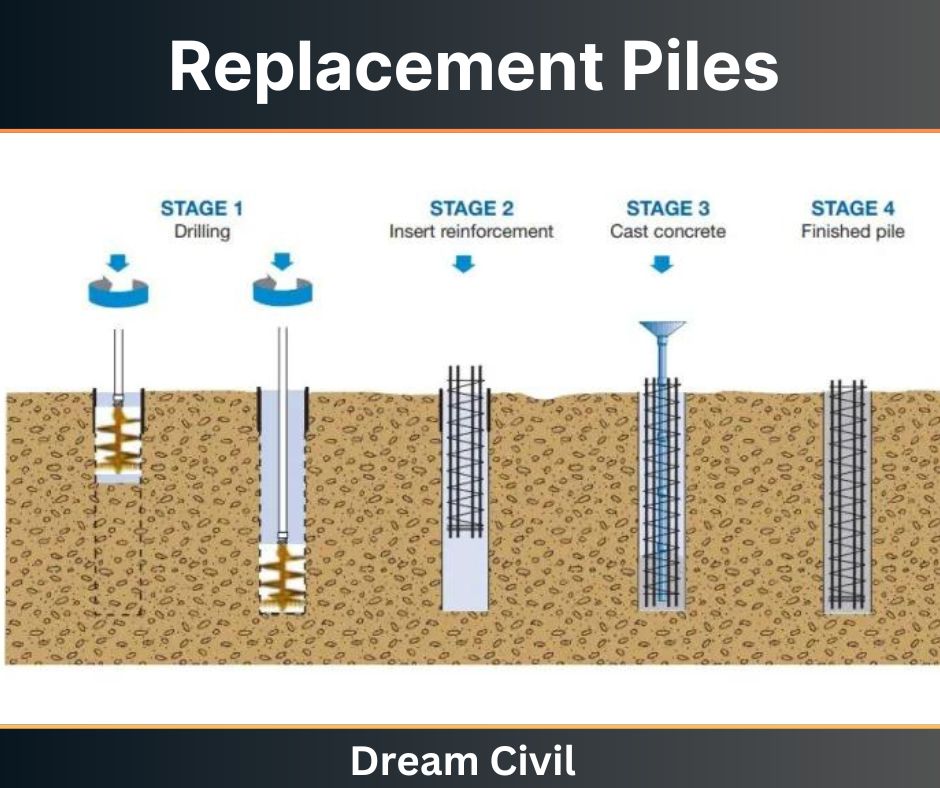

b. Replacement Piles

Replacement piles are made within a previously drilled borehole, thus repairing the unearthed ground.

Micropiles as Per Based on Design:

Relying on the design use of mini piles is categorized into 2 cases:-

Case 1:

Micro-pile parts, which are loaded instantly & where the pile reinforcement resists the bulk of the given load.

Case 2:

Micro-pile parts circumscribe and internally reinforce the soil to make a reinforced soil composite that resists the applied load.

3. Uses of Micropile

The uses of micropile are as follows:

a. Used to give structural support

b. Used to underpin your foundation

c. Used to transfer hundreds

d. Used to enhance mass stability

4. Advantages of Micropile

The advantages of micropile are as follows:

a. They’re small and comparatively very lightweight.

b. They’re cheap than the other types of piles.

c. Simultaneous drilling and grouting permit low overhead, limited access facility.

d. Micropiles are generally chosen to “H” piles attributable to overhead physical restrictions.

e. Enhances the bottom (densification).

f. Delivers more increased skin friction.

g. Total single corrosion safety calculatedly.

h. Piling rigs may be low-emission or maybe electrically driven.

i. The limited vibration and noise cause very little trouble.

j. They can be set on the point of existing walls with limited headroom and engorged website requirements.

k. Micro-piles are good at penetrating any surface.

l. They have a high load ability and the power to withstand compressive, tensile, and lateral masses.

5. Disadvantages of Micropiles

The disadvantages of micro piles are as follows:

a. If there aren’t any obstacles they’re longer overwhelming than a driven pile

b. Valuable

c. Water infill is often a problem

6. Micropile Cost

The cost of micropile with all details is as follows:

| Detail | Amount |

| Micro Piles | $1,026,000 |

| F/R/P Pile Caps | $39,039.56 |

| F/R/P Grade Beams and Piers | $75,354.92 |

| F/R/P Foundation Walls | $18,583.76 |

| Concrete ‐ 3000 psi | $81,456 |

| Total Value | $1,240,434 |

7. References1. Content Filter & Authenticity Checking Team, Dream Civil International (Our team checks every content & detail to maintain quality.) |

Read Also: Types of Resilient Flooring