Table of Contents

Concrete is the homogeneous mixture of cement or lime, sand, aggregate, and water in a fixed proportion. Its quality plays a vital role in the strength and durability of the structure. Hence, the quality of concrete is expressed in terms of grades of concrete.

Higher the grade; higher will be the quality of concrete and vice versa.

Different nations have their grades of concrete. We will discuss some of them.

1. Grades of Concrete Based on Indian Standard ( IS )

The grade of concrete is the minimum strength that the quality-controlled concrete posses after 28 days of construction.

There are different grades of concrete like M15, M20, M25, M60, etc.

Normal grade concretes like M10, M15 & M20 are used for small-scale constructions.

For large scale constructions; standard-grade & high-grade concrete like M25,M40, M45, M50, etc are used.

There is a requirement for design mix in high-grade concretes.

{Note:

In M20 grade concrete

“M” stands for Mix ratio of cement:sand: aggregate & “20 “Stands for Compressive Strength.

}

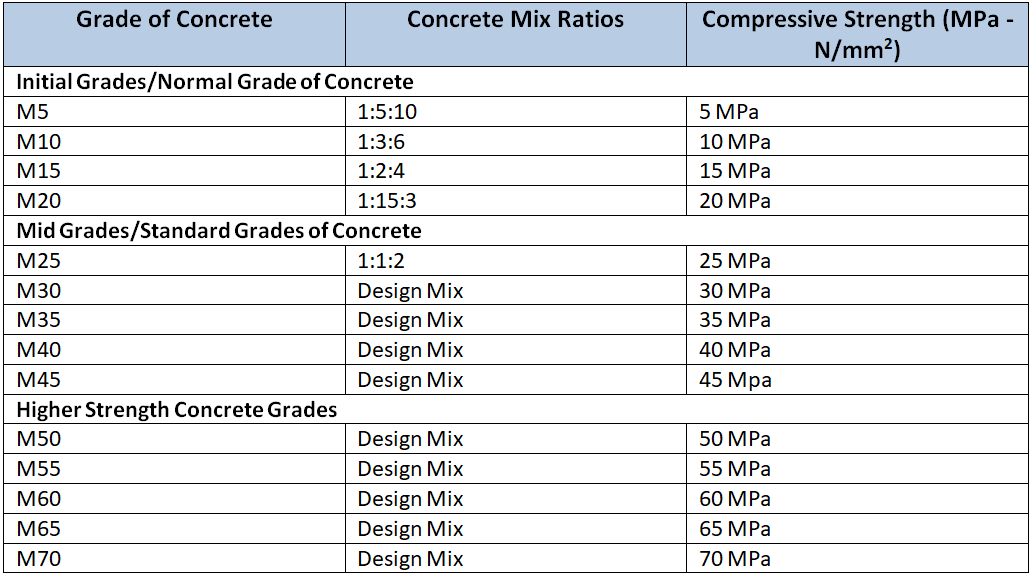

Table – Grades of Concrete Based on IS

{Note:

~ Concrete less than M20 grade should not be used in the RCC work as per code IS 456:2000.

~ PQC stands for Pavement Quality Concrete.

}

i. Normal grades of concrete

a. M5 Grade

- The mixing ratio is 1:5:10 ( 1 part of cement, 5 parts sand, and 10 parts aggregate).

- Compressive strength is 5 MPa.

- They are used in foundation beds to prevent direct contact between soil and foundation concrete.

b. M7.5 Grade

- The mixing Ratio is 1:4:8 ( 1 cement part: 4 sand part: 8 aggregate part).

- Its compressive strength is 7.5 MPa.

- Used in foundation bed to prevent direct contact between soil and foundation concrete. (same as M5)

c. M10 Grade

- Mixing Ratio is 1:3:6 ( 1cement part: 3sand part: 6 aggregate part).

- Its compressive strength is 10MPa.

- They are used in the base of footing, levelling works, road construction, etc.

d. M15 Grade

- Mixing Ratio is 1:2:4 ( 1cement part: 2 sand part: 4aggregate part).

- Its compressive strength is 15 MPa.

- They are used as Plain cement concrete ( PCC).

- They are used in the base of footing, levelling works, road construction, etc.

e. M20 Grade

- Mixing Ratio is 1:1.5:3 ( 1cement part: 1.5 sand part: 3aggregate part).

- Its compressive strength is 20 MPa.

- Used as Reinforced Cement Concrete(RCC).

- Used for construction of slabs,beams,columns,etc.

ii. Standard grades of concrete

a. M25 Grade

- Mixing Ratio is 1:1:2 ( 1cement part: 1 sand part:2aggregate part).

- Its compressive strength is 25 MPa.

- Used as Reinforced Cement Concrete(RCC).

- Used for construction of slabs,beams,columns,etc.

b. M30 Grade

- M-30 Mix Designs as per IS-10262-2009

- Used as Reinforced Cement Concrete(RCC).

- Used for construction of slabs,beams,columns,etc.

c. M35 Grade

- M-35 Mix Designs as per IS-10262-2009

- Used as Reinforced Cement Concrete(RCC).

- Used for construction of slabs,beams,columns,etc.

d. M40 Grade

- M-40 Mix Designs as per IS-10262-2009

- Used as Prestressed Concrete.

- Used for construction of slabs,beams,columns,etc.

e. M45 Grade

- M-45 Mix Designs as per IS-10262-2009

- Used as Reinforced Cement Concrete (RCC)

Used in the followings:

i. Runways

ii. Concrete Roads (PQC)

iii. Pressurized Concrete Girders

iv. Pressurized beams

v. RCC Columns

f. M50 Grade

- M-50 Mix Designs as per IS-10262-2009

- Used as Reinforced Cement Concrete (RCC)

Used in the followings:

i. Runways

ii. Concrete Roads (PQC)

iii. Pressurized Concrete Girders

iv. Pressurized beams

v. RCC Columns

g. M55 Grade

- M-55 Mix Designs as per IS-10262-2009

- Used in the Pressurized Concrete Girders.

- Used in the Pressurized Concrete Piers.

iii. High-strength concrete grades

For M60 to M80 Grade of Concrete

These grades of concrete are used in the following sectors:

a. Construction of high-rise buildings, spillways of dams, long-span bridges, etc.

b. It can be used in work where the environment is quite aggressive.

iv. Tricks to remember grades of concrete

M5 has 1:5:10

M7.5 has 1:4:8

M10 has 1:3:6

M15 has 1:2:4

M20 has1:1.5:3

M25 has 1:1:2

From this list, we can note;

a. The ratio of cement is constantly 1 for M5 to M25.

b. The ratio of sand is in descending order from 5 to 1. (except M20 of 1.5)

c. The ratio of aggregate is equal to 2 times of ratio of sand of grades.

Examples:

For M5,

5 part sand: ( 5×2) part aggregate

For M7. 5,

4 part sand: ( 4×2) part aggregate

And so on.

2. Grades of Concrete Based on British Standard (BS)

As per BS 8500-2, the grades of concrete are represented as C10, C20, C40, etc.

{ Note:

In C10 grade concrete

‘C’ represents Concrete Strength Class, and 10 means 10 N/mm² Compressive Strength of Concrete @ 28 days when tested with the 15cm dia & 30cm height cylinder in a direct compression test. }

i. Standard strength concrete grades

a. C10 Concrete Grade

- It is also known as Gen1 concrete.

- It gains 10 N/mm² compressive strength in 28 days.

- It can be used in trench fills, general floor binding, agricultural formations, and drainage.

- It is not suitable for structural mass formations.

b. C15 Concrete Grade

- It is also known as Gen2 concrete.

- It gains 15 N/mm² compressive strength in 28 days.

- It can be used to construct short walls, residential flooring, temporary structures, etc.

- It is not suitable for large-scale projects.

c. C20 Concrete Grade

- It is also known as Gen3 concrete.

- It gains 20 N/mm² compressive strength in 28 days.

- It is used to construct lightweight foundations, internal floor slabs, driveways, garages, and sheds.

d. C25 Concrete Grade

- It is also known as ST2.

- It is used in residential and commercial building projects to construct foundations, reinforced bases, etc.

ii. High-performance concrete grades

e. C30 Concrete Grade

- It is also known as ST3 or PAV1.

- It gains 30 N/mm² compressive strength in 28 days.

- It is used in reinforced bases, pavement construction, etc.

f. C35 Concrete Grade

- It is also known as PAV2.

- It gains 35 N/mm² compressive strength in 28 days.

- It is used in large-scale projects and constructions.

g. C40 Concrete Grade

- It gains 40 N/mm² compressive strength in 28 days.

- It is used in the construction of large industrial support beams and foundations.

3. Grades of Concrete Based on European Standard

The concrete grades are C16/20, C20/25, C25/30, C30/45, etc., which means C represents the Concrete Strength Class, and the number behind C refers to the Compressive strength of Concrete in N/mm² when tested with Cylinder / Cube.

{ Note:

1MPA = N/mm2 }

| Concrete Grade | fck (MPa) | fck, cube (MPa) | Ecm (GPa) |

| C12/15 | 12 | 15 | 27 |

| C16/20 | 16 | 20 | 29 |

| C20/25 | 20 | 25 | 30 |

| C25/30 | 25 | 30 | 31 |

| C30/37 | 30 | 37 | 33 |

| C35/45 | 35 | 45 | 34 |

| C40/50 | 40 | 50 | 35 |

| C45/55 | 45 | 55 | 36 |

| C50/60 | 50 | 60 | 37 |

| C55/67 | 55 | 67 | 38 |

| C60/75 | 60 | 75 | 39 |

| C70/85 | 70 | 85 | 41 |

| C80/95 | 80 | 95 | 42 |

| C90/105 | 90 | 105 | 44 |

Ecm = Elastic modulus of concrete

4. Grades of Concrete Based on American Standard

| Concrete Mix | Cylinder Strength (psi) | Cylinder strength (MPa or N/mm²) |

| 2000 | 2000 | 13.8 |

| 3000 | 3000 | 20.7 |

| 4000 | 4000 | 27.6 |

| 5000 | 5000 | 34.5 |

| 6000 | 6000 | 41.3 |

| 8000 | 8000 | 55.2 |

| 10000 | 10000 | 68.9 |

5. Grades of Concrete Based on Canadian Standard

The concrete grades of strength 20 Mpa to 40 MPa are listed in the Canadian standards for general use.

The strength of concrete greater than 70 MPa is classified as high-strength concrete.

The highest strength of concrete, 220 MPa, has also been used in building applications.

6. Grades of Concrete Based on Australian Standard

Prefix N is used to symbolize concrete grades, and the value of the strength of concrete ranges from N20 to N100 by Australian Standard.

| Concrete Mix | Cylinder Strength (MPa) |

| N20 | 20 |

| N25 | 25 |

| N32 | 32 |

| N40 | 40 |

| N50 | 50 |

| N65 | 65 |

| N80 | 80 |

| N100 | 100 |

| Read More: Types of Concrete |