Table of Contents

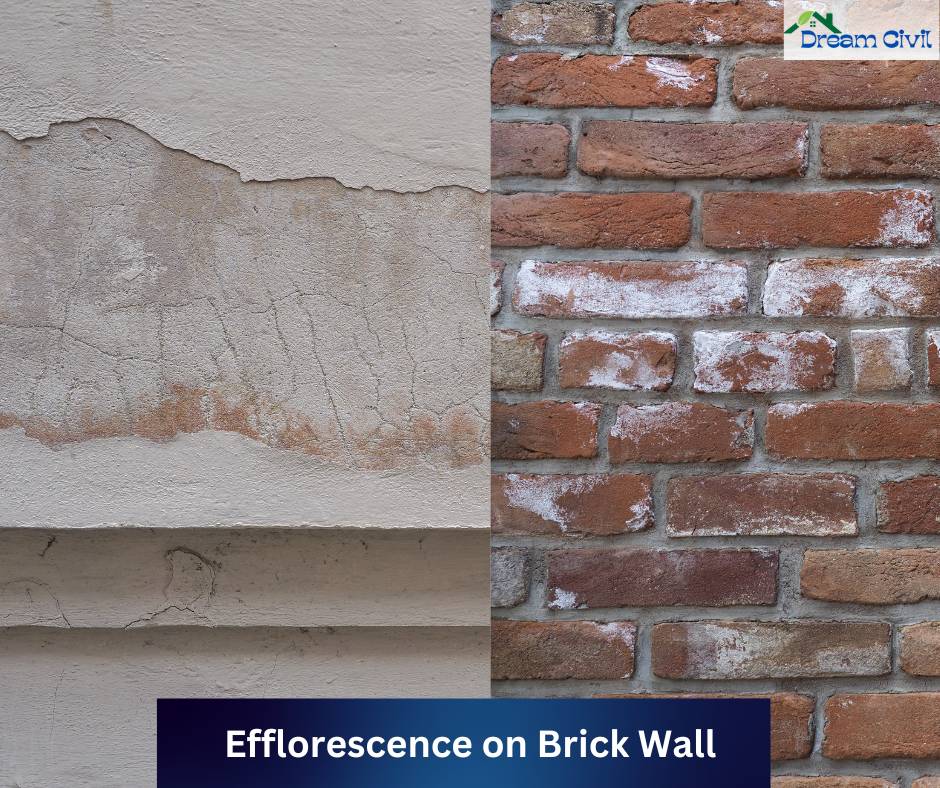

Efflorescence on brick wall means the appearance of white-colored powder material on the wall’s surface.

✔ The alkaline salt in the brick used in the wall absorbs moisture from the air, which leaves powder deposited on the wall’s surface on drying.

✔ It is also caused if pyrite is present in clay used for brick making or water used for pugging contains gypsum.

1. What are the Effects of Efflorescence on Brick Walls?

Some effects of efflorescence are as follows:

a. Unhygienic condition

b. Decaying of wood attached to the wall.

2. What are the Causes of Efflorescence on Brick Walls?

Some causes of efflorescence are:

1. One or many constituents of the wall may contain salt.

2. High water-cement ratio resulting in a more porous mortar.

3. Inadequate wall curing may leave unhydrated products on the surface.

4. Exposure to rain or other sources of water.

5. The slow water evaporation rate allows the salt to permeate to the surface.

3. What are the Preventive Measures of Efflorescence on Brick Walls?

Some preventive measures for efflorescence are:

1. Use ingredients containing as little soluble salt as possible.

2. Use waterproofing admixtures in a mortar to reduce the permeability of the brick wall.

3. Avoid premature drying.

5. Use cement, lime, and mortars that are no stronger than required for the application to minimize possible soluble salt levels.

6. For masonry, ensure the flashing and damp proof courses are detailed correctly. Cover the top course at the end of each day’s work.

3. How to Eradicate Efflorescence on Brick Walls?

To eradicate the efflorescence problem, the moisture ingress source should be determined first. The cause of ingress may be defective DPC, absence of DPC, or other reasons.

Steps in the eradication of efflorescence are as follows:

✔ The first action is to stop the source of ingress of moisture.

✔ The second step should be to remove the Plaster from the inside and outside the wall and leave it dry.

✔ Then remove the defective brick or fill voids with mortar, cement slurry, or cement concrete.

✔ Check the mortar joint carefully and remove loose mortar where necessary.

✔ Wash the white patches from the surface with the acidic water and then rewash them with clean water.

✔ Plaster inner and outer surfaces with cement mortar, adding waterproofing admixture.

✔ If the causes are due to the absence of the DPC course or the failure of DPC, a new course of DPC should have to be introduced or replace the defective DPC with the new one.

DPC can be done by the following;

1. Cleaning the Surface

The surface can be cleaned in the following ways before the DPC application.

a. Brushing

✓ Soluble salts deposited can be removed with a stiff bristle broom. Note that all brushed materials should be removed by a vacuum cleaner or other means.

✓ If the result is not satisfying, scrub with a scrubber and lightly rinse the surface. Adding water may result in further deposits; repeated dry brushing as the deposit appears is probably the best.

✓ Water washing cannot remove insoluble salt deposits, although using a high-pressure water jet is effective.

b. Using a dilute acid solution

✓ The application of a dil. An acid solution is also very effective in most cases, and in some cases, extreme care is required while handling acids. When diluting HCL acid, always add the acid to the water, never the reverse.

✓ Ensure good ventilation and avoid contact between the acid and the reinforcement. The concrete surface should be cleaned with only diluted acid.

✓ The recommended proportions are 1 part of HCL and 20 parts of water. The surface should always be saturated before the application of dilute acid. When applying the acid solution, ensure that the surface is moist without any free water.

✓ Then, the applied solution should react on the concrete surface for 10-15 minutes.

✓ The surface should be thoroughly rinsed and scrubbed with clean water. Repeat rinsing at least twice or until all traces of the acid solution have been removed. The process may be repeated if required to bring the necessary surface finishing.

2. Application of DPC

✓ After cleaning the surface, a suitable DPC is applied to the desired surface.

| Read More: Plastering Work |

| Read More: Grades of Concrete |

| Verified Article By Er. Madhu Krishna Poudel |