Table of Contents

A composite material may be defined as a mixture of two materials with dissimilar physical and chemical properties.

When combined they make a new material that is specific to a particular work, for instance, to become more powerful, lighter, or withstand electricity and also enhance strength and stiffness.

Composites, also known as Fiber-Reinforced Polymer (FRP) composites

1. Composite Materials

The materials preserve their identity within the composite, i.e. they do not dissolve or fully integrate into one another, though they work as a unit.

Composites material are likely the most broadly utilized materials due to their adaptability to various conditions.

It is easy to combine with various materials and the efficiency of desirable features to perform certain work.

The composite materials contain high strength and hardness with reduced density than bulk materials.

2. Types of Composite Materials

Some commonly used composite materials contain:

a. Ceramic matrix composite

Ceramic is applied out in a ceramic matrix. These are more useful than normal ceramics as they can withstand thermal shock and fracture. Ceramic matrix composites (CMCs) are commonly utilized in the aerospace field (gas turbines, structural re-entry thermal protection) and the energy field (heat exchangers, fusion reactor walls).

b. Metal matrix composite

A metal scattered entire a matrix. The metal matrix composite is more appropriate for a broad range of use in transportation, cutting tools, consumer electronics, defense, space, aerospace, marine, etc.

c. Reinforced concrete

Concrete is made strong by a material having high tensile strength such as steel reinforcing bars. It has high tensile strength and greatly improved ductility compared to normal concrete.

d. Glass fiber reinforced concrete

Concrete flows into a glass fiber structure having a high zirconia content. Glass fiber concretes are mostly utilized in outer building façade panels and as architectural precast concrete.

e. Translucent concrete

Concrete that covers optic fibers. Translucent is appropriate for floorings and pavements and is also utilized in staircases and desks.

f. Engineered wood

Manufactured wood integrated with other inexpensive materials. One of the best examples would be particle board.

A specialty material like veneer can also be encountered in this composite.

g. Plywood

Engineered wood by gluing multiple thin layers of wood jointly at various angles. The plywood can be used for the following purposes:

a. Light partition or external walls.

b. Formwork.

c. Furniture.

h. Engineered bamboo

Strips of bamboo fiber are glued jointly to prepare a board. This is a proper composite due to the fact it has more increased compressive, tensile, and flexural strength than that of wood.

i. Parquetry

A square of multiple wood pieces is kept together usually out of hardwood. It is sold as a decorative item.

j. Wood-plastic composite

Either wood fiber or flour is cast in plastic. It is an environmentally friendly approach to using waste wood and recycled plastic material.

k. Cement-bonded wood fiber

Mineralized wood slices cast in cement. This composite holds insulating and acoustic features. It is utilized to make a broad variety of products mainly for the construction industry (products like insulating concrete forms, siding materials, and noise barriers).

l. Fiberglass

Glass fiber is integrated with plastic which is fairly cheap and flexible Carbon.

m. Fibre-reinforced polymer

Carbon fiber is set in plastic which contains a high strength-to-weight ratio. It is utilized in aircraft, helicopters, and spacecraft through to boats, ships, and offshore platforms and to automobiles, sports goods, chemical processing equipment, and civil infrastructure.

n. Sandwich panel

A sort of composites is kept on top of each other. It is majorly utilized as an external cladding for single and multi-story buildings, where they are needed to deliver weather resistance, and resistance to wind-loading, access loads, self-weight, and so on.

o. Composite honeycomb

A selection of composites in many hexagons forms a honeycomb shape. They are utilized mostly in multiple industries, from aerospace industries, automotive, and furniture to packaging and logistics.

p. Papier-mache

Paperbound has an adhesive. These are found in crafts. It is generally utilized for large, temporary sculptures such as Carnival floats. A primary structure of the wood, metal, and metal wire mesh, such as poultry netting, is protected in paper-mâché. Once dried, details are kept. The papier-mâché is then sanded and painted.

q. Plastic-coated paper

Paper is covered with plastic to enhance durability. An example of where this is utilized is in playing cards.

r. Syntactic foams

Light materials are made by filling metals, ceramics, or plastics with micro balloons. These balloons are prepared to utilize either glass, carbon, or plastic.

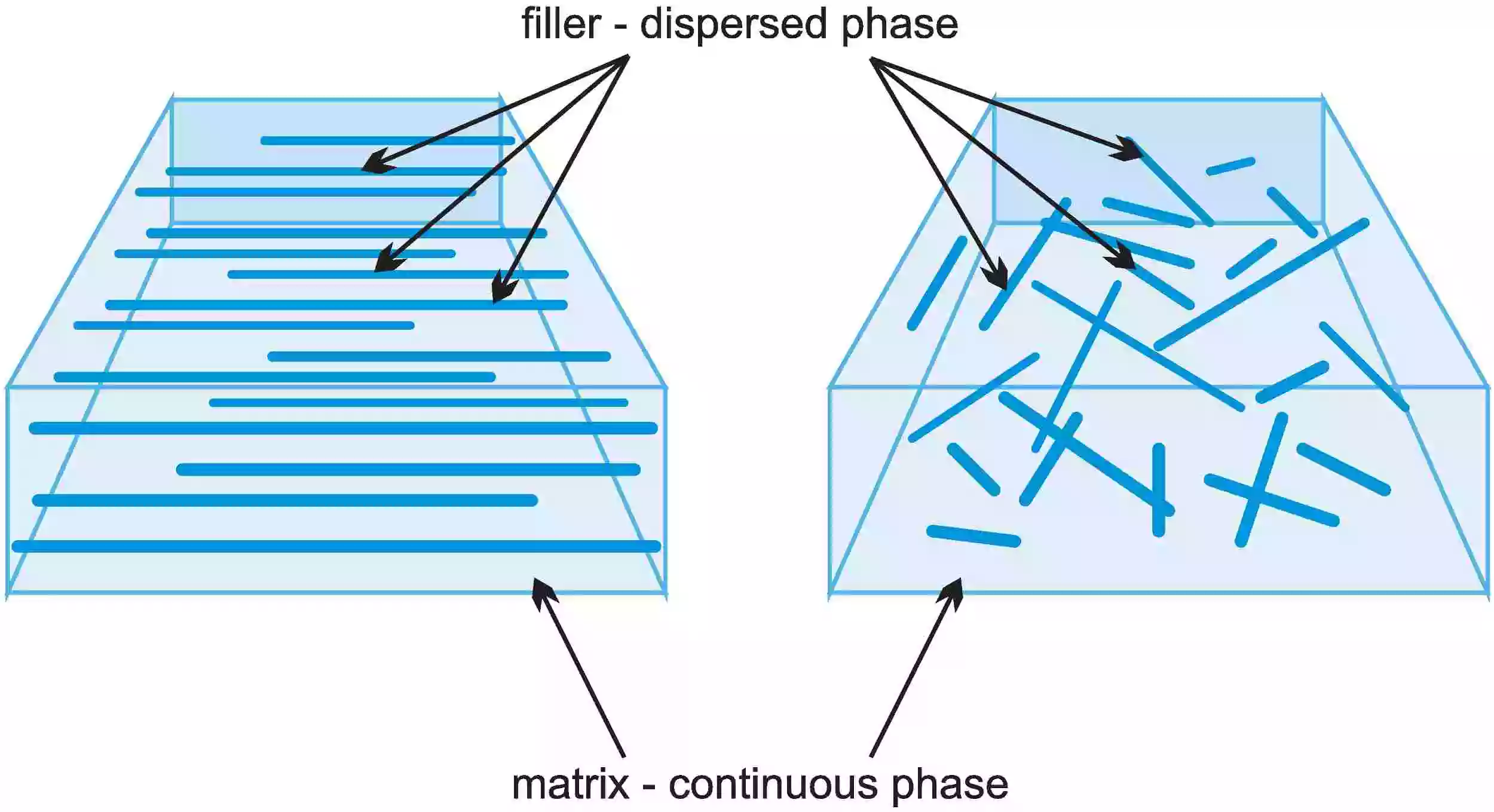

3. Composites Made Of

Composites are prepared from a polymer matrix that is supported with an engineered, man-made, or natural fiber (like glass, carbon, or aramid) or other supporting material.

The matrix covers the fibers from environmental and external damage and shares the load between the fibers. The fibers, in turn, deliver strength and stiffness to support the matrix and assist it resists cracks and fractures.

In numerous of the industry’s products, polyester resin is the matrix, and glass fiber is the reinforcement. But various hybrids of resins and reinforcements are utilized in composites and each material donates to the properties of the completed product:

Fiber, powerful but brittle, delivers strength and stiffness, while more flexible resin gives shape and covers the fiber.

FRP composites may also include fillers, additives, core materials, or surface finishes developed to enhance the manufacturing process, appearance, and performance of the resulting product.

4. Uses of Composite Materials

The uses of composite materials are as follows:

1. In automobile industries (e.g. Steel &Aluminum bodies)

2. Marine applications Ike shafts, lulls. spars (for racing boats)

3. Aeronautical application components of rockets. aircraft (business and military).missiles

4. Communication antennae, electronic circuit boards (e.g. PCB. breadboard).

5. Strengthening of damaged structures.

| Read Also: RCC Framed Structure |