Table of Contents

1. Introduction

Road pavement is an essential component of the transportation system that provides access and facilitates the linkages from one corner of the world to another. One of the chief components of the road pavement is the camber.

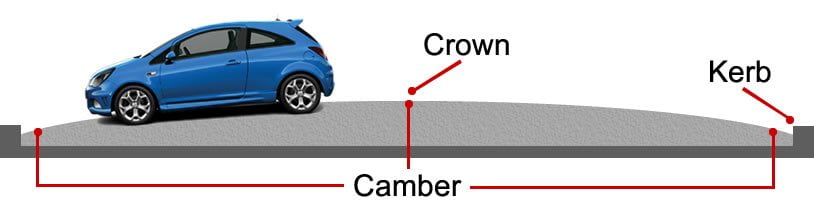

Camber in road pavement is the traverse slope provided to facilitate the efficient drainage of water thereby ensuring quality performance of the road pavement.

In other words, camber is the transverse slope that is provided on the pavements so as to raise the middle portion of the pavement in a traverse direction to drain off the water.

Pavement Camber is also commonly referred to as the cross slope of the highway pavement or cant.

The primary objective of providing camber in pavements is to drain off the rainwater from the surface of the road pavement.

Mostly, camber is expressed in proportions as n% or in ratio as 1: n or 1 in n i.e. 1 vertical to n horizontal. For example, it can be expressed as 2% or 1: 50 or 1 in 50.

The design values of the camber are computed depending upon two main factors. These factors include the type of highway pavement and the amount of rainfall or runoff that is accumulated on the surface of the pavement.

2. Objectives of Camber in Road Pavement

The main objectives of providing camber in the highway pavements can be listed as follows:

a. To drain off the rainwater or runoff from the surface of the highway pavement.

b. To prevent the ingress of water into the bituminous layers of the pavement.

c. To prevent the passage of water to the lower subgrade layer of the pavement.

d. To ensure quick drying of the surface of highway pavement particularly after rainfall so as to prevent the reduction in skid resistance.

e. To ensure the quality performance of the highway pavement and regulation of the vehicles on proper lanes.

3. Types of Camber in Road Pavement

In general, the camber can be classified into four major categories namely,

a. Straight Camber ( Sloped Camber)

b. Composite Camber

c. Two Straight Line Camber

d. Parabolic Camber ( Barrel Camber)

These types have been further explained in brief as follows.

1. Straight Line Camber/ Sloped Camber

Straight Line Camber consists of two slopes originating from the edges and joining at the center of the carriageway.

It is the simplest type of camber. It can be constructed quite easily and the maintenance of such a camber is also simple.

Fig: Straight Line Camber

2. Two Straight Line Camber

This camber consists of two straight lines that are steeper near the edges and relatively flatter near the crown portion of the highway pavement.

Fig: Two Straight Line Camber

3. Parabolic Camber (Barrel Camber)

Parabolic Camber consists of a continuous curve. The continuous curve may be either parabolic or elliptical.

This type of camber provides a steeper surface towards the edges and a flatter surface towards the middle portion.

Due to the steep edges, the drainage of the water is highly efficient. Thus, parabolic camber is highly desirable for highway pavements in urban areas with fast-moving vehicles.

However, this type of camber is relatively difficult to construct.

Fig: Parabolic Camber

4. Composite Camber

It consists of a parabolic or circular crown at the center of the camber and two straight slopes originating from the edges.

Fig: Composite Camber

4. Method of Camber Construction

After the suitable design value of the camber has been computed, it is duly provided on the highway pavement.

First of all, templates or the camber boards are prepared with the required camber.

Then, the material to be used for the subgrade is duly spread and paced until the desired shape of the camber is achieved.

The rolling of the spread material is carried out. It must be ensured that the rolling is done from the edge towards the center.

After rolling is completed, the top surface is checked by means of the templates and camber boards.

Finally, the excess of the material is removed in case of excess, and additional material is spread in case of deficiency of material.

5. IRC Recommended Values for Camber

As per IRC, the recommended values of camber for different types of highway pavements can be listed as follows:

a. For bituminous surface pavements or concrete surface pavements, the recommended camber value is 1 in 50 ( heavy) and 1 in 60 (light).

b. For thin bituminous surface pavements, the recommended camber value is 1 in 40 ( heavy) and 1 in 50 (light).

c. For water-bound macadam and gravel surface pavements, the recommended camber value is 1 in 33 ( heavy) and 1 in 40 (light).

d. For earthen surface roads, the recommended camber value is 1 in 25 (heavy) and 1in 33 (light).

6. Advantages of Camber in Road Pavement

Some of the advantages of providing camber in the road pavements can be listed as follows:

a. As camber facilitates the drainage of water from the surface of the pavement, it prevents the weakening of the surface.

b. Camber also prevents the percolation of water to the underlying layers thus deterioration of the foundation by water percolation is eliminated.

c. Camber prevents the formation of water pools on the surface thereby facilitating the smooth flow of traffic.

7. Disadvantages of Camber in Road Pavement

Some of the disadvantages of providing camber in the road pavements can be listed as follows:

a. The construction of camber increases the possibility of wearing of the middle portion of the pavement due to the increased tendency to travel from the middle of the highway pavement. This increases the loading on the middle portion.

b. The provision of camber subsequently decreases the road width.

c. The possibility of the accident also increases due to camber in highway pavements.

| Read More: Flexible Pavement |

| Read More: Rigid Pavement |