Table of Contents

In this article, we will discuss air entraining cement.

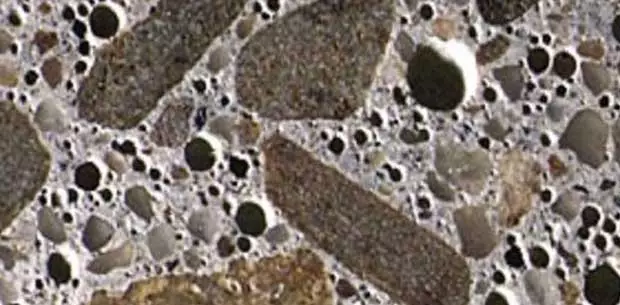

The process which concerns the introduction of small air bubbles into concrete is known as air entrainment. And the concrete prepared through this procedure is called air-entrained concrete also the portland cement used is called Air entraining cement.

Utilizing air-entraining Portland cement or air-entraining mechanisms such as admixture, air entrainment is accomplished in concrete. The quantity of air in such concrete is commonly between 4 to 7% of the volume of concrete.

It is calculated by the galvanometric method, volumetric method, and pressure method. The air bubbles reduce internal pressure on the concrete by supplying chambers for water to develop when it freezes.

The manufacture of air-entraining concrete is similar to that of normal ordinary portland cement, after the cement clinkers are formed, in the grinding process the cement clinkers are added with some air-entraining materials which make the cement air-entrained cement.

The ways of containing air in concrete are as follows:

a. Utilizing gas-forming materials such as aluminum powder, zinc powder, and hydrogen peroxide.

b. Using surface-active agents that decrease surface tension. They may be natural wood resins and their soaps, animal or vegetable fats or oils, and alkali salts of sulfonated or sulfated organic compounds.

c. Utilizing cement dispersing agents.

d. Calcium lignosulfonate and Calcium salts of glues.

1. Characteristics of Air Entraining Concrete

The following are characteristics of air-entraining concrete:

1. Workability

The workability possessions of this cement are high due to the air bubbles which work as lubricants between aggregates, which decreases water and sand necessities and hence improves the strength of the concrete. It else reduces segregation and bleeding of plastic concrete.

2. Strength

According to Abraham’s law, the Strength and the W/C ratios are inversely proportional to each other.

Less the W/C ratio, the higher the strength. With the utilization of air-entrained, the W/C ratio is kept low and hence the strength parameter of the concrete is not compromised. But it is hard to achieve high-level strength concrete with air-entrained cement.

3. Freezing and Thawing Durability

In the cold environment, due to low temperature, the water inside the concrete froze and expands. The utilization of this cement supplies the needed area for the water to expand and thus doesn’t let the concrete crack.

However, entrained air bubbles serve as reservoirs for the boosted water, thereby reducing expansion pressure and stopping concrete damage.

4. Sulphate Resistance

The withstand ability for sulphate attack is high in the air-entrained cement as the W/c ratio can be maintained down, which begins the sulphate attack.

5. Permeability

The permeability of air-entrained concrete is greater than that of non-air-entrained concrete as the air bubbles break the capillary channels.

Therefore, utilize air-entrained concrete where water tightness is a necessity.

6. De-Icing Resistance

In the sloped structure, the ice is formed on the building. To clear this ice, de-icing chemicals are utilized for snow and ice removal. The use of these chemicals forms a layer of scales in the concrete.

Air-entrained cement stops scaling induced by de-icing chemicals and is suggested for all applications where the concrete contacts de-icing chemicals.

2. Advantages of Air Entraining Cement

The advantages of air-entrained concrete are as follows:

a. Workability of concrete gets a boost.

b. It decreases the effect of freezing and thawing.

c. Bleeding, segregation, and laitance in concrete decrease.

d. Entrained air enhances the sulphate withstanding ability of concrete.

e. Decreases the chances of shrinkage and crack formation in the concrete surface.

3. Disadvantages of Air Entraining Cement

The disadvantages of air entraining cement are as follows:

a. The strength of concrete drops.

b. The use of an air-entraining agent increases the porosity of concrete thereby reducing the unit weight.

c. Air entrainment in concrete must not be performed if the site control is not good.

d. The air entrained in concrete changes with the difference in sand grading, errors in proportioning, and workability of the mix and temperatures.

| Read Also: Aerated Concrete |