Table of Contents

It is the process of bringing water to contact with atmospheric air that contains oxygen.

Aeration is one of the important operations for making water healthy and pure.

Aeration can also be defined as the process of supplying air into water or wastewater to permit aerobic biodegradation of organic materials.

The principal secondary treatment techniques employed are the trickling filter and the activated sludge process which are usually categorized as fixed-film or suspended-growth systems respectively.

1. Purpose of Aeration

The purposes of aeration are as follows:

1. To remove taste and odor by gases due to organic decomposition.

2. To increase the dissolved oxygen.

3. To remove hydrogen sulphide that causes odor.

4. To decrease carbon dioxide in water.

5. To kill the bacteria to some extent.

2. Methods of Aeration

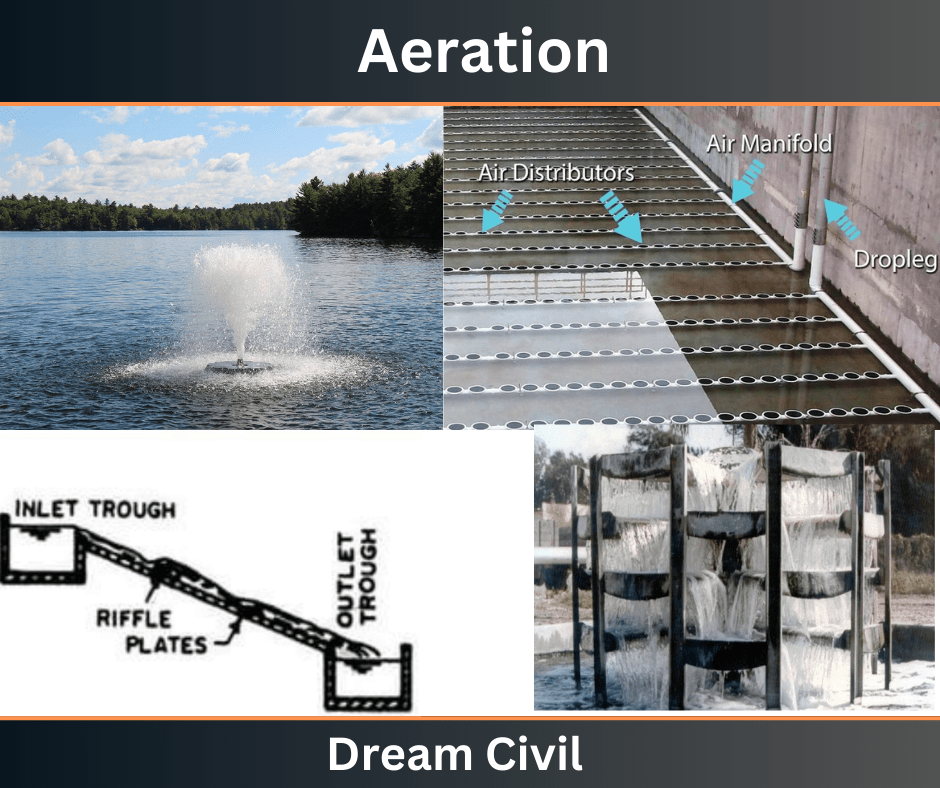

Aeration is done by following the main types of Aerators:

a. Freefall Aerators

i. Cascade Aerators

a. It is the simplest of the freefall aerator.

b. It can be built of concrete or metal.

c. The height of this aerator is kept at about 1 in 3.

d. 50 to 60%, CO2 reduction.

ii. Inclined Aerators

a. In this aerator waterfalls along an inclined plane/apron.

b. Breaking up of water due to apron cause agitation.

c. Agitation increases the contact between air and water.

iii. Slat Tray Aerators

a. It consists of closely stacked superimposed wood slat trays.

b. Water is spread evenly on the top tray.

c. Water trickles from one tray to another.

d. Air is supplied at the bottom with the help of a blower.

e. Ventilator discharges to air and gases.

iv. Gravel Bed Aerators

a. Water is sprayed at the top and it tickles down the bed of the coke or anthracite.

b. The thickness of the gravel bed is 1 to 1.5 m.

b. Spray Aerators

The system includes more spray nozzles, which are attached in a pipe, similarly many set of pipes are well attached like square, circle, and rectangle-shaped form and those bunch of pipes ultimately connects to a common pipe manifold, that pipe grid encountered over an open-top tank

The water exits each nozzle in a fine spray and drops through the surrounding air, making a fountain effect, so simply it is called waterfall type.

Spray aerators are majorly excellent with respect to gas transfer such as carbon dioxide removal or oxygen addition.

c. Air Diffuser Aerators

Air is introduced into the liquid being aerated in the form of a bubble which normally raise through the liquid. Taste and Odor producing gases are absorbed by the air bubbles giving in turn oxygen to water.

3. References1. Content Filter & Authenticity Checking Team, Dream Civil International (Our team checks every content & detail to maintain quality. ) |

Read Also: Best Architecture 3D Modeling Software