Table of Contents

1. What are Hollow Blocks?

✔ Hollow Blocks are Concrete blocks typically known as concrete masonry units (CMUs) with one or more cavities and are often directed to as hollow blocks.

✔ These cavities come in square, rectangular, or circular shapes, which can be encountered either in the center or at the ends of the block.

✔ Although concrete is the preliminary material used to produce these blocks, they can also be fabricated from clay or sand.

2. What are Solid Concrete Blocks?

✔ Solid concrete blocks are commonly used, which are heavy and manufactured from dense aggregate.

✔ They are solid and provide good stability to the structures. So, these solid blocks are preferable for extensive masonry work like load-bearing walls.

✔ They are available in large sizes compared to bricks. So, it takes less time to construct concrete masonry than brick masonry.

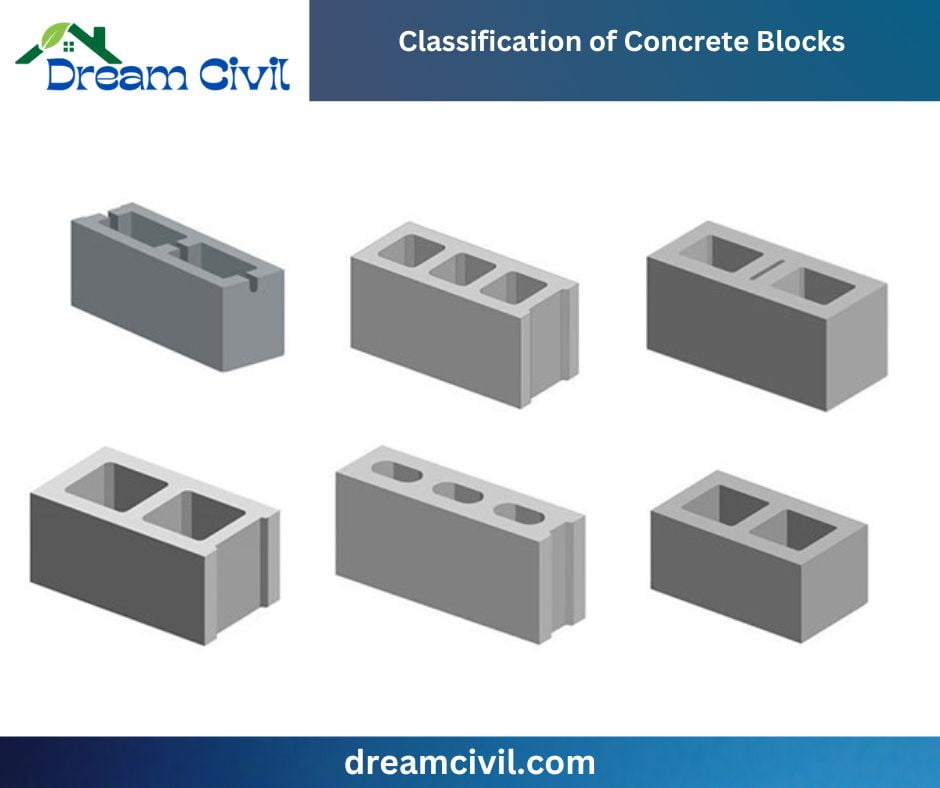

3. Classification of Concrete Blocks

The hollow concrete blocks can be categorized into the following four types:

1. Grade ‘A’ ( Hollow )

✔ These are load-bearing units and can contain the lowest block density of 1500 kg/m3. The hollow concrete blocks can be prepared for the lowest compressive strengths of 3.5, 4.5, 5.5, and 7.0 N/mm2 for 28 days.

2. Grade’ B’ ( Hollow )

✔ These are also utilized as load-bearing units and can contain a block density of 1500 kg/m3 but not less than 1000 kg/m3. These can be prepared for the lowest compressive strengths of 2.0, 3.0, and 5.0 N/mm2, respectively, for 28 days.

3. Grade’ C’ ( Hollow )

✔ These grades of concrete blocks are utilized as non-load-bearing units and can contain a block density of less than 1500 kg/m3 but not less than 1000 kg/m3. These shall be prepared for the lowest average compressive Strength of 1.5 N/mm2 at 28 days.

4. Grade ‘D’ ( Solid )

✔ Solid concrete blocks can contain a block density of a minimum of 1800 kg/m3. These can be prepared for the lowest compressive strengths of 4.0 and 5.0 N/mm2, respectively.

4. Technical Detail about Hollow Blocks:

| Aspect | Details |

|---|---|

| Dimensions | ✔ Common sizes: 8 inches (height) x 8 inches (width) x 16 inches (length) ✔ Standard sizes: 4 inches (height) x 8 inches (width) x 16 inches (length) |

| Composition | ✔ Main materials: Portland cement, aggregates (sand, gravel, crushed stone), water ✔ Molded mixture to create block shape |

| Cavity Size and Arrangement | – Hollow blocks have varying sizes and configurations of voids to reduce weight while maintaining structural integrity. |

| Types of Hollow Blocks | ✔ Classified by density, Strength, and purpose: lightweight, medium-weight blocks with specific properties and applications. |

| Compressive Strength | ✔ Measured in psi (pounds per square inch) or MPa (megapascals) ✔ Strength varies based on composition and manufacturing process. |

| Density | ✔ Lightweight blocks have a lower density, suitable for insulation. ✔ Heavyweight blocks are denser and used for load-bearing applications. |

| Fire Resistance | ✔ Hollow blocks are fire-resistant, with fire ratings based on type and thickness. |

| Sound Insulation | ✔ Sound insulation properties vary based on block design, including cavity arrangement and thickness. |

| Thermal Insulation | ✔ Lightweight blocks provide some thermal insulation, with the option to enhance performance by adding additional materials. |

| Manufacturing Standards | ✔ Manufactured following industry standards and codes, which may vary by region and country. |

| Quality Control | ✔ Manufacturers implement quality control measures, including strength and density testing, to ensure blocks meet specified standards. |

| Installation | ✔ Proper installation techniques, including mortar selection and joint spacing, ensure structural stability and integrity. |

5. What are the Standard sizes of Hollow Block?

✔ 39 cm x 19 cm 30 cm is the standard size of hollow concrete blocks.

✔ 39 cm x 19 cm x 20 cm and 39 cm x 19 cm x 10 cm is the standard size of hollow building tiles.

✔ Water absorption will be less than 10% in hollow solid block blocks for partitioning.

6. What are the properties of Hollow Block?

1. Moisture Movement: Not more than 0.09%

2. Water Absorption: Not more than 10%

3. Drying Shrinkage: Not more than 0.06%

4. Compressive Strength: Approximately 2,000 to 4,000 psi

5. Density:

For Grade A: 1500 kg/m3

For Grade B: 1100 kg/m3 to 1500 kg/m3

7. What are the uses of hollow blocks?

Hollow concrete blocks are utilized in all types of masonry construction, such as:

✔ It is used in exterior load-bearing walls

✔ It is used in interior load-bearing walls

✔ It is also used in curtain walls

✔ It is used in partition walls and panel walls

✔ Backing from brick, stone, and other facing

✔ Fireproofing over a structural member

✔ Fire-safe walls around stairwells, elevators

✔ Piers, column and retaining walls, etc.

✔ Boundary fences

8. What are the advantages and disadvantages of hollow blocks?

Advantages

✔ These blocks are more cost-effective than traditional wall or wall construction systems.

✔ Solid, hollow blocks need less maintenance, insulation from sound and heat, and are fire-resistant.

✔ The joints in these blocks need less cement mortar and little or no plastering, thus speeding up the construction process and saving costs.

✔ It provides high dimensional accuracy and a consistent finish, making it an ideal building material for building load-bearing structures and partition walls.

✔ These hollow concrete blocks have high-stress bearing capacity and are widely used in building construction practices.

✔ The hollow blocks are lightweight and utilized in building earthquake-prone homes.

✔ The hollow block will provide a various look as it decreases the energy bill to produce an environmentally friendly environment in the building.

✔ Hollowing space in blocks prepares masonry work soundproof, heatproof, and damp proofing.

✔ It is fully energy-efficient and requires no non-renewable resources for its manufacture.

✔ Also, it does not disturb the ecosystem, so they are either environmentally friendly or eco-friendly since the waste and local resources can be used for manufacturing or production.

✔ It can also be prepared at the site.

✔ It is of high quality, Strength, uniform size, and shape.

Disadvantages

✔ Maintenance cost is high.

✔ Concrete blocks have a low bearing capacity as the average mass of wall decoration materials is reduced, and the load-bearing capacity is usually decreased.

✔ It is hazardous to hang huge things on walls.

✔ Hollow blocks are porous, so there is a high chance of water seepage.

9. Cost of Hollow Blocks

✔ The cost of hollow blocks varies from one country to another. The rate of blocks can get high if the rate of cement, sand, and aggregates gets high.

Here is the average cost of concert blocks in different countries:

✔ In India, the cost of hollow blocks is around Rs 28/Piece.

✔ In Nepal, the cost of hollow blocks is around Rs 86 for a 4-inch wide.

✔ In the USA, the cost of hollow blocks is around 1$ to 3 $ per block.

✔ In the Philippines, the cost of hollow blocks is around ₱15.00 – ₱23.00.

✔ In Canada, the cost of hollow blocks is around CA ( $1.93 to $3.29 ).

10. Difference Between Hollow Blocks and Solid Concrete Blocks:

| S.No | Solid Concrete Blocks | Hollow Blocks |

| 1. | Solid in Nature. | Hollow in Nature. |

| 2. | More in weight. | Less in weight. |

| 3. | The conductivity of heat is high (less thermal insulation) | The conductivity of heat is low (more thermal insulation) |

| 4. | It doesn’t provide a facility to conceal conduits, etc. | It provides a facility to conceal conduits, etc. |

| 5. | Lean mixes are used. | Needs a richer mix. |

| 6. | No fine concrete is used. | Fine aggregate is more (as high as 60%) |

11. Most-Asked Question about hollow blocks:

1. How much concrete to fill hollow blocks?

✔ Filling 150 mm ‘H’ blocks permits 0.65 m3 of concrete per 100 blocks. Filling 200mm blocks permits 0.8 m3 of concrete per 100 blocks.

✔ To fill, 200mm ‘H’ blocks permit 0.84 m3 of concrete per 100 blocks.

2. How many hollow blocks are in 1 square meter?

✔ The total number of 10 blocks is 1 m2.

3. How much is a hollow block in the Philippines?

Note: All prices are in Php.

| Concrete Hollow Block Wall Masonry Work | ||

| Concrete Hollow Blocks (CHB) 4″ | pc | 12.00 |

| Concrete Hollow Blocks (CHB) 6″ | pc | 18.00 |

| Portland Cement, 40 kg. | bag | 261.00 |

| Washed sand | m3 | 1,365.00 |

| 10 mm. Dia. x 6.0 M. DSB | pc. | 159.00 |

| Tie Wire #16 | kg. | 61.00 |

| Stone Masonry Works | ||

| Cement | bag | 262.00 |

| Sand | m3 | 1,432.00 |

| Gravel Fill | m3 | 1,417.00 |

| Weep Holes (PVC) | Lm. | 201.00 |

| Filter Cloth | m2 | 260.00 |

| Boulders | m3 | 1,482.05 |

| Screened Sand | m3 | 1,550.00 |

| Screened Gravel | m3 | 1,590.00 |

4. How to make hollow blocks?

The process of preparing hollow blocks is as follows:

✔ The ratio of 1:2:3 is prepared of the cement, sand, and gravel in the mold flows water until the concrete mixture is sufficient to flow into the container (mold).

✔ Blend the water into the mold.

✔ Use a steel rod to stir the mixture regularly.

✔ Now, leave the block to dry for 1-2 days; as a result, hardened hollow blocks are prepared for construction work.

5. How to anchor into a hollow cinder block?

✔ When drilling into a cinder block to keep a concrete anchor, a hammer drill should be utilized with a drill bit that has a carbide tip.

✔ Drilling into the solid section does not make or raise any problems when utilizing a masonry bit. The hammer drill will make the hole effortlessly into the cinder block.

| Read Also: Block Wall Calculation |

| Verified by: Er. Bipana Kshetri Puri |