Table of Contents

1. Overview

Bricks are the oldest and useful construction materials used all over the world for masonry constructions.

Due to the immense importance of bricks in such types of constructions, it is necessary to determine the suitability and quality of bricks.

Hence, several tests on brick must be carried out to ensure the structure to be constructed have adequate strength and stability.

Such tests on bricks are carried out in various phases of construction.

Some of the important types of tests carried out to determine the suitability and quality of bricks are briefly described below:

2. Types of Tests on Bricks

1. Absorption Test on Brick

The absorption test is the type of test conducted on bricks to determine the moisture absorbed by the bricks when subjected to extreme conditions.

The absorption test can be used as an indicator of the durability properties of bricks such as quality, degree of burning and behaviour of bricks in weathering.

The test can be briefly explained as follows:

Apparatus Required

1. A ventilated oven

2. A weighing balance with a sensitivity of less than 0.1%

3. Sample of whole bricks

Procedure

The procedure for the absorption test on bricks includes the following series of steps:

i. The brick specimen is first dried in the ventilated oven at a temperature ranging from 105 degrees Celsius to 115 degrees Celsius until the specimen attains a constant mass.

ii. The heated specimen is then allowed to cool at room temperature.

iii. The specimen is weighed and its mass is recorded ( M1).

iv. Then, the specimen is immersed in water at a temperature of about 27 degrees Celsius for 24 hours.

v. The brick specimen is taken out from the water and wiped with a clean cloth to remove the traces of water that may be present.

vi. The specimen thus obtained is then weighed (M2).

Calculation of Water Absorption of Bricks

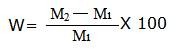

Water absorption by the brick specimen is given by the formula,

The average result shall be reported.

where,

M2 = Wet Weight of brick after immersion of brick in water for 24 hours

M1 = Dry Weight after oven drying of brick at 105-110 deg. C

Result

Water absorption of the given bricks = ………….%

| S.N. | Brick Class | The maximum water absorption percentage |

| 1. | First | 20% |

| 2. | Second | 22% |

| 3. | Third | 25% |

| 4. | Heavy-duty machine made bricks | 5% |

2. Crushing Strength or Compressive Strength Test on Brick

Bricks that are used for masonry construction are generally subjected to compressive loads thus it is necessary to determine the compressive strength of bricks.

The compressive strength test is also known as the crushing strength test which is an important type of laboratory test conducted on bricks to determine the load-carrying capacity of bricks when subjected to a compressive load.

This test is performed utilizing a compression testing machine.

The test can be briefly explained as follows:

Apparatus & Materials Required

1. Compression Testing Machine

2. Sample of whole bricks

3. Cement, sand, aggregate for specimen preparation

Specimen Preparation

The samples of whole bricks are first taken and the unevenness is removed.

The dimensions are duly measured.

The samples are then immersed in water for 24 hours at room temperature. After 24 hours, the specimen is removed and dried.

If traces of water are still present, it is wiped out with a clean cloth.

Then, cement mortar is prepared and the frog of the specimen is filled with the prepared cement mortar.

Any voids present are also filled with cement mortar.

The mortar filled bricks specimen is then stored in damp jute bags for 24 hours.

Keep the bricks in water for 3 to 7 days. This is to permit the mortar to harden.

Procedure

The procedure for the crushing strength test on bricks involves the following series of steps:

1. The specimen with the mortar filled face upwards is placed in the plates of the compression testing machine.

2. The load is then applied axially at a uniform rate of 14N/ mm² per minute until failure occurs. The maximum load at failure is recorded.

3. The compressive strength is then calculated using the following formula:

Compressive Strength= Maximum load at failure / Average Area of Bed Face

3. Soundness Test of Brick

A soundness test on bricks is carried out to determine the nature of bricks when subjected to sudden impact.

It is a simple test in which two bricks are taken randomly from the stack of bricks.

The bricks are then struck against each other.

If it emits a clear metallic ringing sound; the brick is of good quality.

| See about Types of Pipes in Civil Engineering & Construction: Tap Here |

4. Hardness Test on Brick

The hardness of bricks generally implies the resistance of bricks to scratch.

For this test, the brick is scratched with a sharp tool or fingernail.

If the scratching does not leave behind any impression on the brick, it is considered as a hard brick.

5. Shape and Size Test on Brick

To maintain uniformity in the construction, the bricks must be of proper shape and uniform size.

A good brick must have a proper rectangular shape with sharp edges.

For this test, about 20 bricks from the stacked bricks are taken.

The samples taken are then stacked along the length, breadth and height and duly compared.

If all the bricks are of similar size, then they can be used in construction works.

6. Colour Test of Brick

The Colour test of bricks simply involves the visual examination of bricks for acceptable bright uniform colour throughout the body of the brick.

| See about Parapet Wall & Its Types: Visit Here |

7. Structure Test of Brick

Structure test of bricks includes the process of breaking the brick followed by the observation of the inner portion of brick clearly to check the homogeneity and presence of lumps.

8. Efflorescence Test on Brick

A good brick should be free from soluble salts.

The presence of soluble salts in the bricks leads to efflorescence on the bricks thereby decreasing the quality of bricks.

To carry out the efflorescence test on bricks, the sample bricks are taken and immersed in water for 24 hours.

Then, the specimen is allowed to dry in shade.

After complete drying, the specimen is thoroughly observed.

If any white or grey patches are seen on the brick surface, it indicates the presence of soluble salts and is not suitable for construction.

| Read Also: Profometer Test |