Table of Contents

In this article, we will discuss pipe joints.

1. Introduction

For the ease in handling, transporting, and placing in position of pipe, these are manufactured in suitable length hence pipe should be jointed. A joint may require at a bent to change the direction of the pipe or to connect pipe for the continuation of a pipeline which device is called the pipe joint. These pipe joints should be watertight, strong durable, and economical.

2. Types of Pipe Joint

In a water supply system network of long pipelines is required for the conveyance and distribution of water. Pipes are not manufactured in a single length as they may be long as 200 in coils of HDPE and other pipes are commonly 2 to 6 m.

Hence these pipes are required to join together of smaller length. Pipe joints are of various types which depend on pipe materials, the resistivity of pressure, durability, water tightness, site conditions, etc.

Pipe joints commonly used in pipelines are as follows,

1. Socket and spigot (bell and spigot joint)

2. Flanged

3. Expansion

4. Collar

5. Screwed and socket

2.1. Socket and Spigot Joint

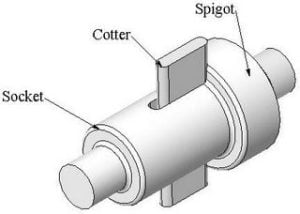

This joint as shown in figure 8-1 is commonly used for CI pipes as well as DI pipes. In this joint spigot of one end of the pipe is slipped in socket or bell end of other pipe and jute or hemp yam is wrapped around spigot tightly up to 50 mm depth and a gasket or joint runner is clamped in place of the round joint to fit tightly.

With the help of a chalking tool, molten lead poured into the V shape opening left on the top by clamped joint runner. Space between hemp yam and the clamped runner is filled with molten lead.

Now runner is removed after hardening of lead then tightened by chalking tool and hammer. Lead about 3.5 to 4 kg may be required for up to the diameter 150 mm and for diameter 120 cm pipe 40 to 45 kg per joint. It takes high cost but makes joint perfect.

2.2. Flanged Joint

This joint is commonly used for CI pipes, steel pipes, and GI pipes This joint as shown in figure 8-2 may be used for temporary works. so that it can easily assemble and dissemble.

The flanges of both pipes are brought together and placed gasket in-between it is water tightened by screw or welding. This joint is suitable for pumping station filter plants, laboratories, and boiler houses but not used in places having vibration and deflection.

| Read Also: Pipe Material |

2.3. Expansion joint

This joint can bear temperature stress which results in expansion and contraction. The function of this joint is to maintain the water-tightness of the joint due to stress produced by temperature variations.

The socket end is flanged with a cast iron follower ring which can be freely slid on the spigot end and a rubber gasket is tightly pressed between the annular space of the spigot and socket by means of the bolt.

Water-tightness is maintained by the rubber gasket during slight movement of socket end in forwarding and backward directions due to temperature stress.

2.4. Collar joint

This joint is commonly used for cement concrete pipes; both reinforced and pre-stressed concrete pipes with plain ends. Tow ends of pipes are brought in the same level with a rubber gasket in-between, the collar is placed with a lap on both pipes. Cement mortar (1:1) is filled between the space of collar and pipe.

| Read Also: Types of Valves |

2.5. Screwed and Socket

Screwed and socket joint is commonly used for GI pipes and also for small diameter steel pipes. The ends of both pipes have screw threads on the outer surface in which sockets are screwed to make the joint.