Table of Contents

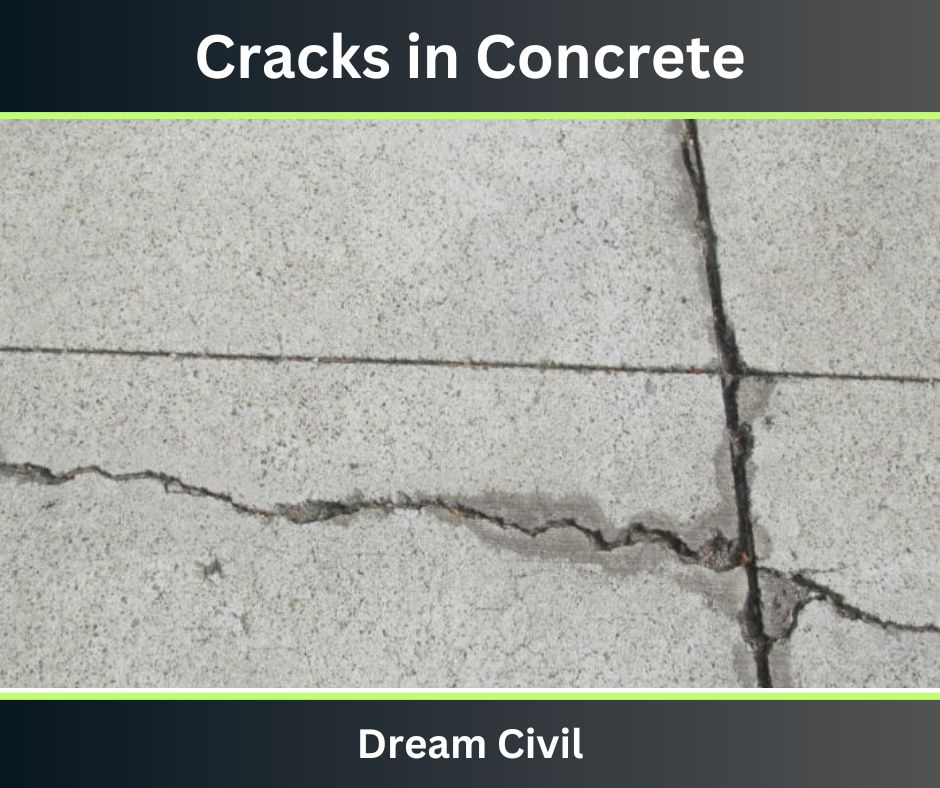

| In this article, we will discuss 6 types of cracks in concrete with their causes and prevention methods. |

Concrete is a composite material consisting of a mixture of fine aggregate, coarse aggregate, and binding material.

The binding material may be hydraulic cement such as Portland cement or Calcium Aluminate Cement, Lime, Putty, etc.

✔ Concrete is a widely used type of construction material. Despite its immense importance, the absence of proper technique and maintenance and several external factors may pose a great threat of cracking in the concrete.

✔ Cracks in concrete are a very common defect and are almost inevitable. However, the extent or degree to which cracks are formed can be controlled by various techniques.

1. Types of Cracks in Concrete

The common type of cracks in concrete can be summarized as follows:

i. Plastic Shrinkage Crack

Plastic Shrinkage Crack is developed during the initial stage, i.e. before hardening.

It is caused by a rapid loss of water from the surface of the concrete before it has been set.

This crack generally occurs on horizontal surfaces than on vertical.

✔ When the concrete is in the plastic state, it contains enough water before hardening. Eventually, the water evaporates before setting, leaving behind voids between the aggregate particles. The voids or the empty spaces thus formed weaken the concrete increasing the possibility of cracking.

✔ Such crack originates from the corner of slabs and spreads throughout the slab’s thickness.

Causes of Plastic Shrinkage Crack

✔ Plastic shrinkage crack is caused by a rapid water loss from the surface of the concrete before it has been set.

✔ The condition exists when the surface moisture evaporation rate exceeds the rate at which rising bleed water can replace it.

Water receding below the concrete surface forms menisci between the cement and aggregate particles, causing a tensile force to develop in the surface layers.

If the concrete surface has started to set and has developed sufficient tensile strength to resist tensile forces, cracks do not form.

The main causes of plastic shrinkage cracks can be listed as follows:

1. Low relative humidity.

2. High ambient temperature.

3. High wind velocity.

Prevention of Plastic Shrinkage Crack

The various precautions that must be taken to prevent plastic shrinkage cracks are mentioned below:

1. If a harsh climatic condition exists at the site, such as high wind velocity or hot temperature, the placement must be done at an appropriate time, such as late evening or early night.

2. In very hot or dry conditions, fog sprays must be used. Fog spray reduces the rate of evaporation of water.

3. Proper workmanship, equipment, and materials must be ensured.

4. The concrete must be covered with wet burlap or polyethene sheets between finishing operations.

ii. Expansion Concrete Crack

The cracks associated with the expansion of concrete are known as expansion concrete cracks.

✔ These are the type of cracks formed due to the expansion of concrete, particularly in hot climatic conditions.

✔ Due to the extreme heat, the concrete begins to expand, and it pushes away anything present in its way, such as a brick. Since neither of them can flex, the resulting expanding force is so strong that it can cause cracking of the concrete.

Causes of Expansion Concrete Crack

Some of the causes of the expansion of concrete cracks can be listed as follows:

1. Wrong choice of materials.

2. Excessive temperature fluctuations ( Alternate hot and cold cycle ).

3. Not using the appropriate methods for construction.

Prevention of Expansion Concrete Crack

Some of the preventive measures that must be adopted to prevent the cracking are as follows:

1. Application of expansion joints made up of asphalt, rubber, etc.

2. Selection of appropriate placement methods.

iii. Heaving Concrete Cracks

Due to the alternate freezing and thawing cycle, heaving concrete cracks are formed.

✔ Normally, the ground rises when it freezes and settles back down during thawing.

If the concrete associated with the soil does not rise and subsequently settles down with the soil, then cracks may also develop in it.

Moreover, the deep spreading roots of trees may also cause a similar rise of the ground, forming heave cracks.

Causes of Heaving Concrete Cracks

Some of the causes of heaving concrete cracks can be listed as follows:

1. Alternate freezing and thawing cycle.

2. Roots of the trees.

3. Abnormal soil condition causing uplift.

Prevention of Heaving Concrete Cracks

Some of the preventive measures to prevent such cracks are as follows:

1. Adequate planning to minimize such causes.

2. Placing concrete in a suitable location as far as possible.

iv. Settling Concrete Cracks

✔ Settling concrete cracks are the cracks that are associated with the settling of the soil.

It is the type of crack caused by the reverse action than heave cracks, i.e. due to settling the soil.

✔ As mentioned earlier, the roots of trees can be a prime source of the crack in the concrete. When a tree is uprooted, voids are formed between the concrete particles, forming cracks.

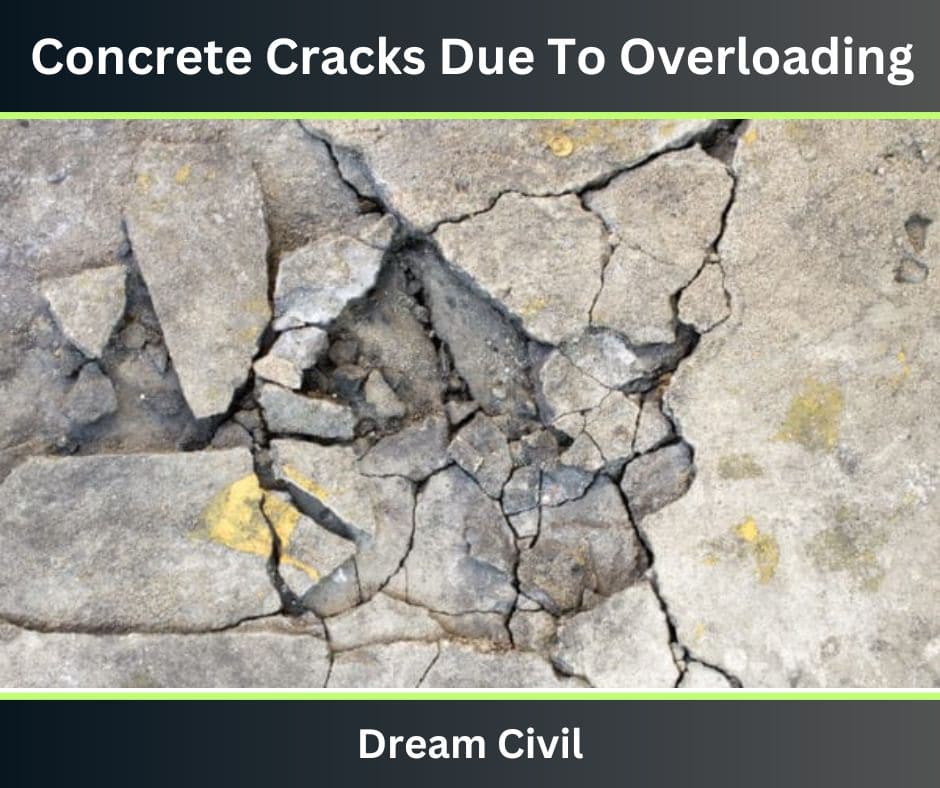

v. Concrete Cracks Due To Overloading

✔ Although concrete gains adequate strength after curing, cracks may develop on it if subjected to excessive load for a long time.

✔ Such cracks on concrete that are formed due to the inability of concrete to withstand the excessive stress imposed are known as concrete cracks due to overloading.

Causes of Concrete Cracks Due To Overloading

Some of the causes of such cracks are listed as follows:

1. Overloading on concrete.

2. Softening of concrete after heavy rainfall or snow.

3. Insufficient curing of concrete.

Prevention of Concrete Cracks Due To Overloading

Some of the preventive measures that can be adopted to avoid such cracks are as follows:

1. Adequate curing of concrete.

2. Proper maintenance of concrete, particularly in harsh weather.

3. Avoid continuous overloading of concrete.

vi. Concrete Crack Due To Premature Drying

✔ There are two types of cracks associated with premature drying, i.e. crusting cracks and crazing cracks.

✔ Crazing cracks are the type of cracks that appear as fine lines and mostly resemble a web of spiders.

On the other hand, crusting cracks are the type of cracks that occur due to the stamping process. The stamping process is the process of giving a certain texture to the concrete.

Causes of Concrete Crack Due To Premature Drying

Some of the causes of cracks due to premature drying can be listed as follows:

1. Improper mixing of concrete.

2. Excessive evaporation of moisture from the surface of the concrete.

3. The sunny or windy climatic condition causes premature concrete drying.

4. Improper stamping technique.

Prevention of Concrete Crack Due To Premature Drying

Some of the preventive measures that may be adopted to prevent such type of cracking can be listed below:

1. Use of a quality mix.

2. Proper workmanship.

3. Application of appropriate concrete finishing technique.

2. Conclusion

Most concrete cracks result from improper curing and improper mix.

So, curing should be done for a minimum of 14 days ( best to do it for 28 days ).

Concrete mix design should be done according to the type of construction. This prevents overloading cracking and also increases the durability as well as the resistivity of concrete.

3. References1. Content Filter & Authenticity Checking Team, Dream Civil International (Our team checks every content & detail to maintain quality.) |

Read Also: Types of Concrete